Laser Process Monitoring – Offline, Inline, Online

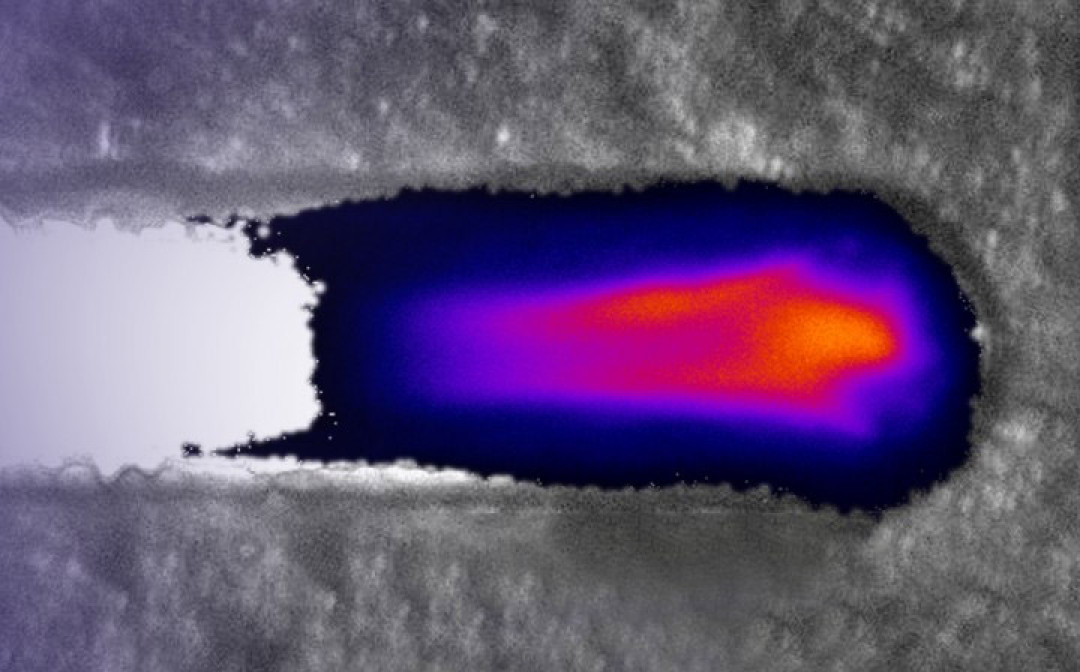

Do you value the laser as a flexible and versatile tool, but wonder how the efficiency and process quality can be optimized even further? One possibility is process monitoring, typically by means of acoustic and optical sensors as well as thermal cameras.

On the one hand, the state of the art is presented, including modern methods of data acquisition and processing, and on the other hand, concrete examples are used to show the possibilities that already exist today for using process monitoring profitably. Burr formation and roughness during cutting and penetration depth and pore formation during welding can be determined. In addition, the possibilities of AI to automate laser processes in the future will be discussed.

Lunch-to-lunch-workshop in Dresden

The advantages that process monitoring offers in laser material processing will be demonstrated by experts together with external partners in the lunch-to-lunch Workshop ”Laser Process Monitoring – Offline, Inline, Online”. Participants will be introduced to the potential of laser process monitoring in lectures and demonstrative laboratory tours.

What does the workshop include?

The workshop will start with insights into the state-of-the-art process monitoring for industrial lasers. You will learn about various optical, acoustic, and thermal methods. In numerous lectures and demonstrations in the laboratory, opportunities and limitations of process monitoring on various laser material processing technologies such as cutting, welding, hardening, structuring and additive manufacturing will be explained. Last but not least the issue of AI approaches to control laser processes in the future will be addressed.

The workshop is aimed at experienced laser users in industry as well as integrators and manufacturers of lasers, optics and system modules. The workshop will be held in English.

For more information on the schedule and to register visit

Fraunhofer IWS Laser Process Monitoring

![SCHWEISSEN & SCHNEIDEN 2025 [EN]](/images/frontend/journals/dvs-sus_sm.png)