Manufacturing and machining processes have evolved dramatically over the decades. One of the most transformative developments in recent years is the rise of high-speed machining (HSM). For those new to the concept, high-speed machining may seem like a technical buzzword. However, its practical applications and benefits are anything but trivial, particularly for industries that rely on precision and efficiency to be competitive.

What Is High-Speed Machining?

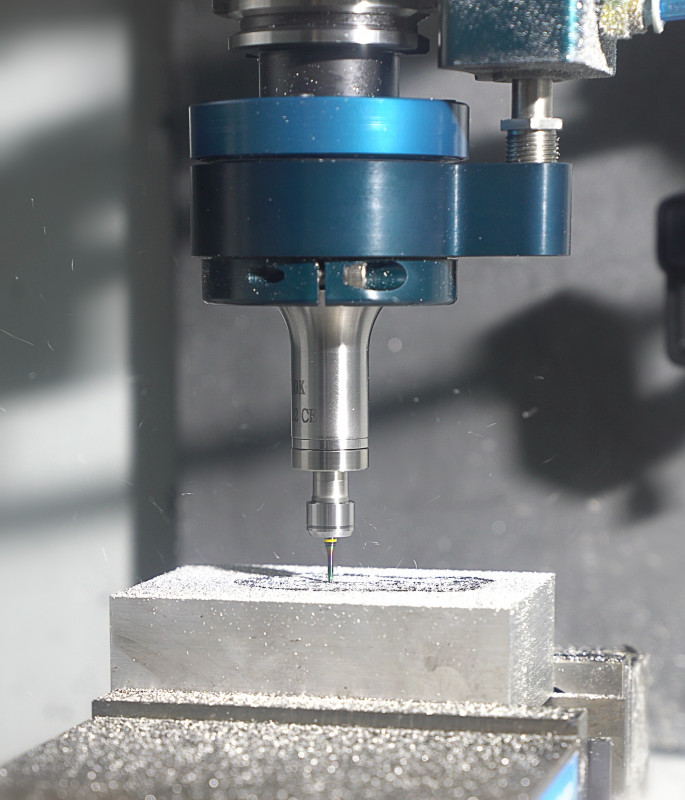

At its core, high-speed machining refers to the process of using smaller cutting tools at significantly higher spindle speeds than conventional machining. Traditional machining typically uses larger tools operating at speeds of up to 20,000 RPM and focuses on heavy material removal. In contrast, HSM can reach spindle speeds of 40,000 to 90,000 RPM or more, enabling finer, more precise work with micro tools. High-speed machining is essential for applications requiring intricate detail or micron-level precision. For example, when machining small parts or intricate geometries, conventional spindles are too slow to effectively work with small tools and tie up the machine for extended periods. HSM fills this gap by enabling these tools to operate at the necessary speeds while maintaining accuracy and reducing operating costs.

Benefits of high-speed machining

The advantages of high-speed machining are multifaceted, impacting everything from productivity and surface quality to tool life and operational costs. One of the most compelling reasons to adopt high-speed machining is the exponential reduction in cycle times. Machining at speeds of 50,000 RPM or higher can reduce cycle times by six to ten times compared to conventional methods. This means parts are produced faster, machines are freed up sooner and overall productivity skyrockets.

In one case study, a high-speed spindle reduced machining time by 100 % compared to a standard CNC spindle. High-speed machining excels at delivering fine surface finishes and micron-level accuracy. By using light, layered cuts and higher surface feet per minute (SFM), HSM minimizes vibration and heat generation, ensuring finer, more consistent finishes. HSM is suitable for industries like aerospace, medical devices and jewelry, where surface quality is critical.

High-speed machining enhances tool lifespan by maintaining consistent spindle speeds under load. Tools are less likely to break due to speed drops, a common issue in conventional setups. Additionally, the heat generated during cutting is left behind, further preserving the integrity of the tools. Plus, HSM is suitable for a wide range of materials, from titanium and aluminium to composites, plastics and even ceramics.

Common misconceptions about high-speed machining

Despite its advantages, high-speed machining is often misunderstood. Some of the most common misconceptions are:

- Air Tools Lack Power: Historically, air tools were seen as underpowered, particularly when compared to electric spindles. However, advancements have shattered this notion by combining high speed with high power, ensuring reliable performance in cut at high speed.

- High-Speed Spindles Are Unreliable: Traditional high-speed spindles, such as electro spindles or coolant spindles, often suffer from issues like overheating, thermal expansion, burnout, clogging with chips and frequent breakdowns. Modern solutions mitigate these concerns by eliminating heat generation and using direct-drive, compressed air-powered technology, with only two moving parts.

- High-Speed Machining Is Only for Small Tools: While HSM is particularly effective with micro tools, its benefits extend to a variety of applications, including machining molds, deburring, contouring and cutting complex geometries in materials including graphite, fiberglass, acrylic and even glass lenses.

- Practical Advice for Implementing High-Speed Machining: For manufacturers considering high-speed machining, here are some key factors to keep in mind:

- Optimize Programming

High-speed machining requires specific programming techniques to maximize its benefits. Focus on using high advance rates and light, layered cuts. For drilling, consider pecking cycles to minimize heat buildup and extend tool life. - Balanced Cutting Tools

Ensure your cutting tools are balanced and have the appropriate number of flutes. Tools with four to six flutes are ideal for reducing load per tooth, evacuating chips quickly and minimizing heat generation. - Use Proper Speeds and Feeds

Calculate optimal speeds, feeds, and horsepower requirements using the machinist’s handbook or specialized software. Start with a light pass adjusting feed rates to achieve the desired chip load and surface finish. - Choose Reliable Spindles

Invest in high-speed spindles and live tools that maintain consistent fixed speed under load. Avoid older technologies like vane motors or ungoverned turbines, which are prone to speed drops and tool wear and breakage.

Air Turbine Spindles maintain high speed (up to 90,000 RPM) thanks to technology that increases airflow volume to match cutting loads. This ensures consistent performance, even in angles on the toolpath. Unlike electro spindles which generate heat and require cooling periods, Air Turbine Spindles operate continuously without generating heat and without thermal expansion. Powered by compressed air (90 psi / 6.2 bar), Air Turbine Tools require no wiring, control boxes or lubrication systems. Set-up is quick and simple. Another advancement is with only two moving parts, these spindles are highly durable and virtually maintenance-free.

(Source: Mike Blanchard, Technical Advisor at Air Turbine Tools Inc.)

Schlagworte

AerospaceCNCCuttingMachiningSpindlesToolsWelding