Optimized Arc Reduces Welding Fumes

We all know welding generates harmful fumes. To reduce the welders′ exposure and also improve health and safety at work, process variations and extraction technology need to be considered. Process parameters have a significant effect on the emission rate: Wire speed, arc length and correction parameters significantly influence the level of generated harmful substances. Together with Fronius International, the Aachen Society for Research and Joining Technology (FEF) took a closer look at various parameter settings.

As is evident from the FEF final report of the welding fume studies dated 10/13/2021, the pulsed arc caused the most advantageous material transfer and the lowest fume emission rate (FER) compared to the Low Spatter Control (LSC) arc and the standard arc. More series of tests determined how different welding torch positions, wire speeds and arc length corrections affect the emission rate. Welding was performed with a PMC pulsed arc and the TPS 500i from Fronius.

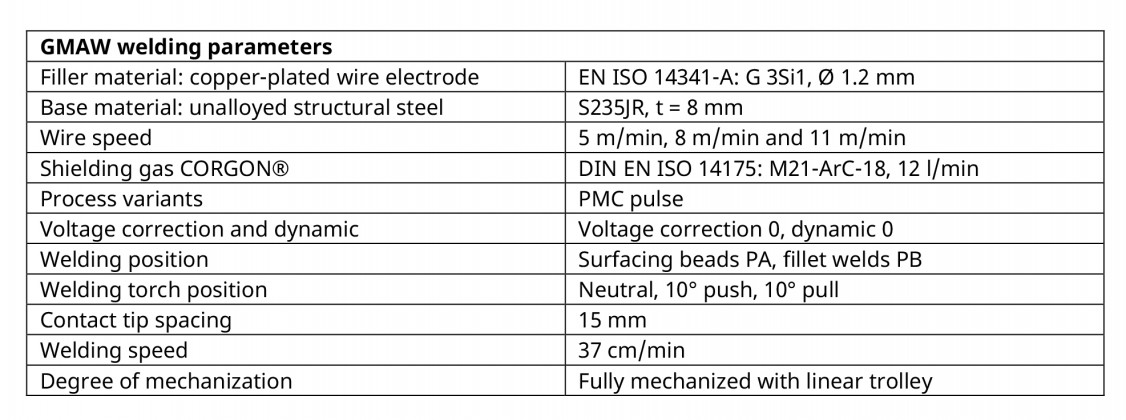

FER when welding surfacing beads

Generally it can be said that welding fume emissions are lowest at 5 m/min wire speed and in neutral welding torch position, where it is apparent that emissions are lower at a wire speed of 11 m/min than at 8 m/min. With the pull torch guidance technique, the emissions are slightly lower at all wire speeds than with the push technique. If welders optimize the arc using arc length correction (with a neutral torch position in the test), the welding fume emissions can be significantly reduced at all wire speeds. Compared to non-optimized arcs, welding fume emissions are slightly lower at 8 m/min with 0.9 mg/s than at 11 m/min with 1.1 mg/s, Fig. 1.

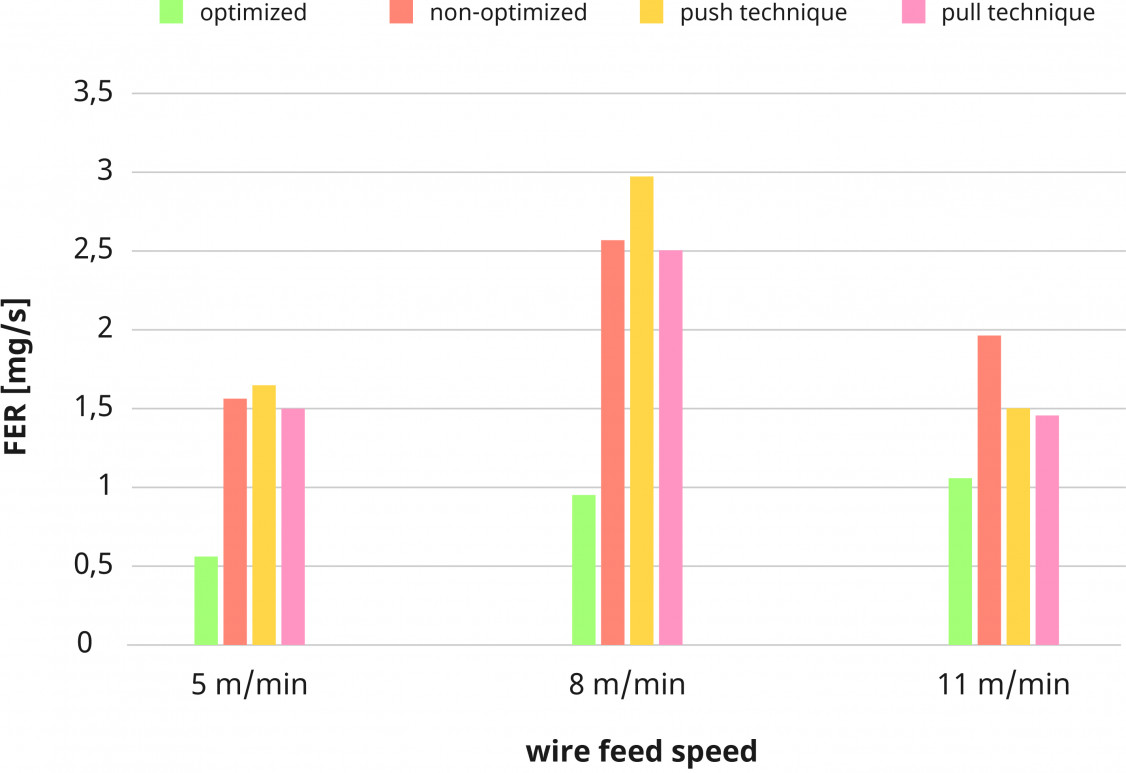

Comparison of the voltage curves with a wire speed of 5 m/min

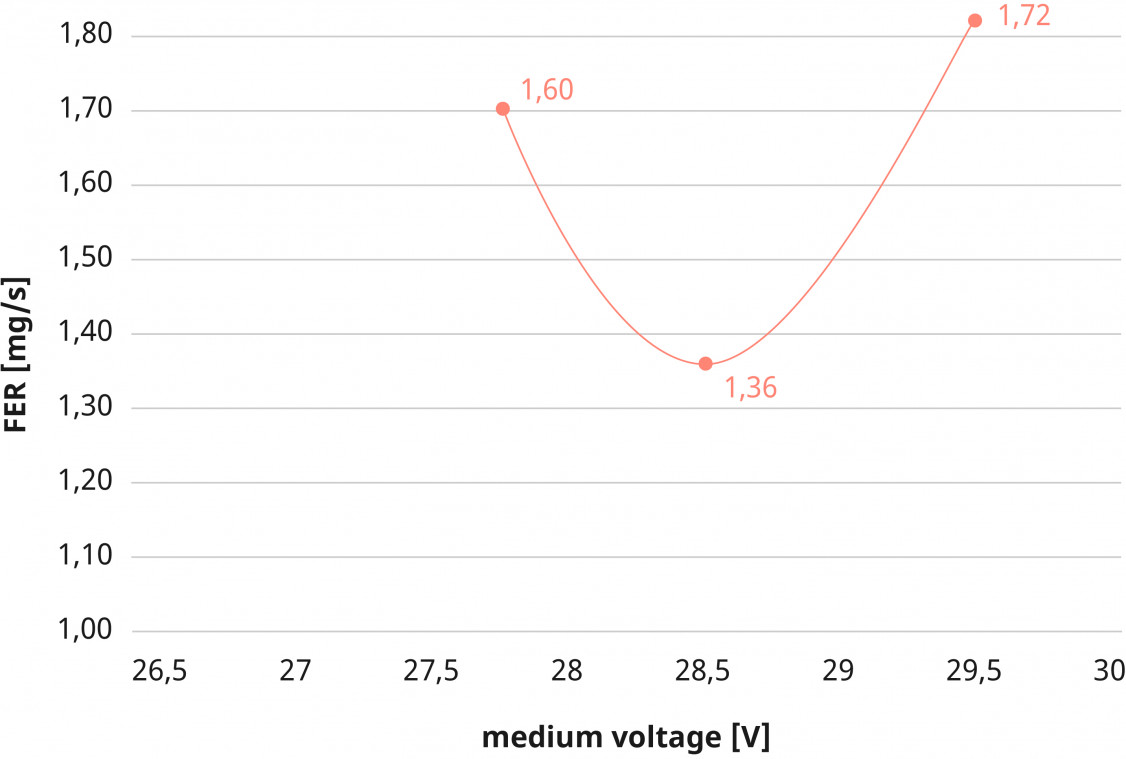

The welding fume emission rate correlates with the number of short circuits. A high number leads to a significantly higher FER. The study considers this to be due to material transfer. Short-circuit phenomena cause process disruptions that result in metal vapor and metal spatter. If you want to keep emissions to a minimum, it is advisable to use a process setting that brings arc length and short-circuit reduction down to a common denominator – that is, do not keep the arc too long or too short. With a slightly increased medium voltage, both short-circuit phenomena and emissions are reduced, Fig. 2.

The welding processes at 8 and 11 m/min behave in the same way as the process at 5 m/min in terms of the interplay between medium voltage, short-circuit phenomena and welding fume emissions.

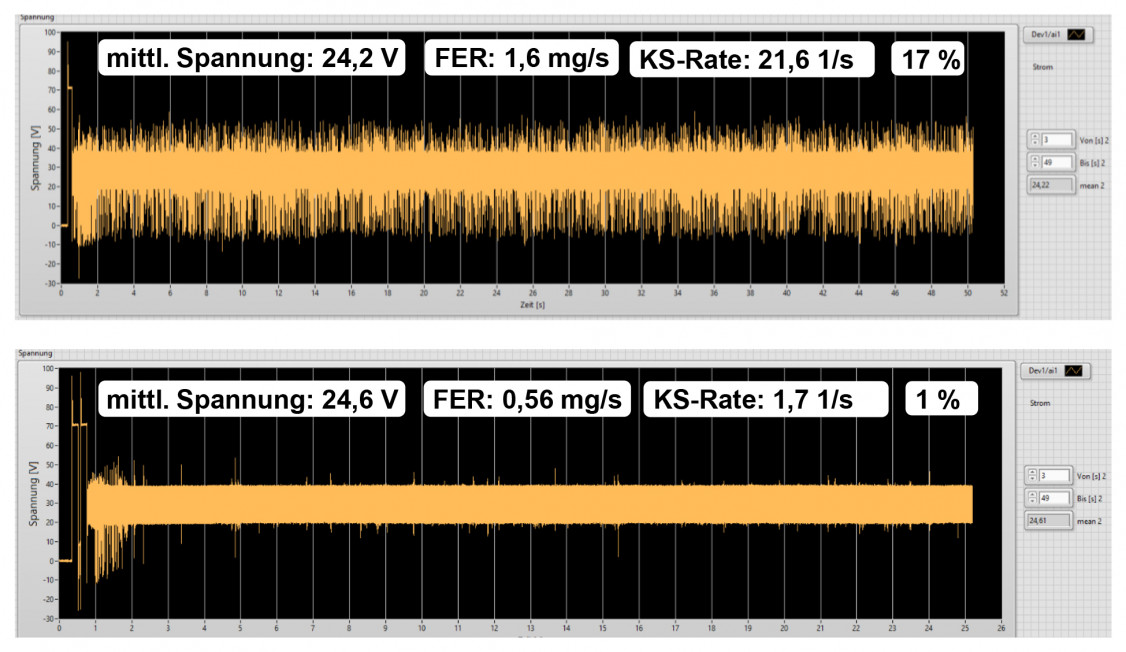

FER when welding fillet welds

Pulse welding with wire speeds of 5 m/min and 8 m/min results in significantly lower emission rates, 0.55 mg/s and 0.7 mg/s respectively, than with a wire speed of 11 m/s. Here, the emissions amount to 1.7 mg/s, more than three times that generated at a wire speed of 5 m/min. Similar to the surfacing beads, the reason for this is the lower number of short-circuit phenomena; here too the pull torch guidance technique also leads to lower emissions – with a considerably lower emission rate with a wire speed of 11 m/min, Fig. 3. In this case, the emissions are even lower than with a neutral welding torch position.

Overall, the welding fume emissions are at a lower level than with the surfacing beads. The lowest value of each of the wire speeds is comparable to the emissions of the optimized processes (see Figure 1, green bars) with which the surfacing beads were welded.

At a wire speed of 8 m/min, the welding fume emission rates for the push and pull welding torch position are very similar in absolute values – as was also the case with the surfacing beads. By contrast, the push welding process at 11 m/min reveals a significantly higher FER at around 2.8 mg/s.

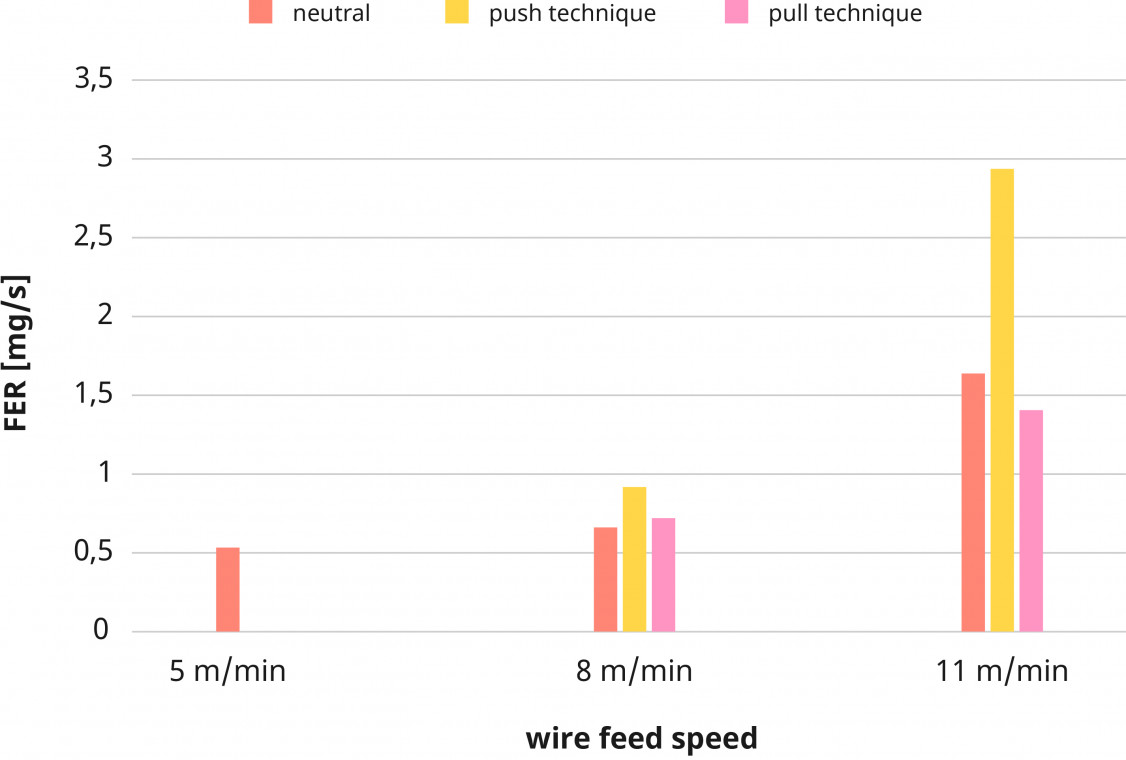

Comparison of the voltage curves at a wire speed of 11 m/min

In the FEF test, the relationship between emission rate and medium voltage at 11 m/min wire speed was studied more closely: With three measured values, there was a minimum at 1.36 mg/s (optimized with arc length correction -1.5 V). This is the operating point at which short-circuit phenomena occur sporadically, but the arc is not unnecessarily long. The process without arc length correction generates more emissions (1.72 mg/s) due to the longer arc and higher process performance. As the number of short-circuit phenomena increases with decreasing medium voltage (arc length correction -2.5 V), the welding fume emissions (1.6 mg/s) also increase, Fig. 4.

Conclusion: Welding-fume-optimized processes play an important role in reducing emissions.

Welders can take matters into their own hands: Welding fume production can be significantly reduced through the targeted selection of welding process, wire speed, and arc length. To summarize: Essentially, the welding fume emission rate depends on the deposition rate or process performance, with the material transfer being decisive. If an arc is too short or too long, this leads to higher short-circuit rates and thus to more welding fume emissions. If, on the other hand, the welding process is optimized using arc length correction and a fume extraction torch, such as the Fronius MTW 500i Exento in combination with a Fronius Exento HighVac extraction system, then up to 99 % of welding fumes can be extracted.

High-performance and precise extraction

Fume extraction torches prevent the welding fumes from dispersing at the point where they are generated – at the weld pool itself. They not only protect welding specialists when they are welding, but also anyone else who is in the vicinity of the workpiece. Since it is important welders are not adversely affected by a complex design in terms of their health and productivity, Fronius has paid particular attention to ergonomics when developing its fume extraction torches. An LED lamp facilitates welding in dark environments and supports quality control. Exento fume extraction torches meet the requirements of standard DIN EN ISO 21904-1 Health and safety in welding and allied processes.

(Source: Fronius Press Release)

Schlagworte

StudyWeldingWelding FumesWorkplace Safety