The Swiss flow solutions provider received the German Innovation Award in the Excellence in Machines & Engineering category on May 13 in Berlin, Germany. The award honours products, projects and pioneering achievements that sustainably improve life through innovation and progress.

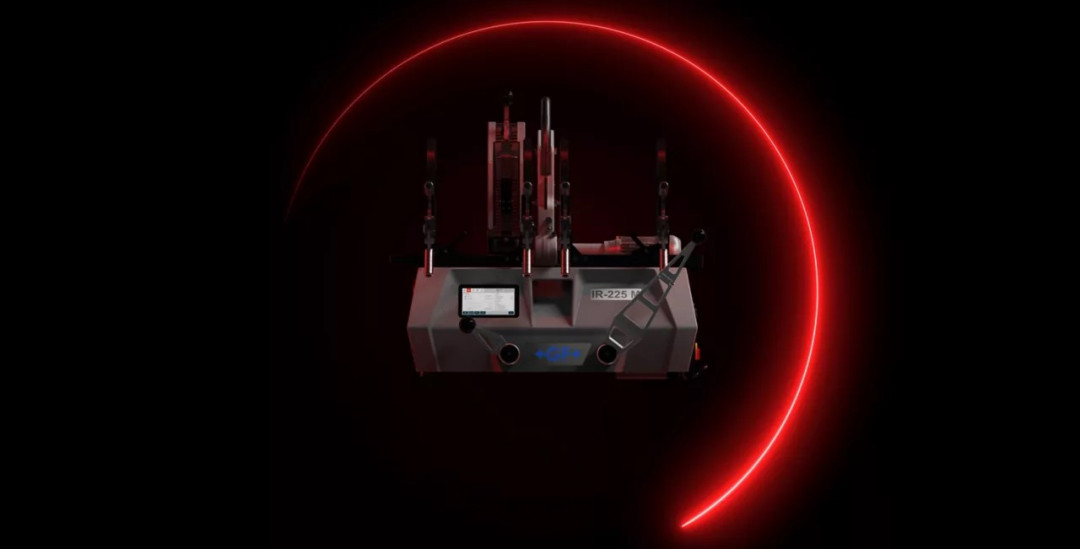

Building on the success of the IR-63 M, GF set out to further improve infrared pipe welds in industrial applications. Thanks to design improvements resulting from research and material knowledge, the IR-225 M enables shorter cooling times. At the same time, it has extended the range of weldable materials in the same application-oriented dimension range. Experts from the development team will unveiled the fusion machine in a webinar on June 4, 2025.

Bastian Lübke, Head of Jointing Solutions at GF, is proud of the achievement: “For over 30 years, we have continuously improved infrared fusion with an ever-faster process and a growing range of dimensions. Last year, the IR-63 M already made a big leap forward with its usability, connectivity and speed. As its big brother, the IR-225 M expands on these improvements with even more innovative features and increased efficiency. We look forward to presenting our next-generation fusion machine in detail next month.”

GF’s infrared fusion machines deliver contact-free welding of materials such as PVDF, ECTFE, PP-H, PP-n, PE100 and PVC-U. IR fusion technology is especially valuable in industries like chemical processing, microelectronics and water treatment, where long-lasting and reliable operation is essential. The machine-controlled process streamlines installation, minimizing steps and significantly reducing both preparation and cooling times.

(Source: Georg Fischer Piping Systems Ltd)

Schlagworte

AwardECTFEGerman Innovation AwardInfraredInnovationIR fusion technologyMade in GermanyManufacturingMaterial ProcessingPE100PP-HPP-nProcessingPVC-UPVDF