You will find the company at the fair in Hall 3, Stand 3B55.

You will find the company at the fair in Hall 3, Stand 3B55.

![SCHWEISSEN & SCHNEIDEN 2025 [EN]](/images/frontend/journals/dvs-sus_sm.png)

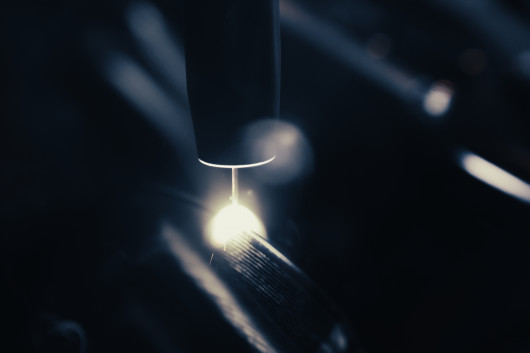

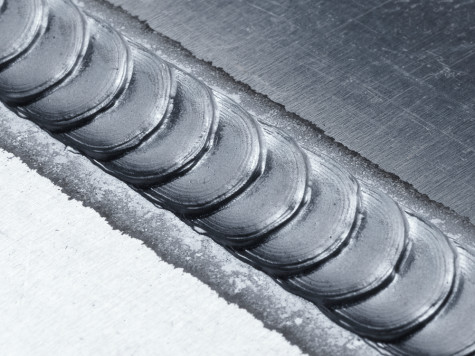

The CMT process is based on a reversing wire movement that enables controlled droplet detachment. This movement ensures a stable arc and minimizes heat input. This results in almost spatter-free, clean welds that have a high quality and aesthetics. Another advantage of the CMT process is the low thermal load on the workpiece. This reduces distortion and deformation, which is an enormous advantage especially when working with sheets as thin as 0.3 millimeters and temperature-sensitive materials. Precise control of the welding process helps tackle demanding welding tasks with the highest degree of accuracy.

CMT opens up the possibility of joining different materials together. For example, galvanized steel and aluminum can be welded safely and reliably. This creates scope for creative solutions in the production process.

Variety of applications in different industries

“Over the last two decades, CMT has established itself as a versatile welding process that is used in numerous industries. Sometimes even we are impressed by the diversity and creativity with which our customers use CMT to their advantage and to solve their welding challenges,” says Franziska Eichhorn, Strategic Product Manager, Fronius International.

The automotive industry, for example, uses CMT to join thin sheets and lightweight materials such as aluminum, ensuring strong and reliable connections for vehicle frames and components. CMT has also proven its worth in the aerospace industry, where the process allows the welding of high-strength and lightweight materials that are essential for the construction of aircraft and spacecraft.

In addition, due to the outstanding stability of the welding process, CMT is used in 3D printing or in the electronics industry, where it is used to precisely braze components.

Intelligent air gap detection and edge detection thanks to CMT

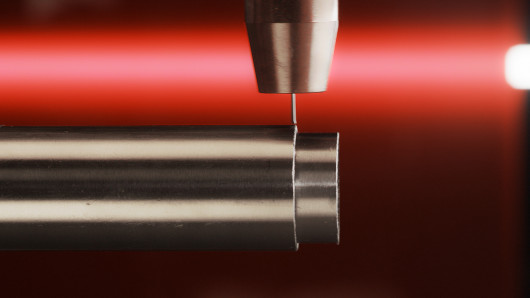

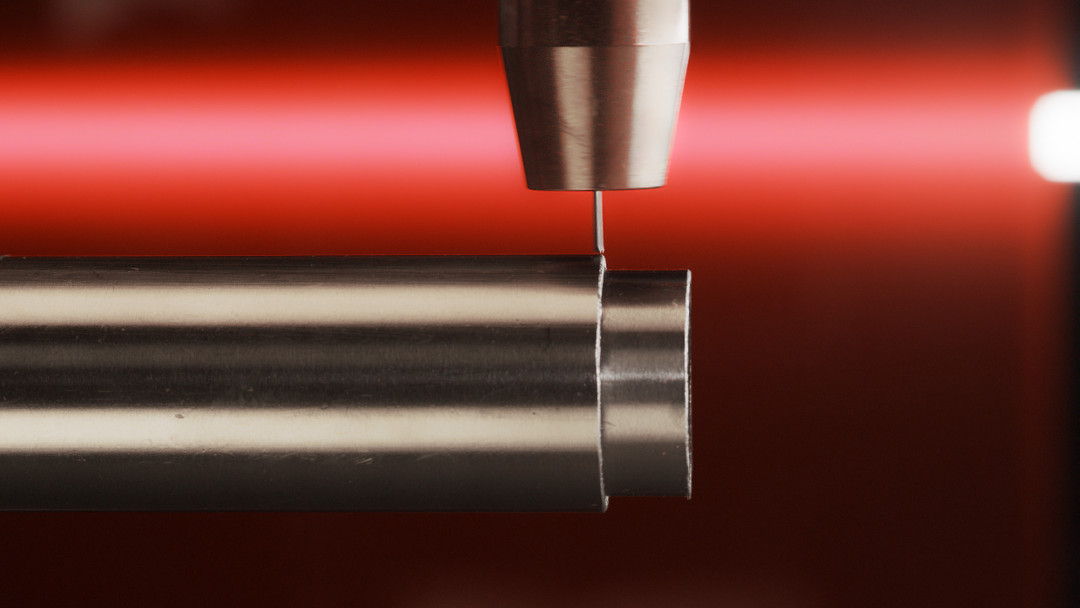

CMT’s back-and-forth movement of the wire has also revolutionized robotic welding with the WireSense intelligent assistance system. This significantly improves the seam quality and efficiency by detecting inaccuracies and deviations in industrial production and avoiding them by means of the CMT welding process. The welding wire serves as a precise sensor that precisely determines the position of the weld and dynamically adjusts it. This saves material, time, and costs, as rework and rejects are reduced.

CMT is fit for the future

“The decisive factor is the perfect interaction of the components and the precision with which they are controlled,” emphasizes Eichhorn. “The harmony with which our intelligent welding machines and the Robacta Drive CMT drive unit – in other words the second wirefeeder directly on the torch – work together is still unmatched today and is constantly being further developed to meet the increasing demands of the industry. And the best thing about it: CMT can be easily retrofitted to all intelligent Fronius devices.” Over the years, Fronius advanced CMT and developed application-specific optimized welding characteristics such as CMT Mix, CMT Cycle Step, CMT Cladding, and CMT Braze.

LaserHybrid CMT, on the other hand, combines the advantages of laser welding with CMT technology. When used on high-strength steels and aluminum components, this combination boasts high speed, quality, and cost-effectiveness. A highly focused laser beam that penetrates the base material with a high energy density is immediately followed by the CMT process, which increases the seam volume and can further reduce the heat input.

The latest achievements are the CMT Additive Pro characteristics optimized for metal 3D printing, which take additive manufacturing to a new level.

The Fronius team wil be demonstrating CMT and their other innovations at the SCHWEISSEN & SCHNEIDEN trade show in Essen, Germany, Hall 3, Stand 3B55.

(Source: Fronius International GmbH)

Schlagworte

AerospaceAIAircraftsAutomotiveBrazingCMTIndustryInnovationInternationalJoiningLaserLaser WeldingLEDLightweightManufacturingMetalRobotRobotic WeldingSolderingTorchTradeWeldingWireWires