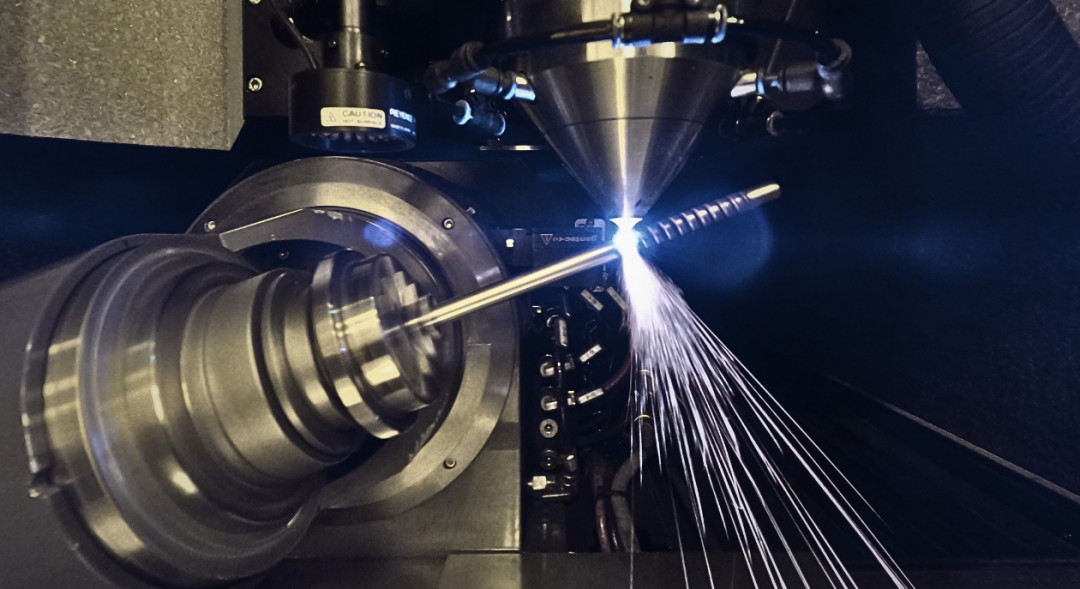

Non-contact laser turning for delicate workpieces

Laser turning combines the properties of conventional turning with the advantages of lasers. Since the laser beam does not make direct contact with the workpiece, the component is machined without mechanical stress, a crucial feature for sensitive or very small components. The use of ultrashort pulse lasers (USP) ensures minimal thermal stress on the material.

The absence of force during laser turning enables the manufacturing of components with diameters of up to 0.15 mm. The laser's precision allows for drilling of cross holes that would be difficult or impossible to realize using traditional turning processes. The result is smooth, flawless surfaces with a roughness of Ra <0.05 µm that require no additional post-processing.

Versatility in material selection

A key benefit of laser turning is the wide range of materials it can process. The process allows for precise machining of a wide range of materials. This versatility extends to materials that are challenging to machine using traditional turning processes, including those with high hardness and brittleness.

For precision mechanics

Laser turning is a highly effective process for micro-tweezers, ultra-fine electronic contacts and delicate watch indicators. In one of the first customer projects, laser turning was used to produce micro screws for a progressing cavity pump. BBW Lasertechnik is planning to commence series production in the near future.

(Source: BBW Lasertechnik)