thyssenkrupp Aerospace and Boeing Sign Contract to Extend Long-Term Partnership

thyssenkrupp Aerospace and The Boeing Company have signed a contract extension, continuing their partnership that has stood since 1998. Based on the agreement, thyssenkrupp Aerospace, part of thyssenkrupp Materials Services, the largest materials distributor and service provider in the western world, will continue to provide dedicated supply chain management services, supply raw materials, and offer value-added services to Boeing and its worldwide network of subcontractors.

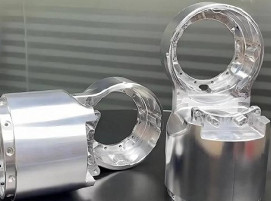

thyssenkrupp Aerospace works to ensure a secure supply to Boeing by leveraging its worldwide network. This includes operating multiple facilities across North America encompassing 167,200 m2 (1.8 million sq ft) that are entirely dedicated to providing raw material and value-added services to Boeing and its subcontractors in North America, Europe, and Asia. From these sites, thyssenkrupp Aerospace oversees the material management for Boeing for the supply of aluminum flat and extrusion products and titanium.

thyssenkrupp Aerospace manages a global control tower for Boeing’s materials supply chain, delivering solutions that go beyond the value-added services of a traditional materials distributor. thyssenkrupp Aerospace provides supply chain and materials optimization with a high focus on reducing risk, maximizing efficiency, managing, and delivering materials and parts exactly where and when they are needed. The company uses big data and advanced analytics to ensure material supply for Boeing amid global constraints and fast-changing economic and geopolitical conditions.

Patrick Marous, thyssenkrupp Aerospace CEO, said: “We have been working in close partnership with Boeing for more than 25 years and our relationship has demonstrated time and again to be effective at mitigating disruptions to the aerospace industry. This contract shows our continued commitment to providing long-term stability for Boeing’s supply chain.”

“We are delighted to continue this long-term partnership with thyssenkrupp Aerospace,” said Jeff Carpenter, Senior Director, Contracts & Category Management at Boeing. “With the dynamic nature of the aerospace industry, the flexibility inherent in this partnership supports our changing and evolving needs.”

The raw material for Boeing’s large network of subcontractors is managed by thyssenkrupp Aerospace, which allows for total demand aggregation, the ability to plan for ramp-ups and downs, reduced lead times, and other optimizations. With its holistic view of the end-to-end supply chain, thyssenkrupp Aerospace can supply material based on real-time business and market conditions.

“As part of our strategic development 'Materials as a Service', we are continuously working on the expansion of our service business,” says Ilse Henne, Chief Transformation Officer and Member of the Executive Board of thyssenkrupp Materials Services. “The extension of the contract with Boeing shows us that we are addressing the needs of our customers with our tailored solutions.”

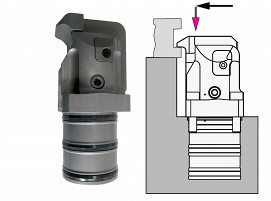

thyssenkrupp Aerospace is a global leader in providing supply chain solutions for the aerospace industry. The company's network comprises more than 40 locations in over 20 countries. Its more than 3,500 customers include the world's largest aerospace manufacturers and their suppliers. thyssenkrupp Aerospace offers supply chain management and a wide range of supply chain and manufacturing services. These include raw material sourcing, warehousing, precision machining, third-party logistics and just-in-time delivery.

(Source: Press Release of thyssenkrupp Materails Service GmbH)