BLT Introduces the BLT-S800 Metal 3D Printer with 20 Lasers

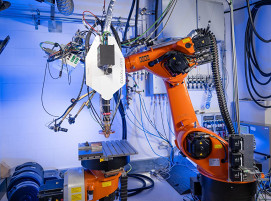

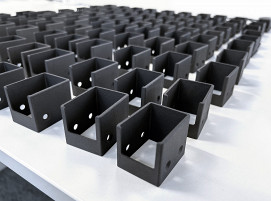

Bright Laser Technologies (BLT) has just unveiled the BLT-S800 metal 3D printer, featuring an extra-large build volume (800 mm × 800 mm × 600 mm) and configuring with 20 fiber lasers to shorten the part delivery cycle time and enable rapid research and manufacturing for customers. BLT-S800 can work with titanium alloy, aluminum alloy, high-temperature alloy, stainless steel, high-strength steel, and tool steel. Its applications span across various industries, including aviation, aerospace, engine, medical, automotive, electronics, mold, and research institutes.

“By investing a decade in large format and multi-laser printing, the BLT-S800 has excelled in system stability. Currently, we have deployed dozens of BLT-S800, 20-laser printers in our customers' factories, and their reliability and usability have been tested in the market,” said Eliza Duan, head of International Business Department, BLT.

Boosting Production with 20 Synchronized Lasers

Within the same floor space, increasing the number of optical paths directly increases production capacity and plant efficiency without the need for extra equipment, additional factory space, or more operating personnel.

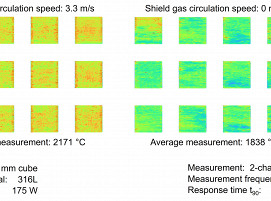

Advancements in Wind Field Optimization

In the realm of wind field optimization, innovative solutions have been implemented to support the synchronized operation of 20 lasers. These innovations effectively disperse any black smoke and splatter generated during multi-laser printing, ensuring parts quality. Simultaneously, they ensure the optical lenses remain clean, guaranteeing uninterrupted printing processes.

Enhanced Serial Production with the Powder Circulation System

Efficient powder recovery plays a pivotal role in mass production workflows. The BLT-S800 introduces an innovative powder circulation system designed to safely transfer, recover, sieve, and recycle metal powders in an on-site test lab. This system simplifies and secures the movement of large volumes of 3D printing powders from containers to multiple machines, effectively eliminating the risks associated with spillage, contamination, explosions, or contact with personnel. This system empowers manufacturers to meet their serial production needs while achieving substantial cost savings in their operational endeavors.

Enhancing Production Efficiency through In-House Software

Configured with BLT-BP, the BLT-S800 offers the capability for streamlined profiling of large-sized parts. This reduces the time spent on profiling and preparation and enhances efficiency during the printing process. Even for parts with a substantial 25G data volume, the required profiling time is merely 30 minutes. Furthermore, the BLT-BP on the BLT-S800 has a dynamic powder laying strategy that adapts powder fusion speed to the part contour, enabling multi-stage automatic speed adjustments. This approach ensures both quality and efficiency. Typical parts experience a notable 30 percent improvement in single-layer efficiency compared to the conventional method.

(Source: BLT Press Release)