International

23.11.2024

Global Robot Density in Factories Doubled in Seven Years

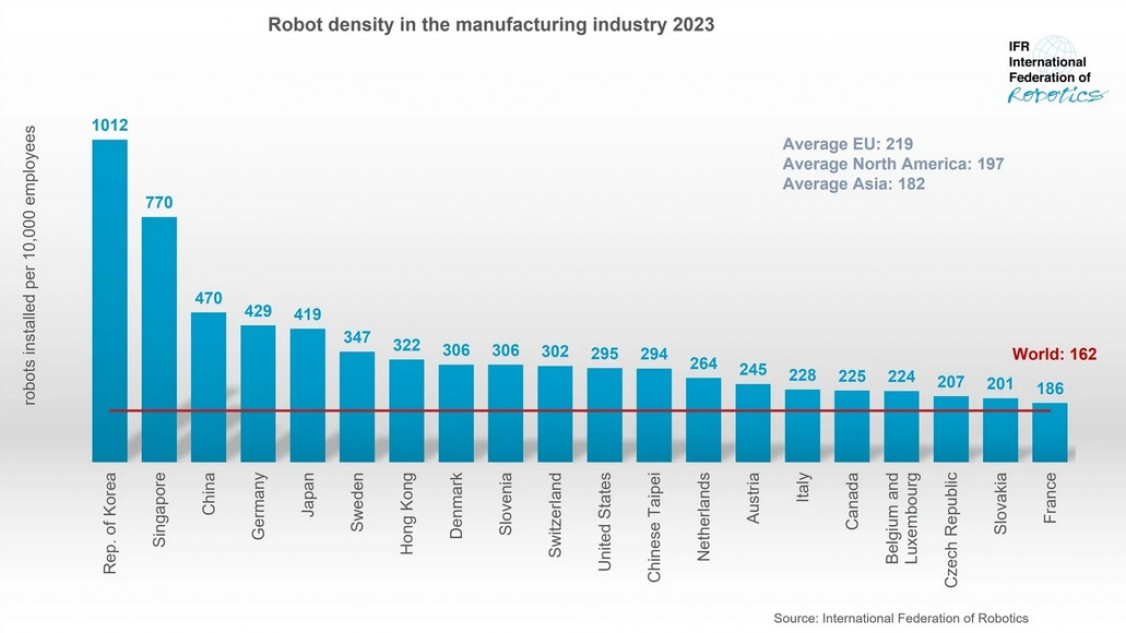

Robot adoption in factories around the world continues at high speed: The new global average robot density reaches a record 162 units per 10,000 employees in 2023 - more than double the number measured only seven years ago (74 units). This is according to the World Robotics 2024 report, presented by the International Federation of Robotics (IFR).

Robot density serves as a barometer to track the degree of automation adoption in the manufacturing industry around the world," says Takayuki Ito, President of the International Federation of Robotics. “This year's runner-up is China, which ranks third worldwide behind Korea and Singapore, but right up with Germany and Japan."

Robot density by region

- The European Union has a robot density of 219 units per 10,000 employees, an increase of 5.2 %, with Germany, Sweden, Denmark and Slovenia in the global top ten.

- North America´s robot density is 197 units per 10,000 employees – up 4,2 %. The United States ranks eleventh in the world among the most automated countries in the manufacturing industry.

- Asia has a robot density of 182 units per 10,000 persons employed in manufacturing – an increase of 7.6 %. The economies of Korea, Singapore, mainland China and Japan are among the top ten most automated countries.

Top countries

- The Republic of Korea is the world´s number one adopter of industrial robots with 1,012 robots per 10,000 employees. Robot density has increased by 5 % on average each year since 2018. With a world-renowned electronics industry and a strong automotive industry, the Korean economy relies on the two largest customers for industrial robots.

- Singapore follows with 770 robots per 10,000 employees. Singapore is a small country with a very low number of employees in the manufacturing industry, so it can reach a high Robot density also with a relatively small operational stock.

- China took third place in 2023, surpassing Germany and Japan. The country's push to the use of automation technology results in a high robot density of 470 robots per 10,000 employees (2022: 402 units). China only entered the top 10 in 2019. It has managed to double its robot density within four years.

- Germany ranks fourth with 429 robots per 10,000 employees. The robot density of Europe´s largest economy has grown by 5 % CAGR since 2018.

- Japan is in fifth place with 419 units. Robot density of the world´s predominant robot manufacturing country grew by 7% on average each year (2018-2023).

- Robot density in the United States reached 295 units in 2023. The country ranks eleventh in the world.

(Source: International Federation of Robotics Press Release)