You will find the company at the fair in Hall 3, Stand 3B51.

You will find the company at the fair in Hall 3, Stand 3B51.

![SCHWEISSEN & SCHNEIDEN 2023 [EN]](/images/frontend/journals/dvs-sus_sm.png)

Cambridge Vacuum Engineering (CVE) heads to Essen for return of SCHWEISSEN & SCHNEIDEN

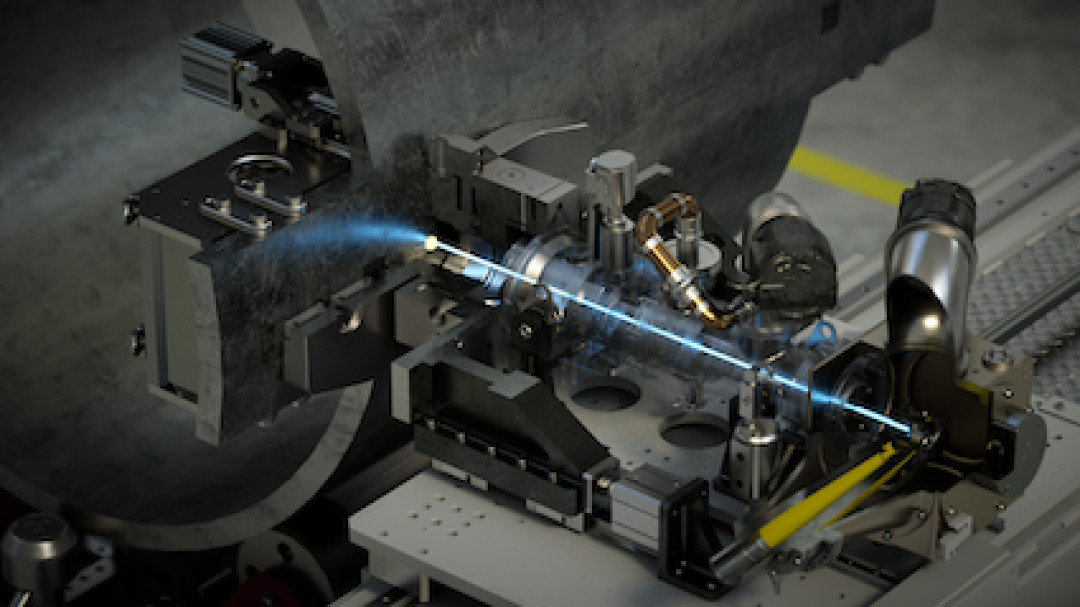

Power beam welding technologies that use electron beams and lasers to significantly speed up the manufacture of vital industrial components, will come under the spotlight at SCHWEISSEN & SCHNEIDEN next week as Cambridge Vacuum Engineering heads to Essen for the long-awaited return of the international trade fair.

At the event, CVE’s welding experts will be promoting the company’s Electron Beam, Ebflow™, Evflow™ and Laser in Vacuum welding technologies, which are substantially faster than conventional welding techniques and use much less energy. Visitors to CVE’s exhibition stand at SCHWEISSEN & SCHNEIDEN will be able to see components welded with EBW, Laser in Vacuum, Ebflow™ and Evflow™ including segments of pressure vessels, a hairpin stator from an electric vehicle motor, turbocharger shaft wheel assemblies and copper-manganin shunts.

- Electron Beam Welding (EBW) produces deep penetration welds of exceptional quality with minimal heat input, low levels of distortion and is widely used in automotive, aerospace, aeroengine and other industries.

- Game-changing in its approach, Ebflow™ is a local vacuum electron beam welding system that can be used to join significantly larger components than an in-chamber welder can accommodate. Ebflow™ is up to thirty times faster than conventional welding techniques and can weld 250mm thick steel in a single pass – enabling the fastest thick-section rates ever. Suitable for welding steel structures of large size, the technology is particularly popular in the production of pressure vessels for oil and gas, nuclear, and renewable energy applications such as monopiles for wind turbines.

- Evflow™ is an electron beam welding system for producing electric vehicles (EV). As demand for EVs increases, battery manufacturers are under pressure to make power packs faster to support the transition to a low-carbon economy. Evflow™ can support this drive, producing strong, high-quality welds for batteries, stators, shunts, and power train components.

- Laser Welding in Vacuum enables high quality welds to be produced up to three times the depth and with much less weld spatter compared to conventional laser welding.

Steve Horrex, Sales Director at CVE, said: “The past few years have seen manufacturers come under increasing inflationary pressures. Rising raw material costs and energy prices have taken their toll on profits plus there have been significant supply chain and labour shortages. For manufacturers looking to get costs under control, electron beam and laser welding technologies provide a clear way to work more efficiently and increase output. Since the last Schweißen & Schneiden, demand for our Ebflow™ and Evflow™ technologies has increased - particularly in energy applications and the automotive industry. After several years absence due to COVID, we’re excited that Schweißen & Schneiden is back and look forward to bringing event attendees up to speed with the latest CVE news.”

CVE has more than sixty years’ experience supplying electron beam and laser welding systems that can save customers time and money – while also improving the quality of welds. Depending on the application, machines can be built to individual customer requirements with the business able to provide a turnkey solution plus after sales support that is second to none.

For more information, visit CVE at Schweißen and Schneiden in Hall 3 at Stand 3B51.

Alternatively, email: sales@camvaceng.com

(Source: Press release of Cambridge Vacuum Engineering)

Schlagworte

Electric VehiklesElectron Beam WeldingLaser WeldingManufacturingWelding