Residual stresses and defects in modern welding and additive manufacturing

With the advent of greater demand for online training, HERA, IIW India, SAIW and the CWB Association are cooperating and collaborating to transfer the knowledge and experience of world experts into as many countries on a global basis.

The four organizations will arrange for webinars and eCourses to be presented by such world experts to meet the challenges of different time zones, the need to assist individuals and industries to optimize their training times as well as improve their national welding capabilities.

This presentation is brought to you by: Prof Anna Paradowska, Industry Engagement Manager (since 2014) at the Australian Centre for Neutron Scattering (ACNS), Australian Nuclear Science and Technology Organization (ANSTO) as well as Conjoint Professor in Advanced Structure Materials (since 2019) at The University of Sydney.

This presentation will focus on the challenges and highlights of residual stress and defect assessment using several portable and nonportable techniques for welding and additive manufacturing components.

- Welding, cladding and repairs in civil, energy mining and transport applications.

- Additive manufacturing and composites for small and large-scale applications

- Non-destructive and destructive residual stress and defects assessment for fitness for purpose

Where and when:

The WEBINAR will be of one and a half hours duration including half an hour for questions and discussion. It will be held on four separate occasions to accommodate the four different regions of the globe: The Americas; Africa and Europe; Indian sub-continent; Asia and Australasia.

Who should attend?

Designers, structural engineers, consultant engineers, mechanical engineers, welding and production engineers, maintenance and quality control engineers, as well as researchers. Delegates are encouraged to bring along their problems to contribute to discussions and local case studies.

What industry areas the webinar is relevant for?

The WEBINAR will be especially relevant to all professionals in automotive, aerospace, steel construction,

steel bridge design, power generation, naval and shipbuilding, offshore construction, pipeline and other

industries that apply welding and additive manufacturing.

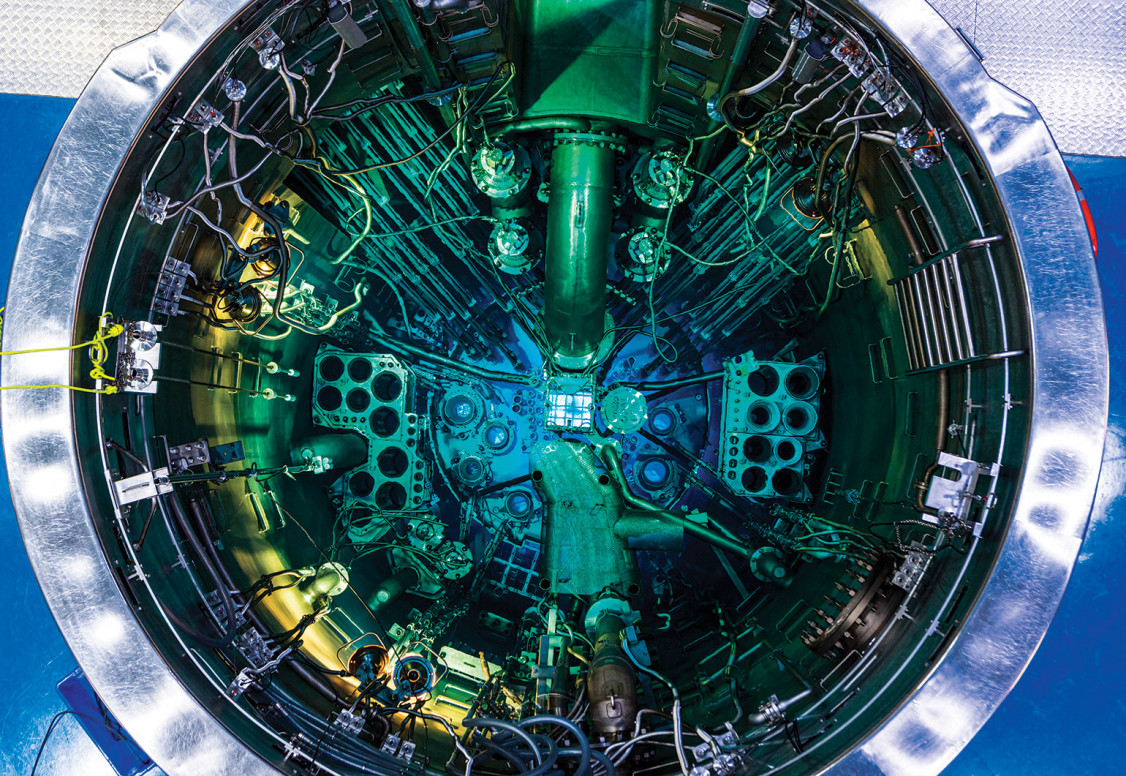

The OPAL Research Reactor at ANSTO

Australian OPAL research reactor at ANSTO has several instruments available for materials science and engineering applications. The instruments have a unique non-destructive ability to determine critical imperfections, assist performance of engineering apparatus via radiography and tomography, measure internal residual stresses and textures in crystalline

materials, such as metals, alloys, ceramics, and composites.

These measurements can be carried out on real engineering components, mock-ups, or test samples with minimal preparation. This information provides direct impact into optimization of modern manufacturing processes, improved product reliability, enhanced design performance, reduced production cost, and extended life prediction on significant engineering assets.

The versatile team at ANSTO has established a strong record in assisting Australian and international researchers and engineers across a wide range of engineering projects. The newly developed Australian Stress Engineering and the Solid-State Manufacturing Centres, and a Node of Sovereign Manufacturing Automation for Composite (SoMAC CRC) at the University of Sydney are building on this experience and collaboration. Support and advice is available to industry as well as academia on manufacturing, characterization and assessments of welding, additive manufacturing and composites.