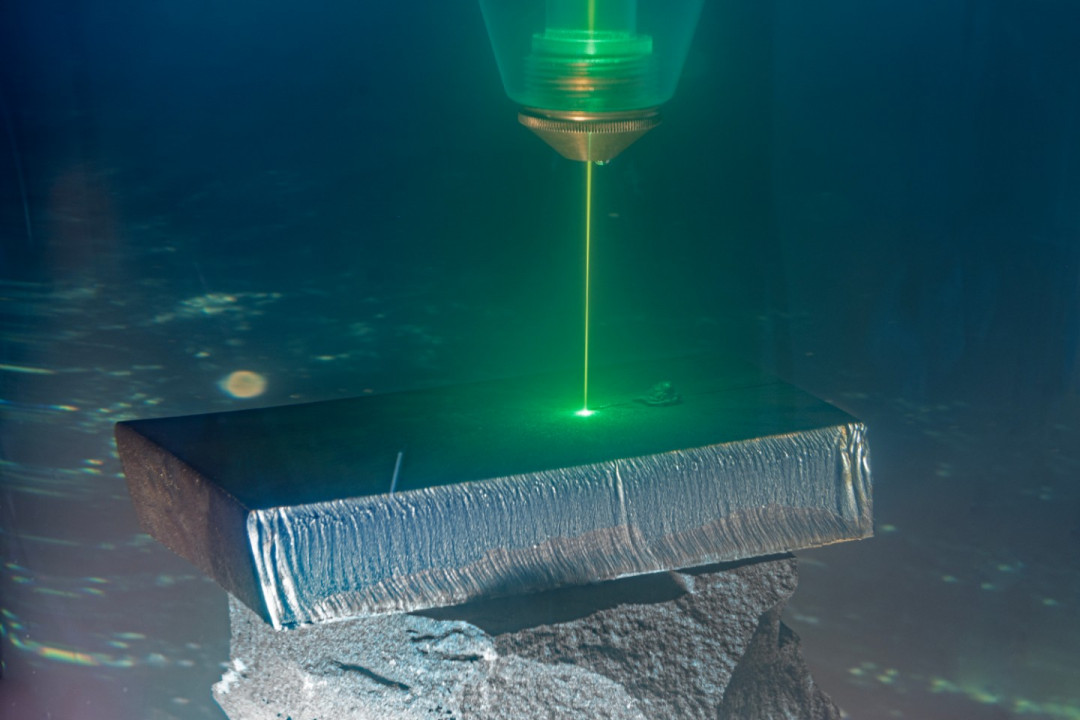

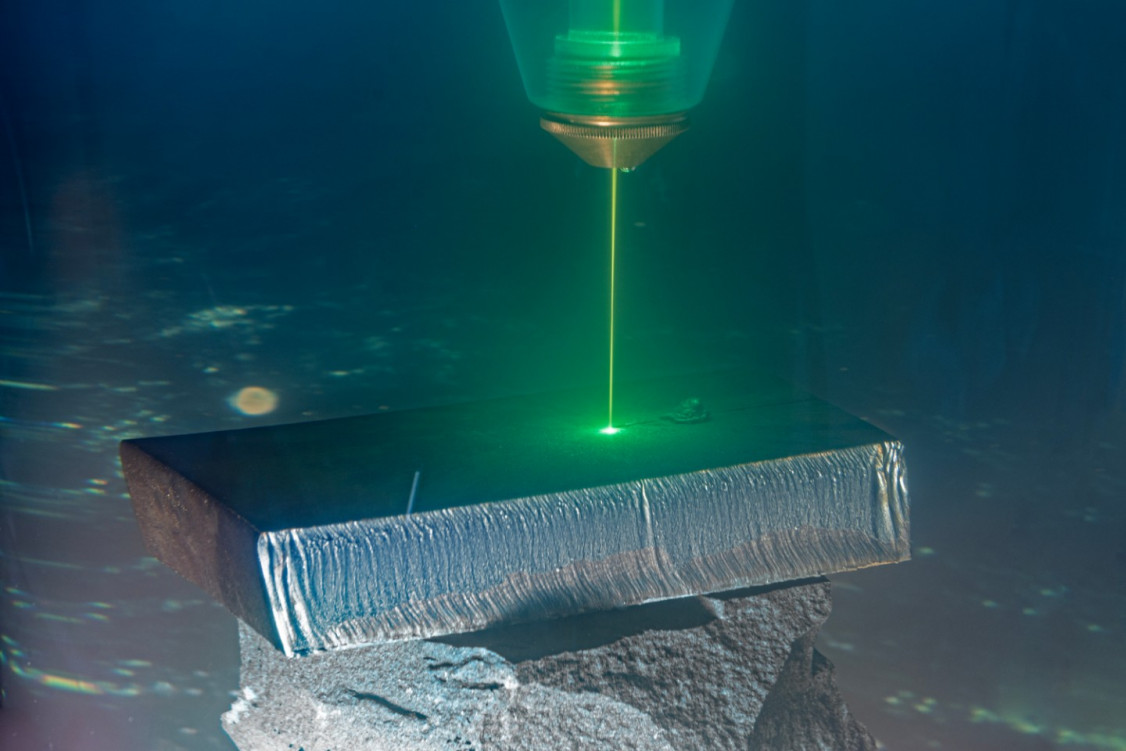

Laser cutting under water

Given the increasing demand for renewable energy sources, the need for modern dismantling technologies for underwater use is also growing. For example, to bring a wind power plant in the sea up to more power, old steel frames must first be dismantled below sea level to rebuild them later in a larger size. The Fraunhofer Institute for Material and Beam Technology IWS in Dresden has now found a technological approach to use lasers as particularly efficient, environmentally friendly, and energy-saving cutting tools in water.

To cut steel and other metals below the water surface, the Fraunhofer researchers use particularly short-wavelength green lasers with the ability to cut even in water. At the same time, the water serves as a tool to expel the resulting melt from the kerf with pressure. This eliminates power losses, extra gas lines, and other disadvantages. In the laboratory, this already works. In September, Fraunhofer IWS will present the innovative process at the SCHWEISSEN & SCHNEIDEN trade show in Essen to advance it to application maturity together with industrial partners. Cutting metal with lasers is not a fundamentally new approach. However, it usually occurs in a dry environment. Infrared or other rather long-wave laser radiation cuts the metal. Coaxially with the beam, auxiliary gases remove the molten metal in the process. Different conditions prevail in the sea: Water scatters long-wave light in all directions. As a result, a large part of the laser power dissipates after a short distance. Complex piping systems are also required for the auxiliary gas.

Kilowatt-class Green Lasers as Key to Underwater Cutting

These disadvantages are eliminated with the new solution provided by Fraunhofer IWS. The Dresden engineers use green lasers with much shorter wavelengths than most industrial lasers today. However, this is only possible since green lasers in the more than one kilowatt class have become available to achieve the necessary cutting power. In the future, shorter-wavelength versions with blue lasers are conceivable. Such short -wave lasers penetrate even water without significant losses and can thus also be used in bodies of water. This medium abundantly available in the sea can replace the cutting gas required in a dry environment: This eliminates the need for gas pipelines. As a further advantage, gases and gas mixtures such as air can be compressed to a certain point before they are used in the actual application. Water, on the other hand, can hardly be compressed. Therefore, as a cutting medium, it removes the melt residue at the interface with less force and loss of time.

Less Energy Loss and More Power

Compared to today's common cutting methods with saws, automatic saw wires, and plasma cutters, underwater laser cutting is expected to achieve several advantages: “The process requires comparatively little energy, and the power transmission is more efficient,” emphasizes project leader Dr. Patrick Herwig, who heads the Laser Cutting Group at Fraunhofer IWS. He adds that this approach also allows the construction of particularly compact underwater robots with laser attachments. Because these could be implemented smaller and more efficiently than the automatic sawing machines of today, previously difficult-to-access areas of underwater structures can be reached more easily. Unlike sawing, for example, dismantling teams would not need to continuously load future cutting lasers with new blades or other supplies. In addition, such a system does not generate waste or release hazardous materials into the atmosphere. This advantage is particularly important when demolishing old nuclear power plants. There, too, steel components often have to be dismantled underwater first. If cutting gas was used here, radioactive waste could reach the water surface with the bubbles. Laser underwater cutting eliminates this problem as well.

Water: Friend instead of Foe

Prof. Christoph Leyens, Director of Fraunhofer IWS, describes the economic and social relevance of the innovative technology: “70 percent of the earth consists of water. In the future, humanity must increasingly use these offshore reserves to develop and expand environmentally friendly energy sources. We need new underwater manufacturing technologies like our laser cutting solutions. Until now, water has been seen as the ‘enemy’. We are reversing that and understanding it as a ‘friend’.” In the next step, the researchers want to further develop their lab-scale proven concept into practically applicable systems. Fraunhofer IWS contributes its expertise in laser technology, system and analysis technology, and the design of complete systems. The scientists are currently looking for industrial partners to outline concrete application scenarios, experiences, and challenges as well as to accompany the substantial technology development.

For networking purposes, the research team will present underwater laser cutting from September 11 to 15, 2023, at the SCHWEISSEN & SCHNEIDEN in Hall 6, Booth 6D29.

Schlagworte

CuttingDismantlingLaserMetalSteelUnderwater Technology