Additive manufacturing: BAM research at the Werner-von-Siemens Center enters second phase

The Federal Institute for Materials Research and Testing (BAM) is continuing its research projects on highly efficient gas turbines at the Werner-von-Siemens Centre for Industry and Science e.V. (WvSC) for another two years. The projects, which are funded by the state of Berlin and the European Union, aim to optimize the maintenance, repair and development process of gas turbine blades and to develop sustainable additive manufacturing solutions.

Gas turbines play a crucial role in energy generation. Their efficiency and sustainability are of great importance because if less fuel is needed to generate the same amount of energy, greenhouse gas emissions are reduced. Current challenges, such as the wear of turbine blades due to corrosion and harsh operating conditions, require innovative solutions. The projects aim to use state-of-the-art additive manufacturing processes and digital solutions to increase productivity and performance in gas turbine construction, increase material reusability and exploit previously untapped potential.

MRO 2.0: focus on human-machine interaction and AI

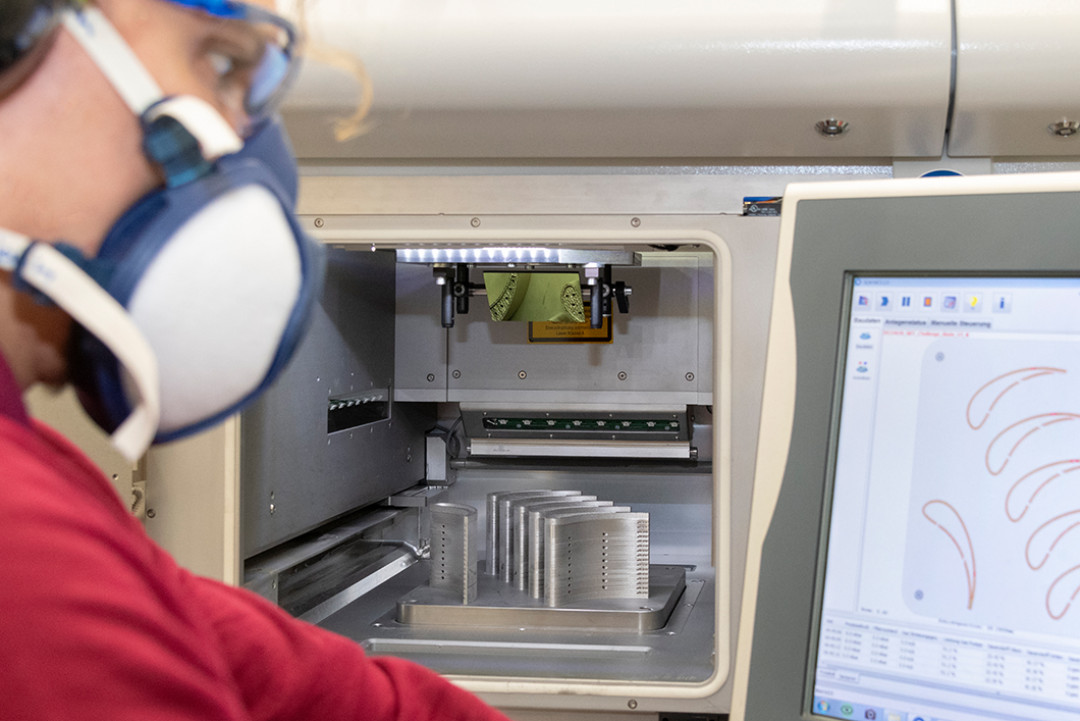

The MRO 2.0 project focuses on optimizing the repair process for gas turbine blades. The team is developing automated and digitalized refurbishment process chains that enable upgrades for highly efficient gas turbines. The goal is to automate and digitalize the repair process for turbine blades. While demonstrators and systems for assessing the condition of turbine blades as well as additive repair processes were developed in the first project phase, the focus of the second project phase is on transferring the findings to deployment. In addition to the technical issues, aspects of occupational psychology, such as the acceptance of new workflows and processes, will also be examined.

In the project, the BAM team is focussing primarily on new test methods for determining the residual wall thickness and assessing near-surface damage. They make it possible to precisely analyze the condition of the used turbine blades in order initiate suitable repair steps. Additive manufacturing technologies are used for the repairs. BAM develops, evaluates and qualifies suitable processes such as wire arc additive manufacturing, in which additional material is applied in a targeted manner, for example to replace material removed during operation.

The scientists are also developing virtual models, known as digital twins, of the entire process. With the help of AI algorithms, they continuously analyze data on the operating conditions and the behavior of the turbine blades in use. This enables them to make predictions about the remaining service life of components, proactively plan maintenance measures and minimize downtimes. Ten partners are involved in the project, including Siemens Energy, several Fraunhofer Institutes and the Technical University of Berlin.

HTA 2.0: Sustainable additive manufacturing for high-temperature applications

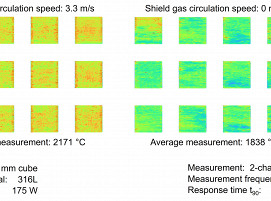

The HTA 2.0 project is developing sustainable additive manufacturing processes and components for high-temperature parts in large gas turbines. It builds on the successful results of the first funding period, in which the processing of high-temperature materials for complex components was characterized using powder bed-based laser beam melting and effective process monitoring techniques were developed. This will enable component defects to be detected during the process in future.

In the current project, the focus is on faster and more efficient processes. The additive manufacturing processes are evaluated in the context of sustainable product development in order to achieve more economically and ecologically efficient component solutions for the area of high operating temperatures in gas turbines. For example, various post-processing methods for additively manufactured components are investigated and automated as far as possible in order to replace the manual and time-consuming processing steps that are still required today.

A central research focus is on increasing the reusability of the starting material for additive processes and reducing material waste. To this end, recycling strategies are developed and tested for both used powder and consolidated solid material from waste originating from faulty construction processes and support structures. That way high material costs and environmental pollution are reduced. Holistic life cycle analyses evaluate the economic and ecological effects.

The project includes eleven partners from scientific institutions, large corporations and several SMEs. BAM is contributing its expertise in comprehensive material characterization, the additive manufacturing process, process monitoring and component inspection as well as the determination of material behaviour at high temperatures.

(Source: BAM Press Release)