You will find the company at the fair in Hall 5, Stand 5H17.

You will find the company at the fair in Hall 5, Stand 5H17.

![SCHWEISSEN & SCHNEIDEN 2025 [EN]](/images/frontend/journals/dvs-sus_sm.png)

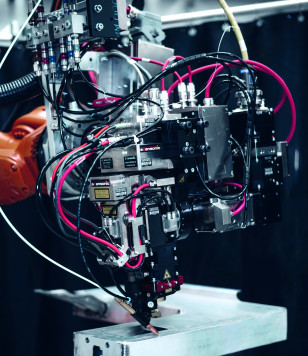

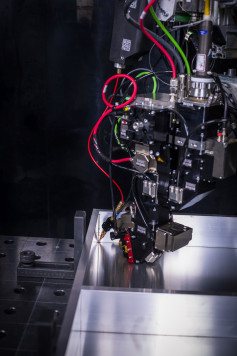

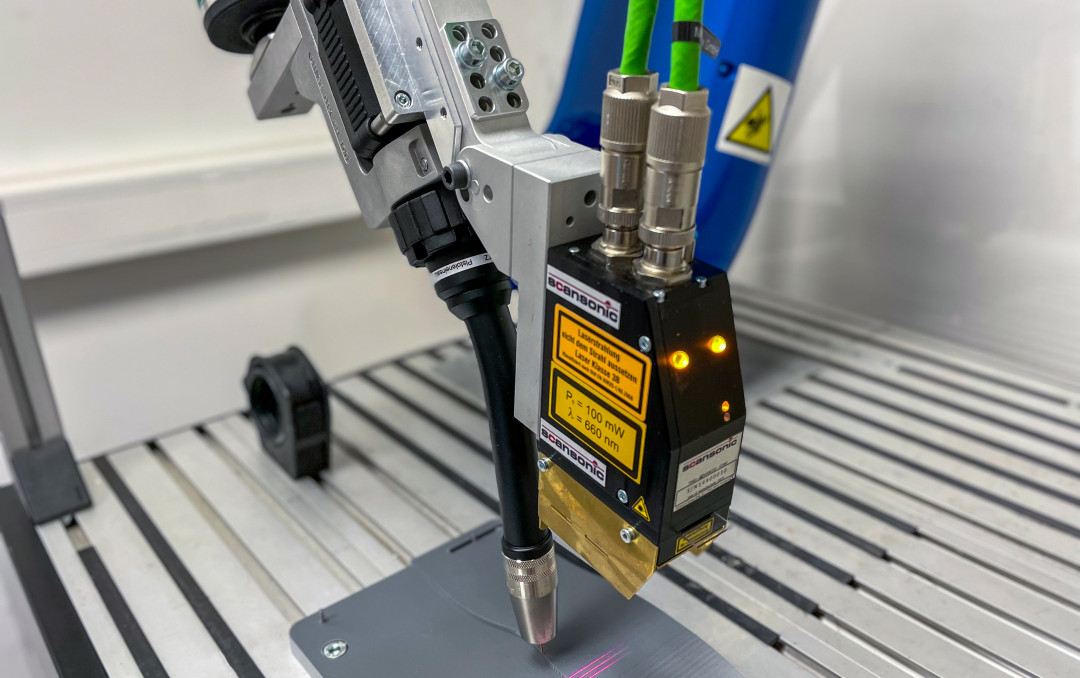

Scansonic will present its latest developments in laser welding, brazing and cutting at Essen. The exhibition will highlight processing optics and sensor solutions for demanding joining tasks, particularly for complex component geometries. A key feature of the exhibition is the enhanced ALO4 optics family for laser brazing and welding with filler wire and tactile seam tracking. Several variants have been developed for different joints, such as those found in battery case manufacturing. These variants enable wider connection cross-sections to increase seam strength, access to deep seam areas and vertical welding of corner joints. In collaboration with partner companies Dinse (wire feeding) and Brightlight Laser Systems (laser source), Scansonic offers these technologies as integrated complete solutions upon request.

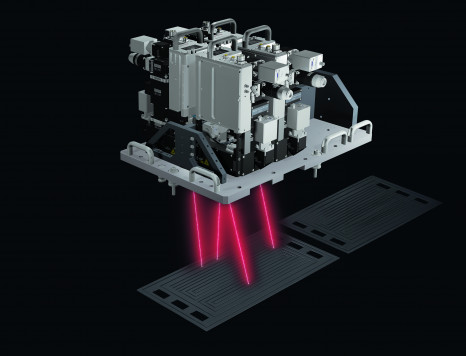

Also on display will be Scansonic's latest development: the SCW (Safe Component Welding) laser welding optics. It meets the requirements of Laser Class 1, allowing laser welding without a laser protection cell. The optics are based on the advanced FCW (Fast Component Welding) system technology, originally developed for tasks in electromobility. Multiple compact scanner units are combined on a process-specific carrier plate, enabling either larger components to be processed in one pass or several smaller components simultaneously – a solution particularly suited for high-cycle manufacturing processes and long seams.

Sensors for automated welding

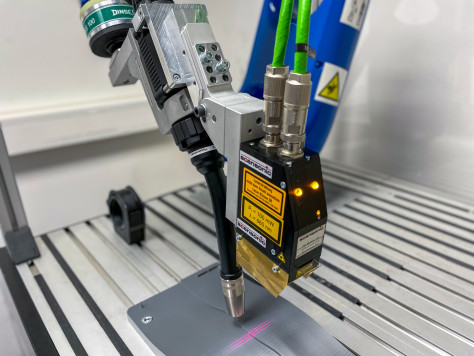

In the field of sensors, Scansonic, together with development partner Metrolux, will present new technologies for seam tracking in automated welding, brazing and adhesive processes – both for arc and laser processes. The new FH6D-Advanced sensor series for seam finding will make its debut. With a working distance of 150 or 350 mm, the sensors reliably measure the start and end points of the seam joint, enabling precise robot positioning even with component tolerances. These fundamental functionalities make the sensors ideal for entry-level automation. The sensors will be demonstrated live on a robot at the booth.

The new product line complements the existing portfolio of optical sensors for seam tracking. They guide the robot precisely along the component edge throughout the processing operation, using data from image processing and scalable pattern recognition algorithms. This eliminates the need for extensive reteaching during component changes or edge modifications.

(Source: Scansonic MI GmbH)

Schlagworte

AutomationBrazingComponent GeometriesConsumablesCuttingFairFillerInternationalJoiningLaserLaser WeldingMetalMetalworkingOpticsSCHWEISSEN & SCHNEIDEN 2025Trade FairWeldingWireWork