Sven Müller, Tim Radel

1. Introduction

During additive manufacturing of metallic components using laser powder bed fusion, heat accumulations in the process zone can have a negative impact on component quality, necessitate process interruptions and are one of the reasons for the need for support structures [1]. If constant process parameters are used, heat accumulations can only be prevented to a limited extent due to varying areas for heat dissipation [2]. In order to improve the quality of components additively manufactured using laser powder bed fusion, it is therefore common practice to divide the components into different overhang, contour and internal volume areas and to optimise the process parameters for each area individually. Although this allows high component quality to be achieved, this method is associated with high time and material efforts and is therefore cost-intensive. In order to make this conventional, component area-dependent parameter optimisation obsolete and to simplify the application of laser powder bed fusion, an in-situ control concept is required that can prevent heat accumulation regardless of the component geometry. For this reason, the suitability of a spatially resolved process control based on temperature fields to enable high component quality was investigated. Coaxial 2-channel-pyrometer measurements were used to generate temporally and spatially high-resolution temperature maps of each layer in the powder bed process. Using this method, heat accumulations can be detected and quantified in-situ. The quantified information regarding the heat accumulation present in individual component areas is then used to adjust the laser power used in the process automatically and with local resolution in the subsequent layer.

2 Experimental

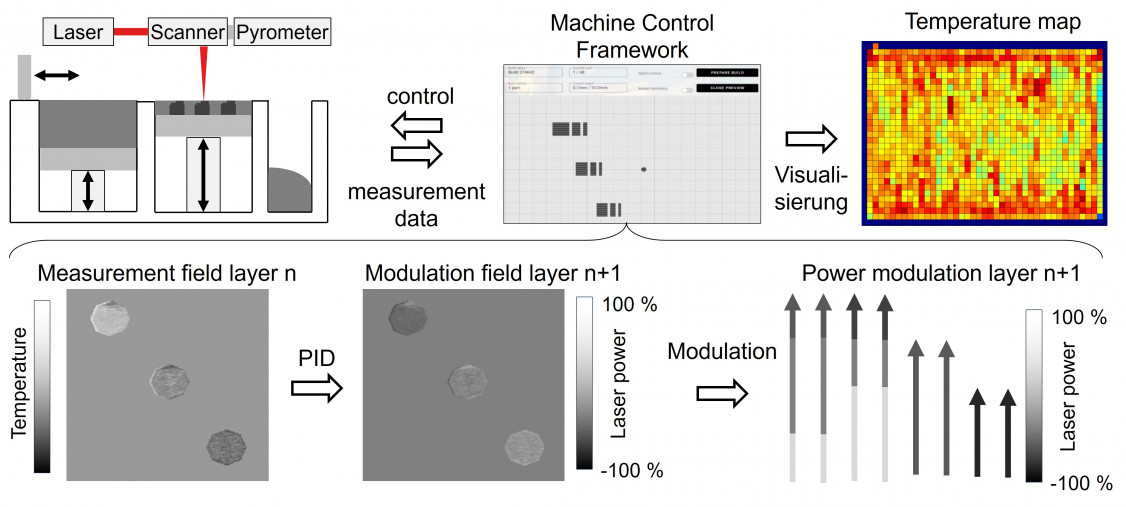

During the investigations, a PBF-LB/M setup was used, which consists of a 3D laser scanning system (fiberSYS from Scanlab), a 2 kW fibre laser (TruFiber 2000 P compact from Trumpf) and a process chamber with a build chamber diameter of 100 mm. The process was controlled using the Autodesk Machine Control Framework, in which the control of the axes and the laser scanning system, the recording and processing of the measurement and position data and the implementation of the control loops were implemented. A circulation pump (WT101 from Wetravent) was used for the shielding gas circulation, whereby the circulation speeds were calculated based on the measured volume flow rate and the cross-section of the circulation inlet. 316L substrates and 316L powder with a particle size distribution between 15 μm and 45 μm were used during the experiments. The fibre laser used has a beam diameter of 55 μm in the working plane with a Gaussian intensity distribution. Argon was used to create an inert gas atmosphere with an oxygen content of less than 0.3 %. A high-speed dual-channel pyrometer (H322 from Sensortherm) with a measuring frequency of 25 kHz, a spectral range of 1.65 μm to 1.8 μm and 1.45 μm to 1.65 μm for channel 1 and channel 2 respectively, a response time t90 of 0.08 ms and a measuring range of 1000°C to 3000°C was used for coaxial temperature measurements While the intensity of the thermal radiation and thus the illumination of the measurement spot is relevant for single-channel pyrometric measurements [3], the measured value for the dual-channel measurement principle reflects the maximum temperature present in the melt, regardless of the measurement spot illumination. During the PBF-LB/M process, the x and y coordinates of the laser spot and the pyrometer measurements were synchronised with a real-time interface at 50 kHz (Open Interface Extension from Scanlab). The coordinates and sensor signals were only recorded during the laser emission. Based on the spatially resolved sensor signals, temperature maps were created, which are divided into pixels. The pixel temperature reflects the average temperature of the measuring points contained in the pixel. The deviation from a defined target temperature is then determined for each pixel using a PID control loop and a corresponding control factor is calculated. The resulting control factors are used in the subsequent layer to adjust the laser power with spatial resolution and thus also within the scan vectors. A schematic representation of the system used is shown in Figure 1.

2.1 Results

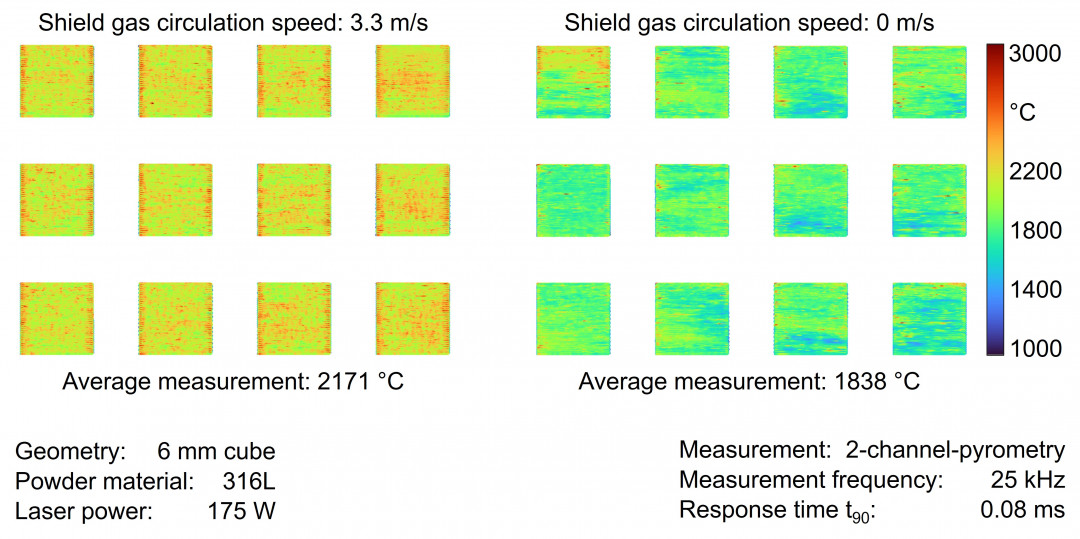

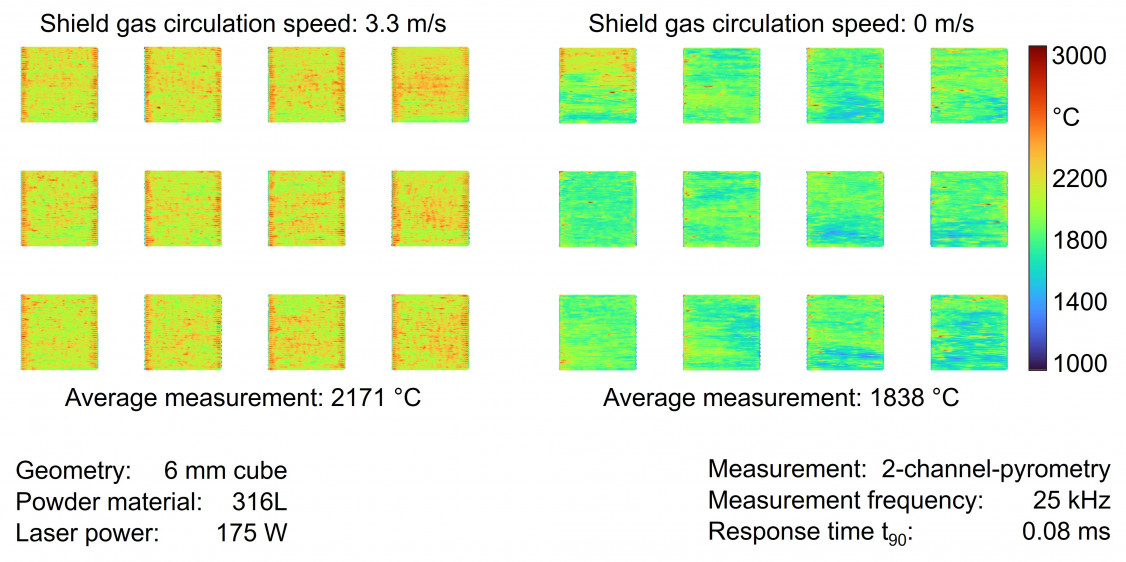

Monitoring of process influences To determine the possible applications of high-resolution temperature maps for monitoring process influences, the influence of shielding gas circulation on the process temperatures and the measurement was investigated. A reference set-up [4] was first used to investigate whether the temperature measurement is influenced by fumes. This can be the case if the measuring wavelength ranges used are absorbed to different degrees in the fume [5]. In the case of the powder material 316L and the measuring wavelength ranges used of 1.65 μm to 1.8 μm and 1.45 μm to 1.65 μm, it was shown that the measurement is not affected by fumes. In contrast, the process is strongly influenced by fumes, as also shown in other studies [6]. Figure 2 shows temperature maps of additively manufactured cubes that were produced with a high shielding gas circulation speed (3.3 m/s) and no circulation (0 m/s). The remaining parameters are identical for all components shown. It is clear that the process temperature is reduced by more than 300 °C if there is insufficient exhaust gas removal. In the case of 0 m/s, it can also be seen that this effect occurs successively with the first exposed component (top left), as the undissipated fumes also accumulate successively.

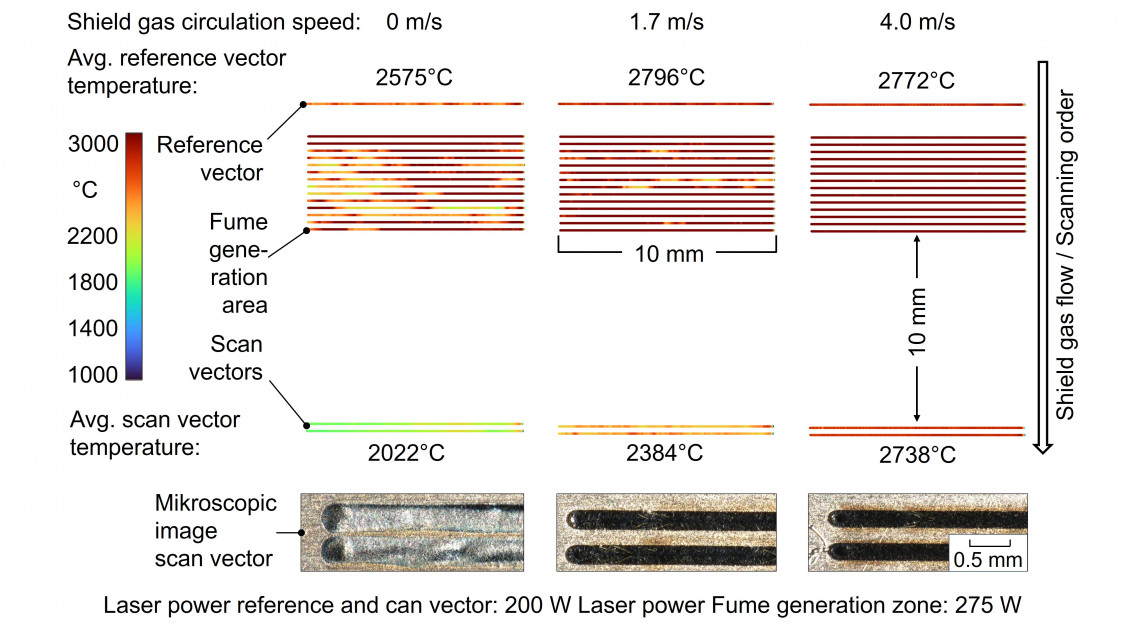

In order to investigate the influence of fume on the process in more detail, the influence of different shielding gas circulation speeds on the resulting process temperature and width was analysed. For this purpose, a process set-up was used in which a single reference vector is exposed first. Subsequently, fumes are generated by exposing a rectangular area at high power. Finally, scan vectors are exposed, which are influenced by the generated fum, Figure 3.

Without shielding gas circulation, strong influences of the undissipated fumes on the scan vectors and also on the reference vectors can be recognised. A clear reduction in the process temperature and widening of the weld seam can be seen. The main reason for this is the scattering of the laser light by fume particles, which results in a defocussing effect. As the circulation speed increases, the influence of smoke is reduced. At high circulation speeds (e.g. 4 m/s), the fume is sufficiently removed from the process zone, resulting in a uniform reference vector temperature, while the average scan vector temperature and melt pool width match the respective reference values.

Layer-by-layer process control

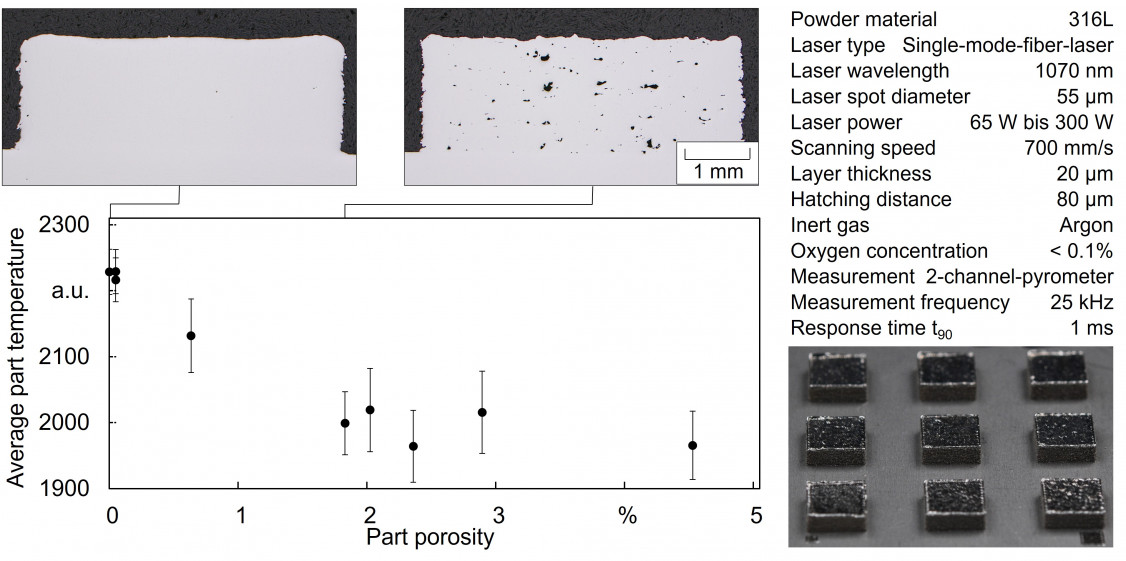

In order to be able to use the PBF-LB process for process control by means of high-resolution temperature maps, the correlation between the average process temperature and the component porosity was first investigated [7]. The aim was to determine a suitable target value/temperature range for laser powder bed fusion with 316L powder and a layer thickness of 20 µm, which ensures high part densities. Figure 4 shows the average process temperature as a function of the part porosity. In order to avoid the influence of different heat dissipation cross-sections on the temperature field, simple rectangular components were used. It becomes clear that the average temperature of components with low porosity is in the range of 2200 °C. Furthermore, it can be seen that in addition to the temperature, the standard deviation from the average process temperature is also an indicator of the quality of the process control. For example, parameter sets resulting in low porosity have low standard deviations from the average process temperature.

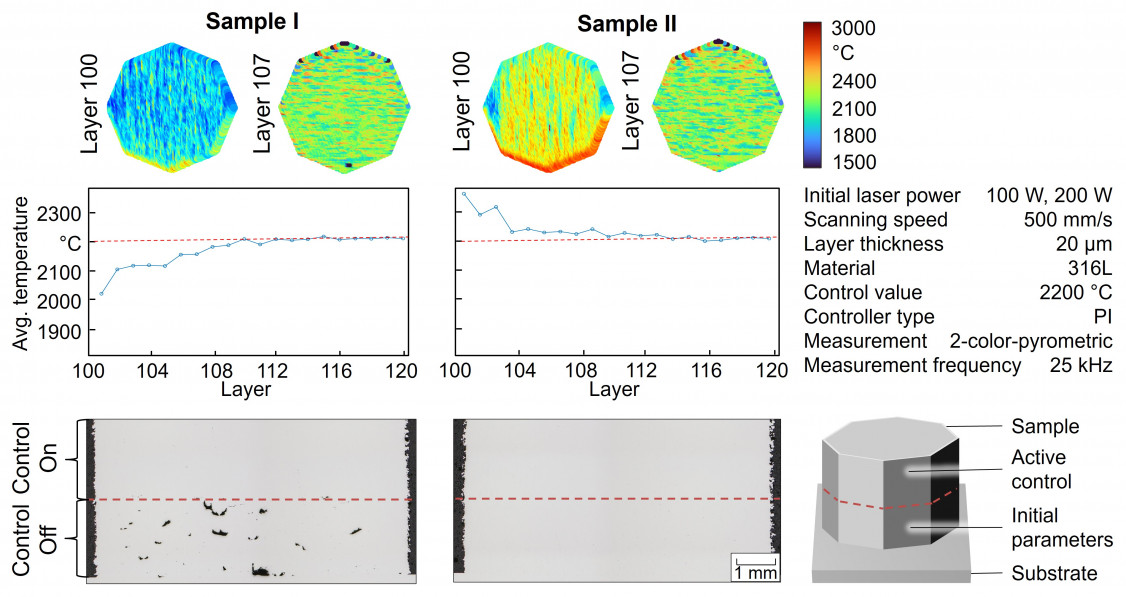

Taking the determined target temperature into account, Figure 5 shows the application of spatially resolved process control using two example components. These components were manufactured at the beginning, during the first 100 layers, with initial, insufficiently optimised parameters.

From layer 100, the control was switched on during the process sequence. Component 1, which exhibits too low a process temperature and increased porosity when using the initial parameter set, is raised to the target temperature by means of controlled laser power, resulting in an almost pore-free component. Similarly, component 2, which was produced with better optimised initial process parameters, shows irregularities in the temperature field during the first 100 layers. After activation of the process control, these irregularities are corrected and a uniform temperature field within the target value range is achieved.

4 Summary

A PBF-LB/M system was developed for spatially resolved temperature field-based process control, which can generate temperature maps using coaxial quotient pyrometer measurements. These high-resolution temperature maps can be used to monitor the process with regard to the expected part porosity and the quality of fume removal. It has been shown that homogeneous process temperatures and thus high component quality can be achieved without additional parameter optimisation by means of spatially resolved and layer-by-layer process control based on temperature maps.

(Source: Published in SCHWEISSEN UND SCHNEIDEN 11/25 DOI: https://doi.org/10.53192/SUS20251140)

Schlagworte

Additive ManufacturingAMLaser Powder Bed FusionLPBFPBF-LB/MWelding