Best Award for High-resolution Printing of Lubricants

The precise application of oil-free lubricants with the REA JET HR-Lube system brings "the best of two worlds together", says Dr. Philipp Hedrich, Head of Product Management at REA JET. On the first day of Blechexpo 2023, the innovation was awarded second place in the Best Award in the Stamping Technology category.

"We are very pleased about the award because it recognizes our search for new and, above all, sustainable application possibilities for our printing technologies," said Hedrich about the award, which Tobias Götz, Project Engineer at REA JET, and Johannes Lülsdorf, Managing Director of LBI oil free, received for the cooperation project. As prize winners, they also had the opportunity to present the innovationat the Blechexpo exhibitor forum.

The best of both worlds: Cartridge technology and oil-free lubricants

Cartridge technology, which has been tried and tested for years, gives users great process security; with oil-free lubricants, automatic punching and bending machines remain clean. REA Elektronik and LBI oil free combined their many years of expertise in these areas and developed a joint application that allows sheet metal manufacturers to become more efficient and sustainable and also reduce their costs. The REA JET HR-Lube system applies the lubricants mist-free and precisely where they are needed - with an application width of up to 12.7 millimeters per cartridge print head and the option of cascading up to eight print heads for a precise application more than 100 millimeters wide. As the lubricants are oil-free, the punched parts themselves do not need to be washed and can be processed immediately. The mist- and aerosol-free, precise application with the digitally controlled nozzles of the REA JET HR eliminates the need for any suction and prevents dripping, which saves further cleaning steps and machine downtimes. Thanks to the precise dosing, the manufacturing costs per component can also be calculated more precisely.

The best of both worlds: Cartridge technology and oil-free lubricants

Cartridge technology, which has been tried and tested for years, gives users great process security; with oil-free lubricants, automatic punching and bending machines remain clean. REA Elektronik and LBI oil free combined their many years of expertise in these areas and developed a joint application that allows sheet metal manufacturers to become more efficient and sustainable and also reduce their costs. The REA JET HR-Lube system applies the lubricants mist-free and precisely where they are needed - with an application width of up to 12.7 millimeters per cartridge print head and the option of cascading up to eight print heads for a precise application more than 100 millimeters wide. As the lubricants are oil-free, the punched parts themselves do not need to be washed and can be processed immediately. The mist- and aerosol-free, precise application with the digitally controlled nozzles of the REA JET HR eliminates the need for any suction and prevents dripping, which saves further cleaning steps and machine downtimes. Thanks to the precise dosing, the manufacturing costs per component can also be calculated more precisely.

Integration into production via state-of-the-art interfaces

The system is especially suitable for the production of electronic components, for example in cell phone production, contact plugs, mechanical watches or other small mechanical parts. This is where another advantage of the cooperation comes into play: thanks to state-of-the-art interfaces, the digital printing systems from REA Elektronik can communicate with higher-level control systems and integrate seamlessly into production - in line with Industry 4.0.

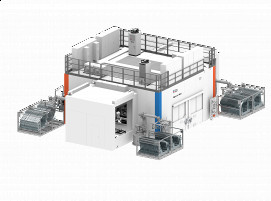

The two project partners have also developed a solution for coil and blank wetting with application widths of up to 2,300 millimetres: The REA JET DOD-Lube system, based on large character inkjet printer technology, also enables the mist-free, drip-free, precise application of LBI oil free's high-tech lubricants. "All systems can be optimally designed for individual applications in cooperation with the customer," says Dr. Philipp Hedrich. "And not just for the award-winning technology for stamping applications - but for all industrial processes in which lubrication is required or other fluids need to be applied."

(Source: REA JET Press Release)