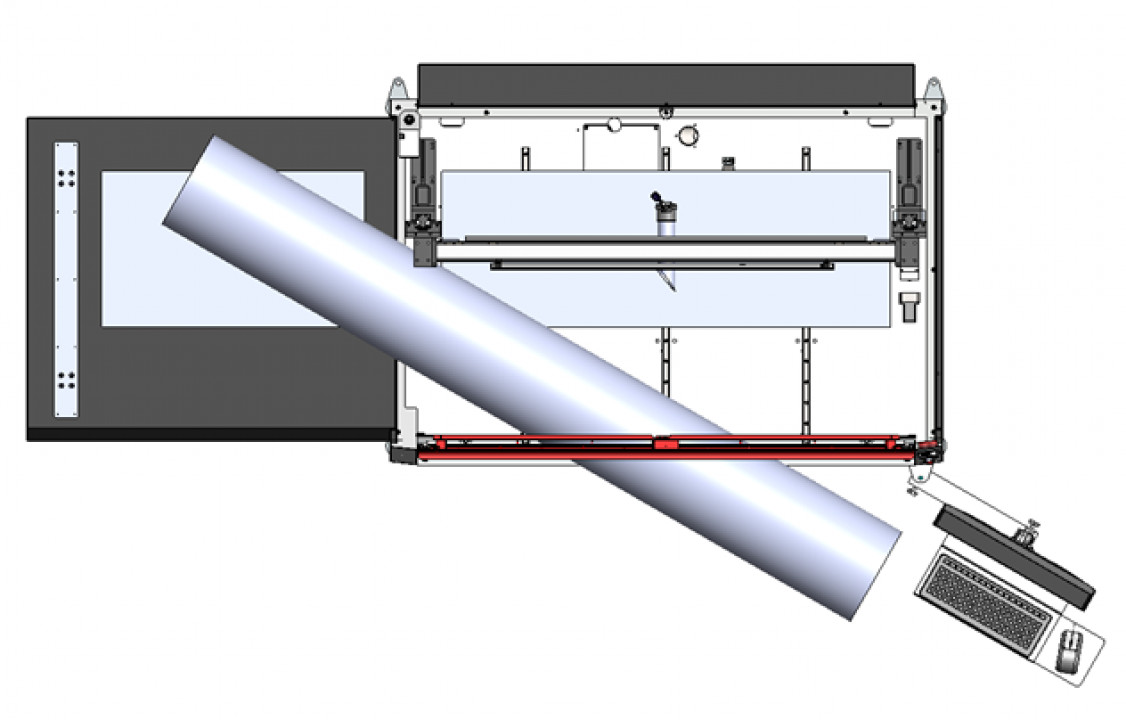

With the SpeedMarker 1600 – long, Trotec presents an individually configured laser system for laser processing of particularly long components. Designed for industrial applications with the highest demands on precision, safety and flexibility, this system processes workpieces up to 2,300 mm in length – and completely in closed operation. Ideal for sectors with large-format components such as the railroad, automotive or aviation industries.

The laser station can be loaded via the front or side door, which facilitates access and speeds up work processes. Magnetic safety switches ensure reliable protection during operation. The combination of Z, X and Y axes, a marking area of 1,000 × 450 mm and a workpiece height of up to 450 mm (at F=160) offers a range of applications – from individual pieces to series production.

Technical highlights:

- Workpiece length: up to 2,300 mm – ideal for oversized components

- Laser power: 20-100 watts – scalable depending on requirements

- Software: SpeedMark – intuitive operation, no training required

- Accessibility: Front and side doors – for efficient placement

Customized instead of standard

Every system from the Trotec laser product portfolio can be tailored to the customer's specific requirements. The Trotec Galvo Competence Center accompanies this entire process – from feasibility analysis and design to commissioning and training.

(Source: Trotec Laser GmbH)

Schlagworte

ApplicationAutomotiveComponentCuttingLaserProcessProcessingWorkpiece