Often misjudged: Welding with alternating current

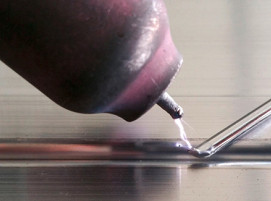

Welding with alternating current (AC) is often underestimated in arc welding. However, it offers clear advantages wherever welding with direct current (DC) reaches its limits. Especially in demanding applications such as aluminum welding. The combination of positive and negative half-wave makes it possible to break through the oxide layer of the aluminum and at the same time control the heat input. This is particularly advantageous with thin aluminum sheets, where controlled penetration and the lowest possible heat input contribute between success and failure.

Focus on precision and efficiency

Compared to the DC process, the AC process enables improved gap-bridging capability, a higher welding speed, reduces the development of fumes and prevents the effect of magnetic forces on the arc – the so-called arc blow phenomenon.

With a suitable welding power source such as the iROB power source series from Abicor Binzel, AC welding is raised to a new level. The iROB 401 AC/DC welding power source offers an excellent solution for welding with alternating current. The typical fields of application are sheet thicknesses close to 1.5 mm. The result is MIG/MAG weld seams with a TIG appearance.

AC welding deserves more attention

AC welding offers clear advantages in terms of precision, efficiency and material protection. With the iROB 401 AC/DC power sources from Abicor Binzel, AC welding is becoming an attractive option for demanding welding tasks. It is time to fully exploit the potential of alternating current.

Read more about the advantages of welding with alternating current here:

Further information on the iROB welding power source can be found here:

(Source: Press Release Alexander Binzel Schweisstechnik GmbH & Co. KG)

Schlagworte

Alternating CurrentAluminium WeldingDirect Current