Alleima’s sustainability targets have been reviewed and validated by the Science Based Targets initiative (SBTi) and are now aligned with the latest climate research. These targets mean that Alleima is reducing its Scope 1 and 2 CO2 emissions by more than 54 % and Scope 3 emissions by 28 % by 2030, using 2019 as the base year. Alleima has already reduced its Scope 1 and 2 CO2 emissions by 41%, well ahead of schedule. To continue this progress, Alleima will focus on various technical solutions for electrification and energy efficiency as well as hydrogen and biogas.

Rising CO2 emissions and other greenhouse gases are the main drivers of global climate change. For Alleima, sustainability is an integral part of the company’s operations, and its targets for reducing GHG emissions have been validated by the SBTi, confirming that the company’s climate targets are scientifically supported. “We are an industry leader in sustainability, both through our product offering and our own climate footprint. A small carbon footprint is part of our premium offering to our customers. Our deliveries are included in our customers’ Scope 3 emissions, and it is through our products that we can make a real difference for them. Ensuring that we continue to create additional customer value by further reducing our CO2 emissions is crucial for achieving our targets,” says Göran Björkman, CEO of Alleima.

Alleima’s CO2 emissions are already relatively low because the company uses recycled materials and electric arc furnaces in its steel production. Of the more than 54 % reduction to be achieved by 2030, compared with 2019, the company has already cut emissions by 41 % (Q3 2025) through the use of fossil-free electricity and biogas. The company has made steady progress in reducing emissions over the years, with the goal of achieving net zero emissions by 2050 at the latest.

“We have come a long way toward achieving our targets. 97 % of all electricity used globally is now fossil-free. We have invested heavily in energy efficiency, and we have replaced LPG with biogas at several locations across our operations. This shows that we are taking our responsibility, following our ambitious targets, and are committed to reducing our emissions,” says Håkan Sundström, Head of Sustainability at Alleima.

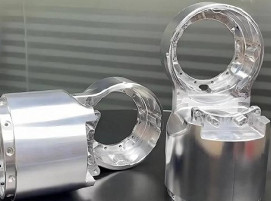

The largest share of Alleima’s CO2 emissions (approximately 80 % of the company’s total emissions) occurs in Sandviken, where the steel mill – with smelting, casting, rolling and forging plants – is located. The company is therefore continually evaluating various technical solutions to reduce its emissions through measures such as electrification, biogas or hydrogen, which will lead to a halving of emissions by 2030. To convert certain heating processes from fossil fuels to electrical solutions, for example, Alleima is working with experts in its Kanthal division. The heating of mold tubes in continuous casting has recently been electrified in partnership with Kanthal, the supplier of high-tech heating solutions.

“We have a clear plan going forward that is flexible and can be adapted depending on technological development and availability. In addition to direct electrification, biogas will be used as a supplement, especially during the transition to electrification, and hydrogen will be the solution in selected cases. The close collaboration with our colleagues in the Kanthal division, who are experts in electric heating, is also very gratifying,” says Carl von Schantz, President of the Tube division.

Apart from the SBTi validation, Alleima was recently once again awarded a gold medal by EcoVadis, a leading supplier of sustainability assessments. This prestigious recognition of sustainable business practices places Alleima among the top 5 % of 150,000 companies evaluated across the globe.

(Source: Allmeia AB)

Schlagworte

Carbon FootprintCarbon ReductionClimateCO2ElectrifictionEnergyNetZeroScope 1Scope 2Scope 3Steel