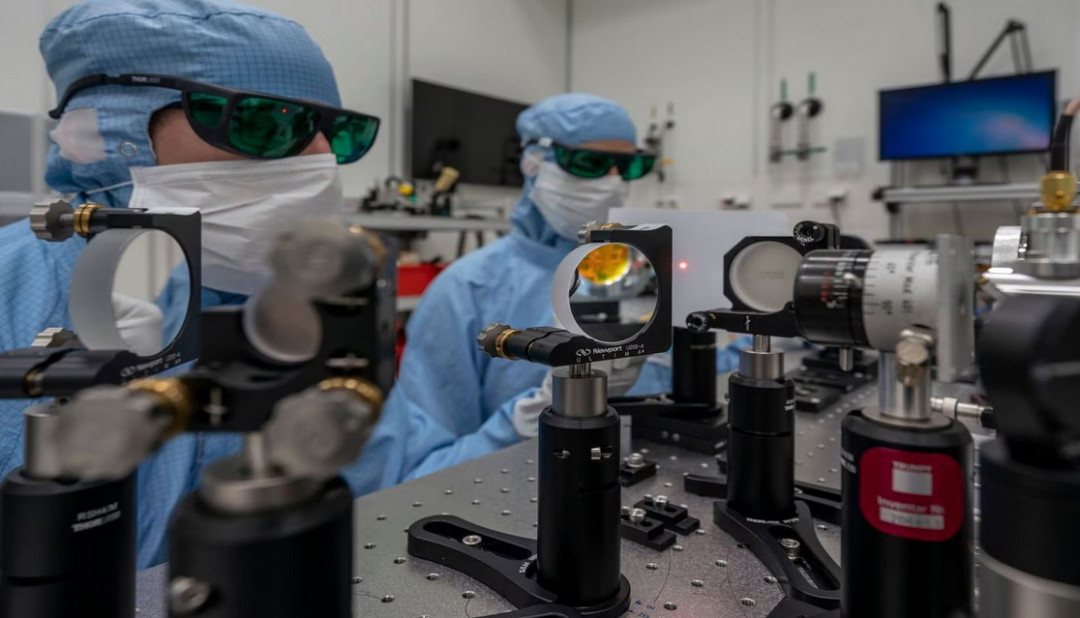

The high-tech company Trumpf, the Fraunhofer Institute for Laser Technology ILT and the Dahlem Center for Complex Quantum Systems at the Department of Physics at Freie Universität Berlin, all Germany, are researching the fundamentals of laser physics with the help of quantum algorithms. The long-term goal is to use quantum computers to significantly accelerate the development process for new lasers in the future. “If we understand the physical processes involved in generating and amplifying laser light more precisely, we will be able to make our products even more efficient and increase their performance in the future,” says Daniel Basilewitsch, who is responsible for the project at Trumpf. The central question is whether quantum computers can simulate the complex quantum mechanical processes that take place in lasers better than the conventional high-performance computers that Trumpf has used to date.

Focus on CO₂ lasers and semiconductor lasers

The project partners are focusing their research on CO₂ lasers and semiconductor lasers. "In addition to their use in data transmission, in sensor technology in smartphones, and in the future in autonomous driving, semiconductor lasers are the backbone of most industrial laser applications, either as a pump source or in direct application. The impact of better prediction of amplification properties using quantum algorithms can be correspondingly large. The goal is to use quantum computers to calculate the quantum mechanical processes in semiconductor lasers," says Prof. Carlo Holly, head of the Data Science and Measurement Technology department at Fraunhofer ILT and head of the RWTH Aachen University Chair of Optical Systems Technology. However, it will still be some time before quantum computers can be widely used in industry. Although the first prototypes already exist, they are currently still unsuitable for complex industrial tasks. “Nevertheless, it is important to build up the expertise today so that quantum computers can be used in industry in the future,” says Basilewitsch.

Project partners contribute their respective expertise

Fraunhofer ILT is a leader in the simulation of semiconductor lasers, while the Dahlem Center for Complex Quantum Systems is a leader in the modeling of molecular collisions. Trumpf is developing the first quantum algorithms and coordinating the project. The German Federal Ministry of Education and Research is funding the project with around 1.8 Mio. Euros as part of its Application-Oriented Quantum Informatics funding programme.

First, the researchers are analyzing existing simulation approaches and testing initial quantum algorithms. "The core of the project is the translation of the physical modeling of the desired and undesired energy transfer processes occurring in the CO₂ laser from classical to quantum computers. A better understanding of these processes will then serve to optimize the laser design,“ explains Prof. Dr. Christiane Koch from the FU Berlin. ”The project is an important step toward making energy-intensive chip production more sustainable, where our CO₂ lasers are used today," says Basilewitsch.

(Source: Trumpf Laser- und Systemtechnik GmbH)

Schlagworte

AutomotiveChipLaserLaser TechnologyQuantum AlgorithmQuantum LaserSemiconductor LasersSustainability