Prima Power, provider in sheet metal working manufacturing solutions, announces that its new Giga Laser Next 3D laser machine has won the Best Award 2025 in the Sheet Metal, Tube and Profile Processing category (Blech-, Rohr- und Profilbearbeitung), at a ceremony held during Blechexpo, Germany. The award was presented by the organizers and media partners MaschinenMarkt and Blechnet to recognize innovations in sheet metal technology.

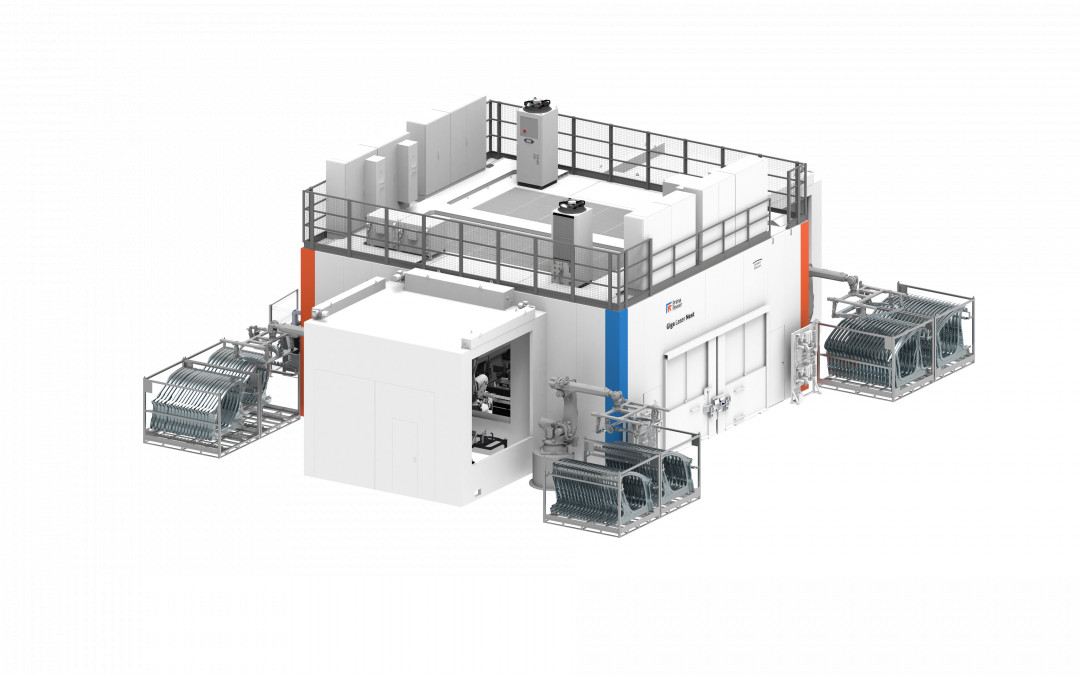

The Giga Laser Next is a 4-head 3D laser cutting system from, designed to meet the rigorous demands of high-volume, fully automated, integrated production lines in the automotive sector. The system features four synchronized laser heads that cut simultaneously on the same part, achieving up to 280 % higher productivity per square meter. It also reduces the number of cutting stations and production changeover time by an average of 75 %, enabling one-piece flow, fully unmanned automation and seamless integration into the overall production line.

At the ceremony, the award was accepted on behalf of Prima Power by Enrico Garino, Chief Marketing Officer and Head of Robotics, Johannes Pfluger, Prima Power Managing Director and Emanuele Musso, 3D Laser Product Manager.

Enrico Garino, CMO & Head of Robotics, commented: “We are deeply honoured to receive this prestigious recognition at Blechexpo. At Prima Power, we have decades of pioneering experience in 3D laser technology, continuously pushing the boundaries of what is possible. Giga Laser Next embodies our evolve by integration strategy, merging multiple functions, smarter automation and compact design into a unified, high-performance.

Emanuele Musso, 3D Laser Product Manager, added: “Giga Laser Next is more than a new product: it is a game-changing technology that inaugurates a new paradigm in 3D laser processing. By orchestrating four robust cartesian arms on a single component, we deliver unprecedented productivity, compactness and efficient automation. We believe this product will redefine customer expectations in the industry, bringing bold innovation and tangible competitive advantage.”

(Source: Prima Power)

Schlagworte

3DAwardBest Award 2025BlechexpoLaserLaser ProcessingSheet Metal