The automotive industry is facing major challenges: Robust and detailed processes are essential to ensure consistently high quality in the manufacture of components. Particularly for components made of modern material combinations, long-term stable, resilient joints are of crucial importance. This is especially true for the use of lightweight materials, such as fiberglass-to-plastic or plastic-to-metal bonds. Plasmatreat GmbH, based in Steinhagen, North Rhine-Westphalia, is setting new standards with its innovative plasma applications.

Plasma Technology Combines Cost-Effectiveness, Quality and Sustainability

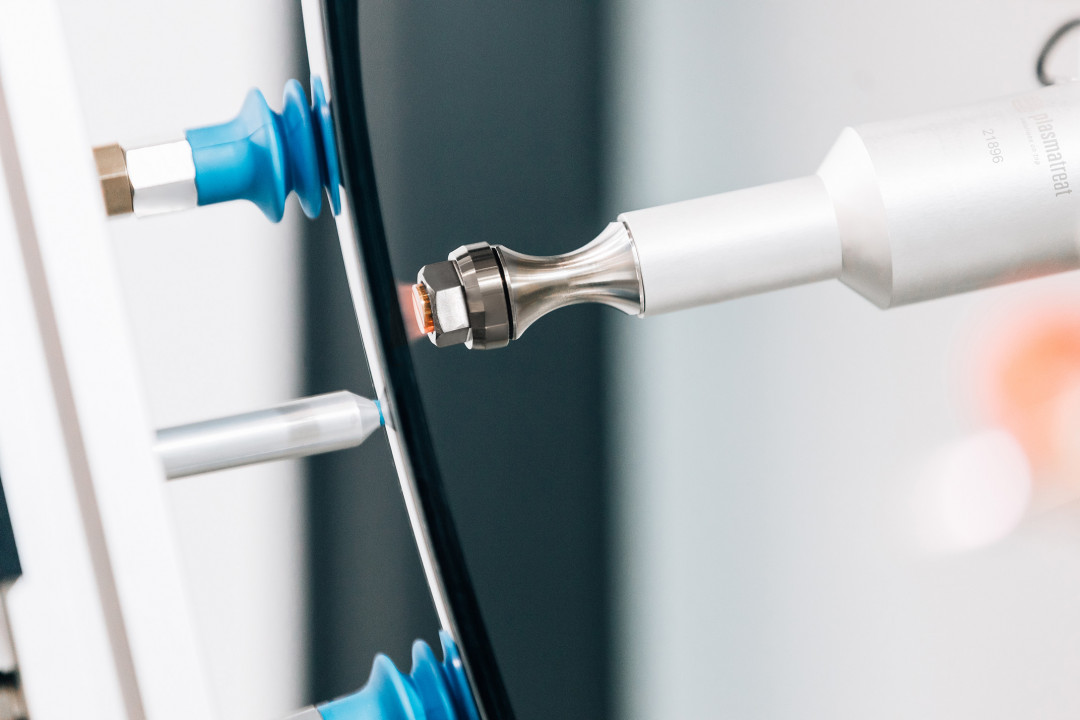

Openair-Plasma (atmospheric pressure plasma), developed by Plasmatreat, offers an environmentally friendly method of pretreating surfaces of various materials. Ultra-fine cleaning of metal or glass, for example, tailored to the material and application, removes contamination from surfaces and ensures the surface energy values required for further processing. Activation of plastics significantly improves the adhesion of adhesives, tapes, paints, varnishes and sealants. Plasma applications are dry, fully automated and highly reproducible due to optimal process control. They can be easily integrated inline into existing production lines and allow direct further processing. The use of environmentally harmful chemical bonding agents (primers) can be dispensed with. Overall, they improve quality, reduce complaints, extend product life, and significantly reduce costs.

Application examples from the automotive industry

The automotive industry in particular benefits from the advantages of plasma technology, as shown by examples from Plasmatreat's customer base.

- Headlights: State-of-the-art automotive lighting systems often consist of polypropylene and polycarbonate components. Openair-Plasma treatment ensures long-term adhesion and provides reliable protection against moisture penetration.

- Dashboard and interior trim: Plasma-treated plastic surfaces provide optimal adhesion for laminating or painting interior parts such as dashboards or door modules. This allows for precise, solvent-free processing that is both visually and functionally impressive.

- Batteries and cell-to-cell bonding: In battery manufacturing, the thermal conductivity of battery cells is optimized by activating films and coatings with Openair-Plasma. This contributes to greater efficiency and shorter charging times - an important advance in electromobility.

Optimum technology for the mobility of the future

Plasma applications have long been an integral part of the automotive industry. They promote the use of innovative materials, optimize quality, increase efficiency and support environmentally friendly processes. "Their versatility and sustainability advantages over conventional processes make them one of the preferred technologies for future mobility. At Fakuma, we will be happy to provide information on the full range of applications," explains Joachim Schüßler, Sales Manager Germany at Plasmatreat GmbH.

(Source: Press Release Plasmatreat GmbH)

Schlagworte

AdhesivesAutomotiveBatteriesBatteryBondingCarbonCleaningCoatingComponentsEnergyEnvironmentFAKUMAIndustryManufacturingMetalPlasticPlasticsPolypropylenProcessingSustainabilityTechnology