dry ice blasting for manufactured metal components

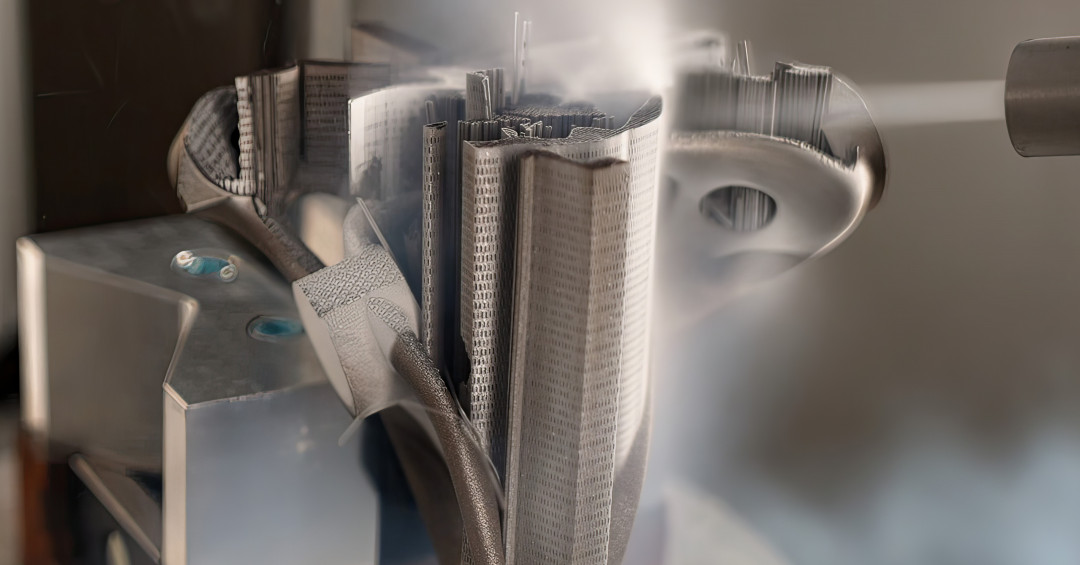

Over the last few years, additive manufacturing has fundamentally changed industrial manufacturing. Complex geometries can be produced without moulds, taking significantly less time and consuming fewer resources, which has opened up new possibilities, particularly in sectors such as aerospace, the automotive industry and medical technology. However, some process steps, such as removing support structures, are still undergoing constant development. This is where toolcraft AG has recently started using innovative dry ice blasting technology.

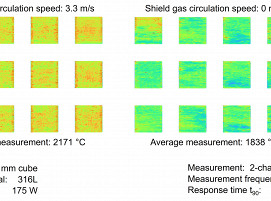

Removing supports efficiently and reliably

Removing support structures from additively manufactured components was once a time-intensive process that was also potentially prone to errors. Conventional methods, such as using a hammer and chisel, are not just time-consuming and physically demanding, but also increase the risk of damaging the component.

The SupportBlaster 320-HA is the dry ice blasting system developed by toolcraft. It is an efficient solution that semi-automates the process and improves the ergonomic working conditions. By doing so, it reduces bottlenecks and quality problems while increasing overall productivity. Depending on the specific requirements, it can reduce the machining time per component by up to 80 % – and sometimes even more, depending on the component. All while prioritising process reliability, high quality and the health and safety of employees. The automation provided by the dry ice blasting system also helps to increase economic and social sustainability. It not only reduces production times and costs, but also improves working conditions by minimising physically strenuous work.

Innovation for the future of additive manufacturing

With its innovative dry ice blasting technology, toolcraft demonstrates how modern technologies can contribute to increasing the efficiency and quality of additive manufacturing. “Companies that continue to rely on traditional, manual processes are going to find themselves under pressure in the future. The market is increasingly demanding automated solutions supported by technology”, says Christoph Hauck, Chief Technology and Sales Officer at toolcraft AG. He believes that the combination of additive manufacturing and modern finishing techniques are an important competitive advantage, particularly in high-tech sectors such as aerospace and the semiconductor industry.

(Source: toolcraft AG)