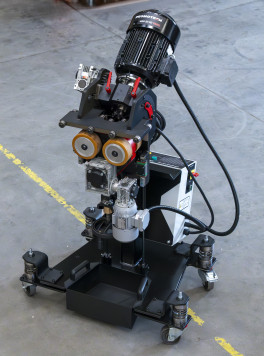

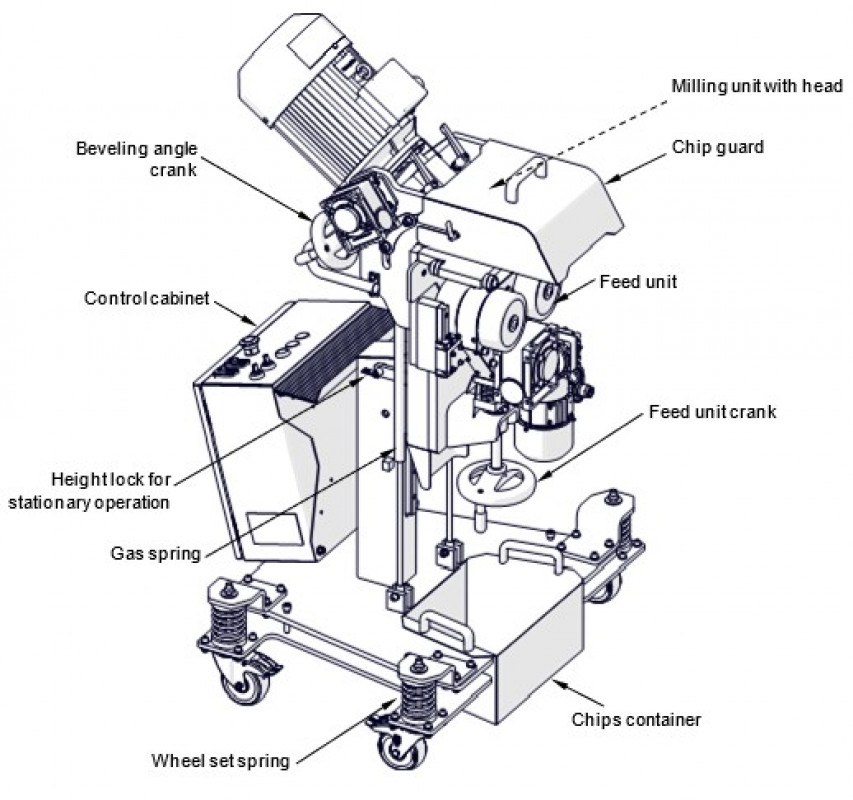

The Promotech ABM-50 DD Vario is a self-propelled, heavy-duty bevelling machine engineered to produce bevels up to 50 mm wide – without thermal distortion or a heat-affected zone (HAZ). The ABM-50 DD Vario delivers accurate, efficient and repeatable results, whether used for preparing structural elements in large-scale fabrication projects or for fine-tuning weld joints in a workshop setting.

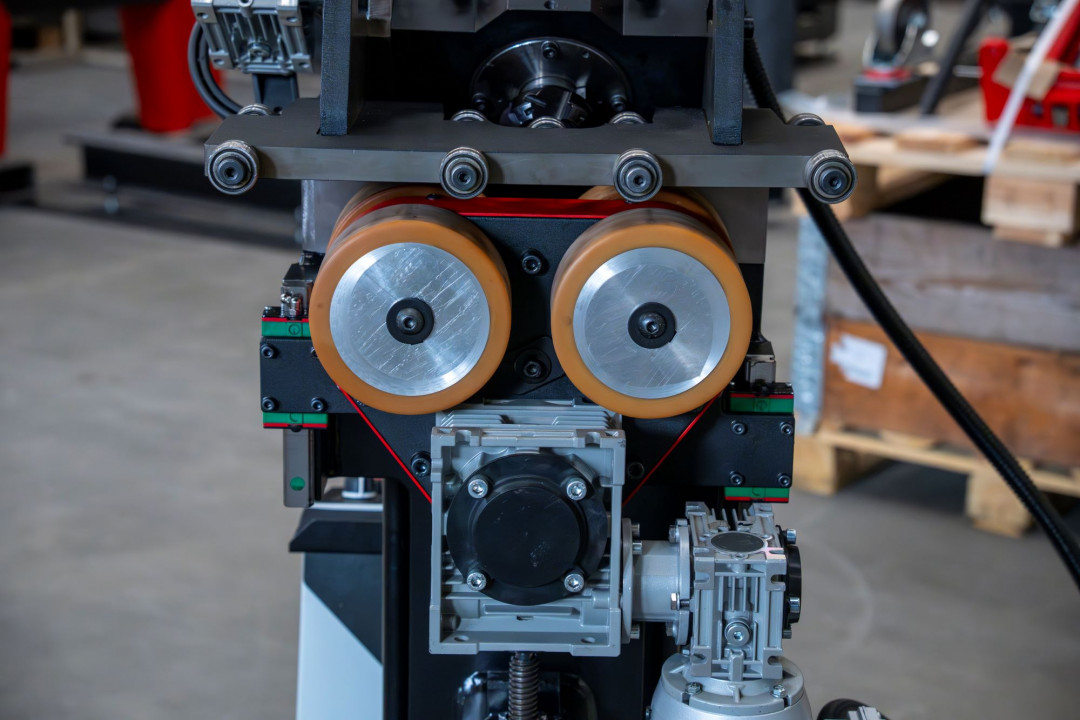

Auto-feed drive system allows ABM-50 DD Vario to travel along the workpiece at speeds of up to 1.2 m/min, reducing operator effort and delivering consistent results across long plate lengths. In addition, the spring-loaded castors on the trolley compensate for surface irregularities or misalignment between the plate and floor, ensuring smooth, steady operation during the bevelling process.

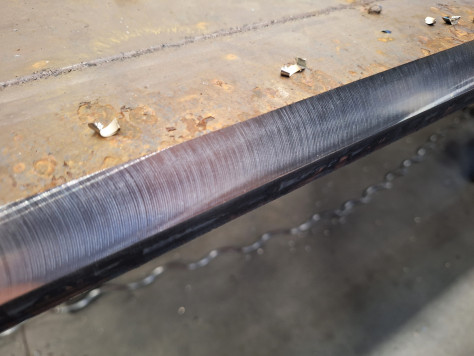

Clean, cold bevels

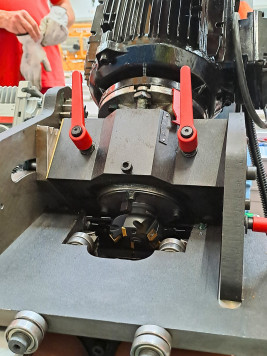

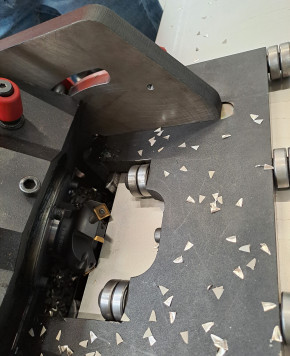

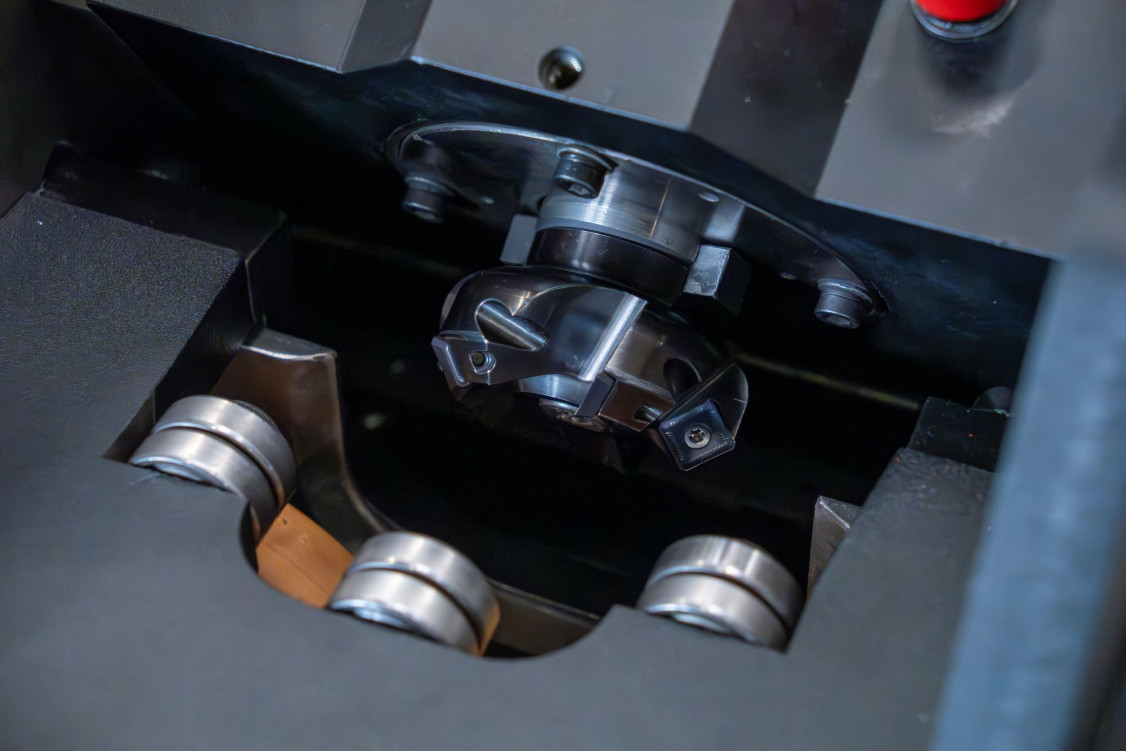

Unlike thermal cutting, the ABM-50 DD Vario uses a high-performance rotary milling head with indexable cutting inserts to create clean, cold bevels. This mechanical process prevents the formation of heat-affected zones (HAZ), maintaining the structural integrity and mechanical properties of the base metal.

The milling head features five four-edged indexable inserts, which can be rotated to maximize tool lifespan and reduce downtime. Various insert types are available, optimized for specific materials, guaranteeing stable operation and a fine surface finish across diverse steel categories.

Adjustable feed and spindle speed

With variable spindle speed ranging from 500 to 1450 rpm and adjustable feed rate, ABM-50 DD Vario allows for easy cutting parameters optimization to suit various steel grades. For operations focused solely on carbon steel, a fixed-speed version – the ABM-50 DD beveller – is also offered. Spindle rotational speed (without load) for ABM-50 DD is fixed at 1450 rpm (50 Hz) or 1750 rpm (60 Hz). ABM-50 DD is a cost-effective alternative when variable cutting parameters are not required.

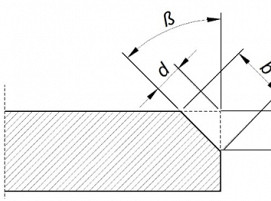

Continuous bevel angle adjustment

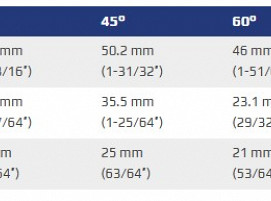

The ABM-50 DD Vario offers continuous, stepless bevel angle adjustment from 15° to 70°, enabling users to tailor the bevel geometry according to project requirements. The resulting bevel shape depends on the selected angle (β), bevel height (h), and depth (d).

Real-Time load monitoring with LED indicators

A built-in LED load monitoring system uses green, yellow, and red lights to show the current load level, helping prevent motor overload and protect the milling system under varying load conditions. By combining cold milling technology with adjustable operating parameters and compatibility with various materials, ABM-50 DD Vario presents a highly efficient, reliable alternative to manual or thermal edge preparation—cutting down on time, labour, and cost.

Key performance specifications:

- Self-propelled operation with auto-feed:

- Speed up to 1.2 m/min

- Stepless bevel angle adjustment: 15°–70°

- Continuously adjustable bevel width: up to 50 mm at 45°

- Plate thickness range: 8–80 mm

- Height adjustment: 840–1040 mm from floor level (for top-edge bevelling)

- LED overload monitoring system

- Milling head equipped with 5 pcs of 4-sided indexable cutting inserts

- Stationary operation for machining small workpieces

(Source: Promotech)

Schlagworte

BevellerBevellingCuttingMillingRotary CutterRotary MillingWelding