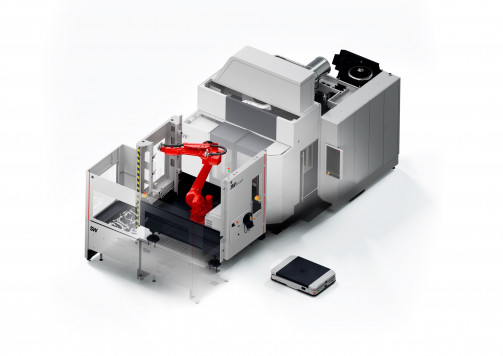

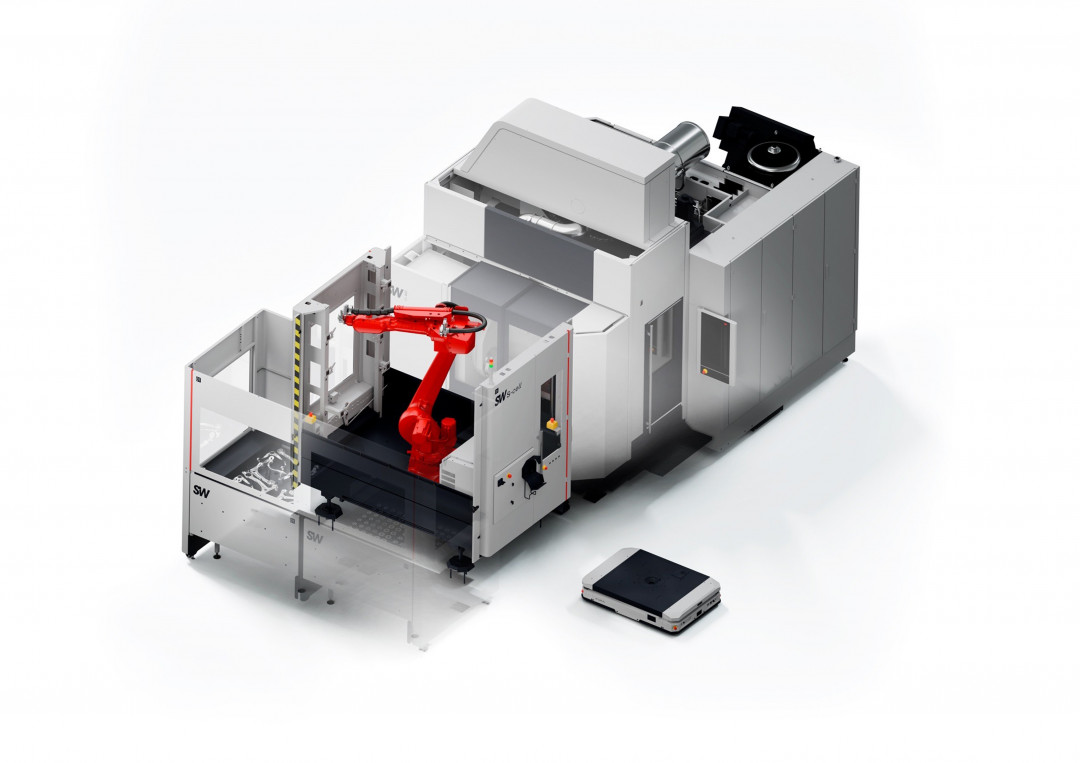

While classic production lines are designed for fixed processes, the Smart FMS enables flexible machining of different workpiece types and batch sizes without time-consuming changeovers. This results in an approach that addresses both economic requirements – such as higher utilization and shorter setup times – and ecological goals aimed at reducing material and energy consumption. With its three core technologies – the Sfix system, the S-cell mobile robot cell, and the pallet changing system – the Smart FMS enables the transition from isolated machine concepts to adaptive manufacturing systems that can be dynamically adapted to changing production conditions.

System for different workpiece variants and batch sizes

The Sfix system simplifies clamping of workpieces. Until now, each workpiece required an individual clamping device that had to be designed and stored – an expense that was particularly significant for small series with many variants. In the Sfix-cell, a robot automatically assembles the required clamping device from standardized components in just a few minutes. The basis for this is the patented Sfix plate, on which the elements are precisely positioned using the CAD model of the workpiece.

"Sfix makes the clamping process plannable and reproducible," explains Michael Kreuzberger, product manager at SW. "This significantly reduces setup and storage costs and increases process reliability – especially with frequently changing components." The modular system can replace up to 150 conventional clamping devices. This reduces material consumption and storage needs while enabling economical, resource-saving production across a wide range of batch sizes.

The pallet changing system – also a component of the Smart FMS – further automates the production process: It acts as an interface between the Sfix-cell and the machine tool, enabling the quick and safe exchange of workpiece pallets without manual intervention. The pallet changing system can be moved flexibly via a floor axis or positioned by an autonomous mobile robot (AMR).

Mobile automation for flexible manufacturing environments

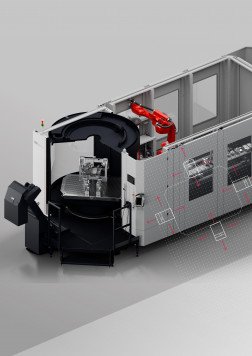

The S-cell system complements the Smart FMS with an intelligent automation solution. It enables flexible material flow between machining, cleaning, or assembly stations without rigid interlinking. The S-cell, a mobile platform with a permanently installed industrial robot, moves autonomously through the production facility via a driverless transport system. It docks precisely at the respective station, takes over the loading and unloading of workpieces and moves on to the next task once the process is complete. The cell independently recognizes the type of station it is connected to and automatically adapts its processes. At the same time, the machines remain freely accessible, for example for maintenance or setup processes.

In combination with the orchestration software SmartFlow, the system ensures efficiency and utilization of the entire plant. Thanks to AI-supported planning, it adapts dynamically and flexibly to changes in the production process – without any manual intervention. "This solution is highly cost-effective, as it enables step-by-step investment, high component reusability and short amortization times," says Michael Kreuzberger, summarizing the advantages. "Companies can implement the system gradually and expand it as needed, as it can be easily networked with SW machines and systems from other manufacturers thanks to open interfaces."

(Source: Schwäbische Werkzeugmaschinen GmbH)

Schlagworte

AMRAutomated Mobile RobotAutomationClampingManufacturingRobotRoboticsRobotsSoftwareSustainabilitySystem Solution