On Thursday, November 20, 2025, Nord Rhine-Westfalia's Minister-President Hendrik Wüst will officially open Greenlyte’s new carbon capture plant and deliver a welcoming address. The innovative facility filters CO2 from the air and, using renewable energy and hydrogen, produces synthetic, climate-neutral fuels. The company successfully participated in the state government’s funding competition Produktives.NRW and will receive EU funds worth millions to support the construction of new production facilities.

Avoiding CO2 emissions is a global goal in the fight against climate change. To achieve this, e-mobility, hydrogen fuel cells and many other technologies are being employed. There are still numerous industrial processes where a full switch to renewable electricity or hydrogen is difficult – and cannot be entirely avoided. One idea that promises a solution is Direct Air Capture (DAC).

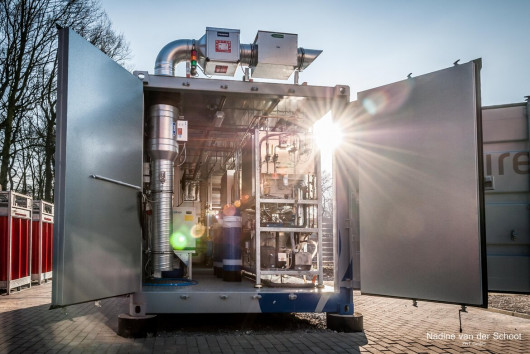

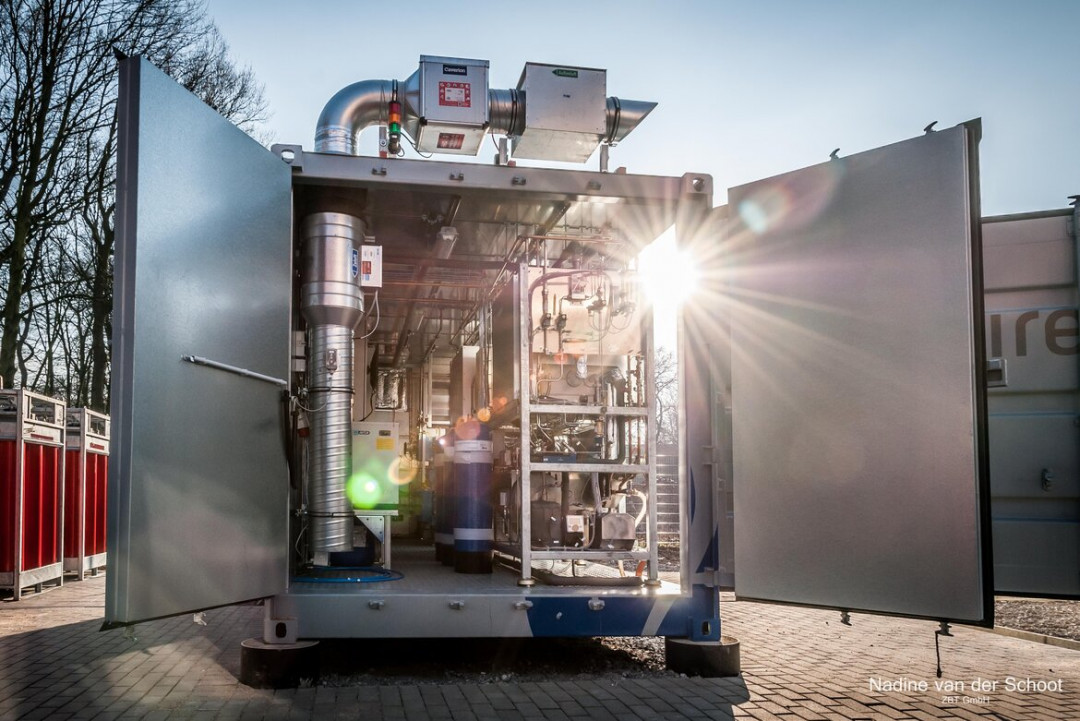

The company was founded in 2022 as a spin-off of the University of Duisburg-Essen, Germany. The underlying process has also convinced investors. "[...] We commissioned a demonstration plant here in Essen with an absorption capacity of 100 t of CO2 per year – that’s equivalent to the annual growth of 10,000 trees. Now we are combining all process steps from CO2 capture to preparation for industrial use in a fully automated prototype."

From an ecological perspective, natural methods remain a primary focus for binding CO2 from the atmosphere, such as rewetting peatlands or creating forests. Yet DAC technology can meaningfully complement these approaches. Greenlyte is not alone in this field: Schmickler estimates that the global DAC community includes around 100 companies, pursuing very different technologies – some still in the idea stage, others already in large-scale application. What makes Greenlyte’s approach special is not the idea itself but its optimal implementation. "In the long term, we are more than twice as efficient as the conventional processes on the market," says the industrial engineer, "and there are three reasons for this: our process requires no high temperatures, it is decouplable and it produces hydrogen as a by-product."

Patented process – promising technology

The overall DAC process has two main stages: absorption and desorption. During absorption, CO2 is captured from the air by a special substance called absorbent. During desorption, the CO2 is separated from the absorbent to either be used as a raw material or stored permanently underground. Greenlyte’s DAC process is based on a liquid absorbent and represents the current state of the art. "The process is patented and the result of 15 years of research. Technologically, I see our method as the most promising approach to drastically reduce the costs of CO2 capture – costs that are crucial for industrial implementation."

To extract CO2 from the air, it must be brought into contact with the absorbent. Greenlyte accomplishes this at ambient temperature in a so-called gas scrubber – a type of tower in which the liquid absorbent flows downward through a special structure. The design of this structure, called packing in technical terminology, is crucial to achieve maximum distribution and surface area. It is at this surface that the absorbent reacts with CO2 from air, which is continuously blown upward in counterflow through the scrubber. As a result, crystals of potassium bicarbonate form – a salt found in mineral water and used as a leavening agent for gingerbread. This compound contains chemically bound CO2.

Advantage through renewable energy and hydrogen

Absorption according to this principle requires little energy; essentially, air must only be blown through the scrubber and the absorbent pumped – enough to “wash” CO2 from the atmosphere around the clock. Desorption, on the other hand, is carried out via electrolysis at Greenlyte and requires comparatively more electricity. Here, another property of bicarbonate proves advantageous: it is storable. This makes the process decouplable, meaning electrolysis can be carried out only when sufficient green electricity is available, for example, from wind or solar energy.

A further, potentially decisive advantage involves a highly sought-after energy carrier: hydrogen. Green hydrogen is used to make energy-intensive processes, such as steel production, climate-neutral. A good way to produce green hydrogen is through water electrolysis using renewable energy. Adding bicarbonate to the water generates CO2 alongside hydrogen, an effect Greenlyte leverages. The CO2 desorption occurs almost “piggyback,” while hydrogen is simultaneously produced. "Green hydrogen is highly in demand, can be sold and in combination with desorbed CO2, can also be used to produce e-fuels and other hydrocarbons. In our process, it is a by-product, which makes it particularly economical," Schmickler says.

From NRW to the world – business model and opportunities

Plants of various sizes are planned for global deployment. Schmickler also sees a potential business model for numerous specialized companies in the Ruhr region: "We believe DAC technologies based on German engineering could become the next export hit. Here in NRW, there are already many companies with the relevant know-how." Schmickler does not see traditional industrial and plant engineering companies as competitors; instead, he sees new business opportunities. "To achieve international climate goals, even with ambitious climate protection, emissions must be removed from the atmosphere. By 2050, that will amount to around 10 gigatons annually, according to projections. There is plenty of work for the DAC community."

(Source: Ministry for Environment, Nature Conservation and Transport / State Government of North Rhine-Westphalia)

Schlagworte

Carbon CaptureCCSCO2E-MobilityEUEuropean UnionHydrogenManufacturingNord Rhein-WestfaliaNRWRenewable EnergySteelSustainability