WITT Gas presents an upgrade for existing laser cutting systems: laser gas mixers designed for easy retrofitting. These advanced mixers enable users to unlock the full potential of their laser cutting equipment, delivering faster, more precise cuts while reducing operational costs.

Combining nitrogen and oxygen as cutting gases, WITT’s laser gas mixers harness the advantages of both to significantly enhance cutting quality. Especially for medium and thick sheet metal, these gas mixtures enable fast, precise cuts that are virtually oxide- and burr-free. This leads to increased efficiency, minimized reworking, and lower production costs. The process is suitable for a wide range of materials, including steel, stainless steel, and aluminum.

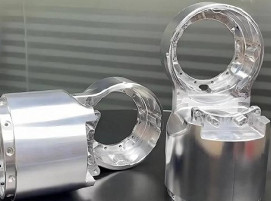

WITT’s laser gas mixers offer a flexible, retrofittable solution for existing laser cutting systems. With infinitely adjustable mixing ratios, users can tailor the gas supply to specific cutting requirements. The laser mixer series delivers a maximum output of up to 438 Nm³/h at inlet pressures up to 40 bar.

Integrated constant pressure control ensures a stable gas supply to the cutting process, even when inlet pressures fluctuate. Advanced mixing technology guarantees consistently high gas quality and is engineered for high-pressure applications.

Retrofitting with a WITT gas mixer is straightforward and compatible with a wide range of laser cutting systems. Depending on the model, operation can be mechanical via a rotary valve or electronic via a touch display. Electronic versions offer multiple interfaces, including Ethernet, RS232, 4-20mA, and OPC-UA, enabling control via external systems and seamless integration into existing production environments.

WITT gas mixers are equipped with a comprehensive range of protective mechanisms and options to ensure reliable operation. Features include inlet pressure monitoring, O₂ gas analysis, temperature monitoring, digital pressure display, as well as memory and acknowledgement functions for maximum transparency and control. Visual and acoustic warning messages alert operators to deviations, and the system can automatically shut down in critical situations to ensure safety

(Source: WITT)

Schlagworte

CuttingEfficiencyGasLaser CuttingMetalRetrofitting