Manufacturers in the plastics industry are under increasing pressure to reduce costs and conserve resources. However, low-cost or recycled plastics present challenges due to their surface structure and composition. Without proper pretreatment, the quality and durability of end products can be significantly compromised. At the international plastics trade fair K 2025 in Düsseldorf, Plasmatreat will demonstrate how to overcome these hurdles. Plasmatreat will present practical solutions using atmospheric pressure plasma. These solutions range from innovative processes, such as in-mold coating with polyurethane (PUR) systems in the automotive industry, to new material combinations for sports applications.

Due to their surface properties, inexpensive and recycled plastics are challenging to process industrially. These surfaces are often more difficult to wet, meaning adhesives, sealants, inks, paints and coatings do not reliably adhere to them. Under these conditions, meeting high demands such as structural bonding, durability and efficiency is difficult. Plasmatreat has been developing systems and equipment for the industrial pretreatment of surfaces using atmospheric pressure plasma for 30 years. Thanks to Openair-Plasma technology, industrial processes can be made more reliable, efficient, and environmentally friendly without the use of chemicals or solvents. At K 2025, Plasmatreat will present application examples to trade visitors, who will be able to experience plasma technology up close.

PUR in-mold coating: plasma improves adhesives

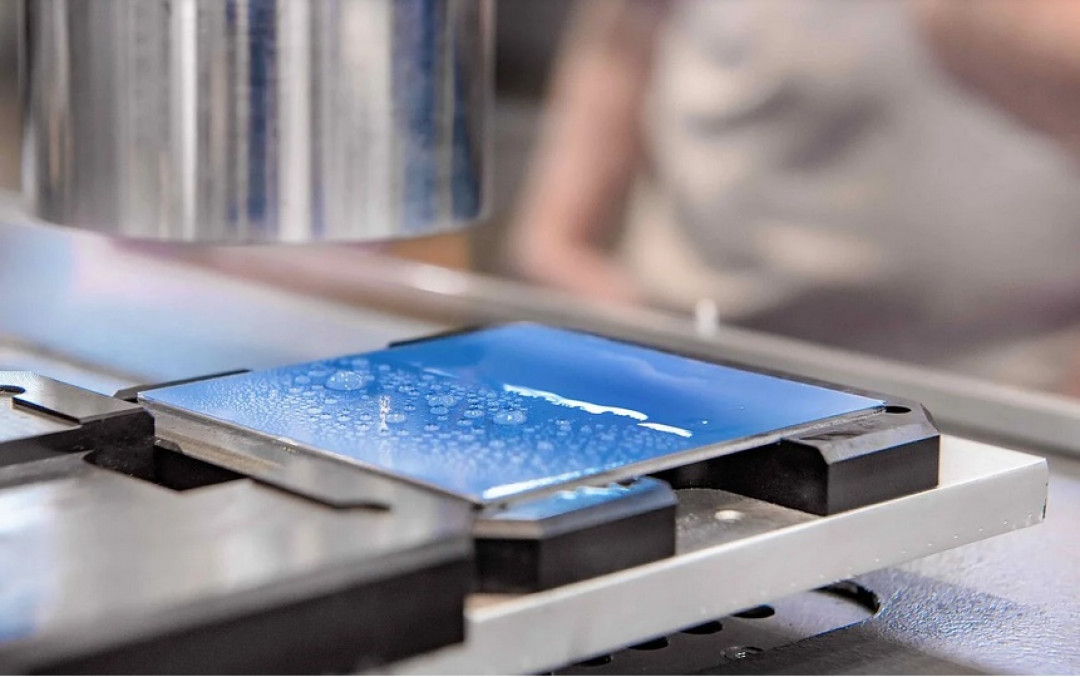

The automotive industry is interested in using standard plastics, such as polypropylene (PP), more frequently instead of engineering plastics, such as PC+ABS. However, the challenge lies in their surface properties. PP is non-polar, meaning the reactive PUR system does not adhere to it. The company is demonstrating how openair-plasma can be used after the injection molding of the PP component and before the PUR in-mold coating process. With the aid of a new, extra-wide, specially developed plasma nozzle, the entire surface of an injection-molded component (e.g., a hood) can be plasma-pretreated in a short time. In addition to physical locking due to surface roughness, the activated PP surface now forms chemical bonds with the reactive PUR coating system. This prepares components for subsequent coating with PUR coating and optimizes the surface according to the required adhesion properties. Openair-plasma is carried out inline, automated and robot-controlled.

Advancing new products and applications

Other possible applications of openair-plasma that can improve industrial processes include pretreating recycled plastics to enable printing with UV inks. Plasmatreat and its partner Tampoprint will demonstrate how to achieve long-lasting, VOC-free printing on dolphins made from recycled plastics, specifically old fishing nets. Additionally, trade visitors will see how plasma activation makes previously incompatible plastic combinations (e.g., PE and PA6, TPU and PP) compatible for bonding. Various tests will also be carried out to demonstrate the effect of plasma treatment.

Visit Plasmatreat at K 2025 from October 8 through 15, 2025, in Hall 11, Booth I65.

(Source: Plasmatreat GmbH)

Schlagworte

AutomotiveCoatingJoining PlasticsPolyurethanePURSurface TreatmentSurfacing