Fronius is continuously working to improve precise metering of shielding gas. Both excess and insufficient gas can compromise weld quality. Shielding gas is a valuable and costly resource and its production consumes significant energy, contributing to a substantial carbon footprint. The gas control system from Fronius optimizes shielding gas utilization, ensuring consistently high welding quality while reducing gas consumption by up to 40%.

Whether argon, helium or mixed gases, shielding gas is essential for a stable arc and perfect welding results. Too little gas does not provide sufficient protection, allowing ambient air to penetrate the welding point. The consequences are oxidation and porosity of the weld seams, increased spatter and an unstable arc. Too much shielding gas is a waste of resources and also leads to problems. Excessive gas flow causes turbulence, which impairs the gas shield and also leads to air admixtures. With the negative effects being similar to those of an insufficient gas feed, reconciling the demands of quality, cost, and resource efficiency becomes a significant challenge.

Reducing gas costs = saving resources

A controlled gas setting for the respective welding process, material or welding position ensures good weld quality and reduces costs. “Our intelligent gas controller not only ensures that the arc and weld pool are protected, but it also makes it possible to significantly reduce gas consumption in two ways,” explains Philipp Schlor, Strategic Product Manager at Fronius International. “Firstly, it eliminates the so-called blow out with every single welding start. On the other hand, it allows the shielding gas quantity to be regulated according to output or precisely set in advance for each individual welding job. Our experience shows gas savings of up to 40 % can be achieved. For some customers, this value is even significantly higher if many short seams are welded, for example. In addition, consuming fewer resources lowers the carbon footprint of the manufactured components and the company as a whole: a factor that is gaining importance and increases competitiveness.”

Optimal shielding gas conditions for every welding initiation

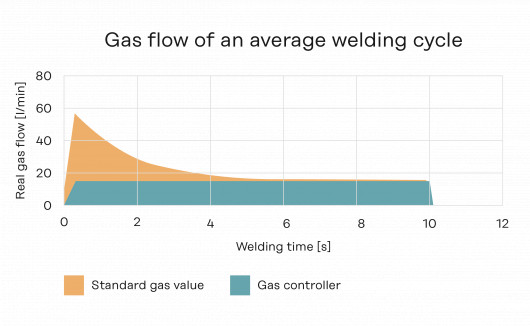

Every welding start – whether for tacking or for seams of any length – begins with a gas shroud being formed before arc ignition to protect it from the atmospheric air. However, when welding starts, the set flow rate that should be available for welding is briefly exceeded. The Fronius gas regulator smooths this blow out and ensures that no gas is wasted.

A comparison between a conventional gas solenoid valve and an intelligent gas controller illustrates the difference. If, for example, a gas flow of 18 l/min is required, the Fronius gas controller establishes it instantly and maintains it at a consistent level. With a gas solenoid valve, on the other hand, the gas flow increases for a short time up to 55 l/min and then adjusts back down to the preset required level. The difference in consumption is evident at every welding ignition – and the more frequent and shorter the seams, the greater the savings.

Optimal gas control for each welding job

Standard gas solenoid valves switch the set gas flow on and off after the gas pressure regulator. The flow rate is defined for each component with one value for every weld. In practice, this means the gas flow rate is set to meet the highest demand required by any weld seam on the entire component. In other words, if 15 different seams need to be welded on the same component and one of these welds is in a constrained position, that particular weld determines the minimum flow rate required for all other seams. To counteract this waste, the high-tech Fronius TPS/i and iWave welding solutions equipped with the intelligent gas controller regulate the gas flow depending on the output or allow individual gas dosing for each job. All Fronius TPS/i and iWave welding solutions can also be retrofitted with an intelligent Fronius gas controller at any time.

(Source: Fronius International GmbH)

Schlagworte

Arc WeldingControllerEnergyGasResourcesWelding