In the age of Industry 4.0, "visibility" goes beyond what meets the eye. Smart factories are now leveraging sensors, IoT and data analysis to monitor and optimize every aspect of their operations, including the precise management of the invisible industrial gases that are crucial to key processes. From small workshops to large-scale manufacturers, businesses are adopting these technologies to build smarter, more efficient workflows.

Real-time process monitoring

Precise control of the delivery of industrial gases is essential for many processes, demanding continuous oversight to maintain efficiency and safety. Real-time monitoring is vital to ensure industrial gases remain within specified parameters, supporting smooth and reliable operations. Without proper monitoring, companies risk equipment failures, safety hazards, diminished product quality, increased waste and costly disruptions to productivity. Smart, connected systems are transforming this process by providing continuous, real-time updates. These systems utilize visual indicators on devices and transmit signals to control systems for remote monitoring and management.

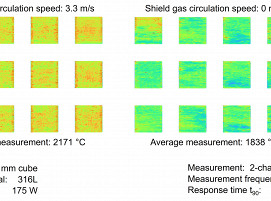

Witt Dome Press Regulator 757 LE/S with Smart option ensures precise gas pressure control with real-time monitoring of pressure, temperature and flow. Its integrated pilot pressure regulator design reduces costs while enabling internal system integration for optimized. They instantly detect deviations in key factors like pressure, flow rates, mixture ratios, temperature and gas purity, triggering alarms to halt operations before minor issues escalate into major problems. Early warnings allow operators to address potential concerns proactively, enabling smarter, condition-based preventive maintenance. Beyond their operational advantages, these advanced systems also contribute to lower gas consumption, reduced defects and waste and enhanced workplace safety. They promote environmental sustainability while driving operational performance.

Automation and remote control

Some advanced valves offering visual indicators and data transmission as well as remote control capabilities, whether operated by personnel or automated systems. For instance, automated electric mixing valves provide several advantages. They enable precise adjustments, delivering greater accuracy and control compared to manual operation. This ensures a reliable and consistent gas mixture, which is essential for maintaining uniformity in experiments or production processes. The electronic controls also make it easy to reproduce specific gas mixtures, ensuring consistency across different applications.

This precision and flexibility are especially valuable in production environments that demand adaptability, such as laser cutting. Switching between different cutting conditions – such as the quality of the cut, the material's thickness and the speed at which the laser moves. Automated mixing valves simplify these adjustments, enhancing both efficiency and performance.

Driving continuous improvement

Intelligent gas valves and mixers also provide detailed data for analysis, enabling businesses to uncover insights that drive continuous improvement. By tracking trends, addressing quality concerns, ensuring traceability and identifying inefficiencies, businesses can optimize their operations and make informed, data-driven decisions. This is especially critical in industries where precise gas control is essential to maximize efficiency and ensure consistent product quality.

The critical role of industrial gases

Industrial gases play a vital role across many industries. Processes like laser cutting and arc welding depend on precise gas delivery to achieve consistent, high-quality results. Accuracy is everything. Proper management of gas pressure, flow rates, and mixtures – such as argon (Ar), helium (He) , nitrogen (N2), carbon dioxide (CO2), and oxygen (O2) – can significantly impact success. For example, precise shielding gas dosing and delivery improves gas metal arc welding (GMAW) efficiency, boosting welding speed, extending duty cycles and reducing cleanup time.

Welding

Consistently delivering precise amounts of shielding gas is crucial for achieving efficiency and reducing costs for GMAW. The proper gas mixture can boost welding speed, increase duty cycles and minimize cleanup time. Key factors like heat transfer, oxidizing potential, and metal transfer characteristics determine welding performance. For example, high-thermal-conductivity gases create hotter, more fluid weld puddles, while high-oxidizing gases enhance weld coalescence. Argon-based blends allow for spray transfer, achieving higher deposition efficiency and travel speeds compared to carbon dioxide. Using argon blends reduces spatter, preventing nozzle blockages and wire feed issues common with carbon dioxide shielding. This results in longer welding cycles and less downtime for cleanup. WITT Gas mixers supply mixed gases conforming to AWS 5.32 for weld shield gases per the AWS code or ISO 14175 gas mixtures for fusion welding and allied processes. Each mixer is supplied with a factory test certificate, plus the mix ratio can be audited in real time or saved on a local PC or integrated network.

Smart, connected industrial gas solutions

The advancements in smart, connected valves have transformed industrial gas applications, providing levels of precision and control. These state-of-the-art valves are equipped with sensors and IoT-enabled technologies, allowing real-time monitoring and remote management of gas flow and pressure. By integrating these sophisticated systems, industries can enhance safety, optimize efficiency, and reduce operational costs. Such innovations are paving the way for smarter, more sustainable welding and gas handling solutions.

Example: smart dome pressure regulators

Dome pressure regulators are preferred to spring-loaded types for most manufacturing applications due to their exceptional gas pressure stability. Instead of relying on steel springs, dome regulators use a gas cushion to maintain constant working pressure, even during inlet pressure fluctuations or varying gas withdrawal rates. This ensures greater process, safety and stability, making them ideal for high-performance applications.

WITT has advanced dome pressure regulator technology by integrating the pilot pressure and regulator into a single, ready-to-use valve. This reduces installation and maintenance costs while allowing for operation with an electrical proportional valve, enabling external control system integration. WITT’s smart dome pressure regulators take performance further by incorporating sensors to measure gas pressure and temperature at both inlet and outlet. They calculate real-time gas flow, transmitting precise data for process optimization, safety, and transparency. These innovations ensure consistent pressure control, even with minimal pressure differences, making them perfect for demanding industrial processes. Additional safety and performance can be achieved with WITT’s Coldstop Smart, which now detects critically low temperatures and stops gas flow to safeguard piping. It is specifically designed to protect downstream equipment and piping from brittle fractures.

Protection for Cryogenic Systems

Coldstop Smart addresses a critical challenge in cryogenic gas applications – minimizing the risk of excessively low temperatures in the gas pipework downstream of the vaporizer, which can cause brittle fractures in mild and carbon steel equipment. It features integrated technology consisting of the WITT smart dome-loaded pressure regulator, solenoid valves and control unit. This solution stops the gas flow immediately if the temperature falls below a defined setpoint value and restarts as soon as the previously configured setpoint state is reached again. This ensures protection against brittle fractures, enabling companies to meet the relevant EIGA, CGA, and AIGA standards for cryogenic vaporization systems.

(Source: WITT Gas Controls LP)

Schlagworte

Arc WeldingGas Metal Arc WeldingGMAWIoTLaser CuttingMonitoringProcessingShielding GasWelding