Hydrogen is set to become the energy source of the future: versatile in use, producible from renewable energy and extremely efficient as a fuel and for the storage of energy. The European Union recognises hydrogen's key role in the decarbonisation of industry and thus in the energy turnaround with its hydrogen strategy. The goal of this strategy is to achieve annual production of 10 Mio. t of green hydrogen within Europe by 2030, along with an additional 10 Mio. t of hydrogen imports. The precondition for this is the availability of the corresponding infrastructure, in the form of a Europe-wide hydrogen transmission grid.

The so-called European Hydrogen Backbone (EHB) will be established by converting approximately 70 % of existing natural-gas pipelines and constructing new hydrogen pipelines for the remaining 30 %. The Greek pipe producer, Corinth Pipeworks S.A. (CPW) and Dillinger, a large European heavy-plate maker, located in Germany's Saarland, are pursuing the construction of high-pressure gas pipelines for hydrogen of up to 100 % purity. An example of this is their successful cooperation in Poland and Italy on the first European pipelines certified for pure hydrogen.

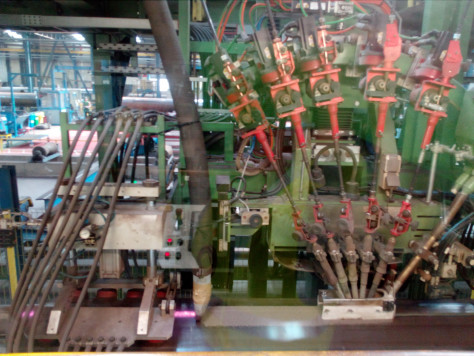

Corinth Pipeworks is a global Tier 1 supplier of steel pipes. Over 90 % of the company's product and service portfolio is enhanced by its Research & Development activities in linepipe systems for the energy sector. In all areas of activity, the company adheres to the principle of the one-stop shop, ensuring that customers receive comprehensive solutions from a single source. This is why the company exclusively supplies all welded products for hydrogen pipelines, covering everything from production, certification (in its state-of-the-art hydrogen laboratory) and finally the delivery at site. Founded in Corinth in 1969, the company opened its new production facility, featuring exclusive access to the harbour, in Thisvi, Viotia, in 2000. The plant site extends more than 800,000 m2, of which 130,000 m2 are covered and accommodates ten major production sites: four welded pipe-making mills covering a wide diameter range of 2.5’’ to 100’’, two external and one internal coating mills, one concrete-weight coating mill and a pipe double-joining facility. The facility’s annual production capacity reaches up to 1 million tonnes. The company has been a subsidiary of Cenergy Holdings SA since 2016, following a cross-border merger that absorbed the formerly listed companies Corinth Pipeworks Holdings S.A. and Hellenic Cables Holdings S.A.

Dillinger is producing high-quality heavy steel plates. These high-tech plates are used in technically demanding projects in the fields of structural-steel engineering, offshore and onshore construction, wind power, linepipe, pressure vessels and mechanical engineering. From hot metal (unrefined iron) and steelmaking, via two rolling mills, up to and including commercial departments, thermal-cutting and semi-fabrication facilities, Dillinger is also a single-source supplier for everything needed. Corinth Pipeworks and Dillinger are linked by many years of mutually confident cooperation.

Pioneer with an in-house hydrogen laboratory

In 2020, Corinth Pipeworks established an Emerging Fuels Team in order to define and energetically pursue a strategy for future-orientated development of pipe technology. This team consists of three experts with more than two decades of service for the company: Athanassios Tazedakis, Senior Operations Director, Metallurgical Engineer and Ph.D. in Welding, Nikolaos Voudouris, Head of Engineering & Technology, Chemical Engineer and Ph.D. in Materials Science, and Efthymios Dourdounis, Head of Quality Assurance, Chemical Engineer and Ph.D. in Metallurgy.

Facing a lack of European standardization for hydrogen pipelines, Corinth Pipeworks developed protocols based on the ASME B31.12 code published at the United States. Corinth Pipeworks integrated the code requirements into a standardized testing and qualification procedure for pipes (plate material and weld) to achieve certification of the product in accordance with ASME Code B31.12 Option B. This certification applies to hydrogen pipes used for transmitting hydrogen/natural gas mixtures and pure gaseous hydrogen without any design restrictions for onshore applications.

Apart from the qualification protocol, CPW has developed it’s testing capabilities. The company is currently the only pipe producer in the world to possess an in-house modern hydrogen laboratory for the testing and certification of pipes for pure hydrogen under steady-state and/or rising loading conditions and at high pressures of up to 300 bar. Testing is based on ASME Code B31.12 and other relevant standards and evaluates toughness and ductility reduction caused by hydrogen embrittlement. This knowledge of hydrogen-specific phenomena enables the supply of end products with the necessary level of safety and provide deeper insights into the design requirements of gas-grid operators.

Today, CPW leverages its knowledge and expertise in steel grades, thicknesses and pipeline technology to maintain a significant competitive edge. This ensures the demonstrable safety, suitability and design of their products. "The fact that the steel behaves the way we predicted on the basis of our experience with this company and on our Finite Element (FEM) analyses for the specific product, is of extreme importance," notes Athanassios Tazedakis, highlighting the significance of this cooperation.

High-pressure gas pipeline for Poland

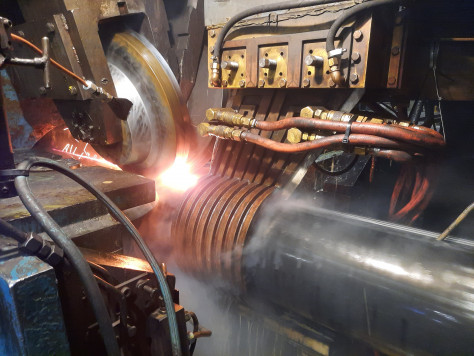

Corinth Pipeworks has long served Polish gas-grid operator GAZ-System Poland SA. In 2021, alongside establishing its hydrogen testing lab, the company received an order for an 80 km high-pressure pipeline, initially for natural gas but designed for future hydrogen use as part of the European Hydrogen Backbone. Corinth Pipeworks' standardised test and certification procedure, as provided by its in-house hydrogen laboratory, convinced GAZ-System to adopt the requirements of the ASME Code into its own specifications for the planned high-pressure gas pipeline. This pipeline, running from Gustoržyn to Wronów, is a section in a larger high-pressure gas pipeline. The longitudinally submerged arc welded (LSAW) pipeline has a diameter of 1,016 mm, with a wall thickness of 22.2 mm. Externally, it features a triple-layer polyethylene coating for protection against corrosion and, internally, an epoxy-resin coating.

The pipeline's operating pressure of 80 bar conforms to the typical pressure for transmission pipelines used in Europe. As Efthymios Dourdounis emphasises: "We tested the pipe at a much higher pressure than the operating pressure and it consistently withstood pressures of even 200 bar." Athanassios Tazedakis adds: "In order to meet and exceed the applicable specification requirements, we must be very cautious and conservative when selecting our partners. Our choice fell on Dillinger, which supplied 11,000 t of heavy plate in grade L485ME for this section. This is the highest steel grade that may be qualified for hydrogen applications, as per ASME B31.12", explains Efthymios Dourdounis, adding: "Grades L415, L450, and L485 are more commonly used. However, the selection of L485ME grade, as specified by GAZ-System, permits a lower wall thickness due to its high mechanical properties (i.e., yield strength), resulting in less steel being needed for the same design pressure."

Tailor-made heavy plates for hydrogen pipelines

The selection of Dillinger as the supplier was based on extensive data regarding steel properties, the specific requirements set by Corinth Pipeworks and Dillinger’s proven track record. According to Nikolaos Voudouris, what proved decisive for the pipe maker was the ability of the plates to be formed in a way that met the demanding specifications for hydrogen pipelines. “We set strict requirements for the chemical analysis and the mechanical properties of the steel, which we ourselves must guarantee in order to ensure high-quality pipes. In this context, it was critical that the pipe plate behaved predictably during forming, so that welding preparation could be carried out correctly. The preceding FEM analysis defined in detail how each forming station and plate had to be applied for the specific pipe designs. “We don’t produce standard, off-the-shelf pipes; every project is designed from the ground up. Our customers provide designs for clearly defined applications, with requirements specified in detail. The steel supplier must therefore design the steel not only to meet customer requirements but also to comply with all relevant technical standards, including those specific to hydrogen. With Dillinger, we are confident that the plate will deliver on our expectations and predictions: high oxide cleanliness due to low phosphorus and sulphur levels, a lean microstructure with low carbon content, low hardness, ductility, and excellent weldability.”

Onshore and offshore pipelines

In the expert view, the critical applications for hydrogen will herald in a new era in which the challenges arising must be tackled together. The conversion of existing pipelines will demand high economic sacrifices from the gas-grid operators: they will be required to inspect the entire length of the pipeline and reduce the pipeline pressure for the transmission of hydrogen if any defects or suspect areas, which might be non-critical for natural gas, are found. In addition, and due to the lower energy density of hydrogen, hydrogen-transmission pipelines are profitable only with high flow rates, with the result that hydrogen is expected to arouse high demand for completely new pipelines. Corinth Pipeworks is once again pioneering a variety of projects aimed at developing the currently missing standards for offshore pipelines."Qualification of these pipelines for submarine transmission must be based on stringent incoming goods inspections and material validations. So, both we and Dillinger must be equally prepared for this!"

(Source: Dillinger)

Schlagworte

EnergyEUEuropeGas PipesHeavy Steel PlatesHydrogenLSAWPipesSteelWelding