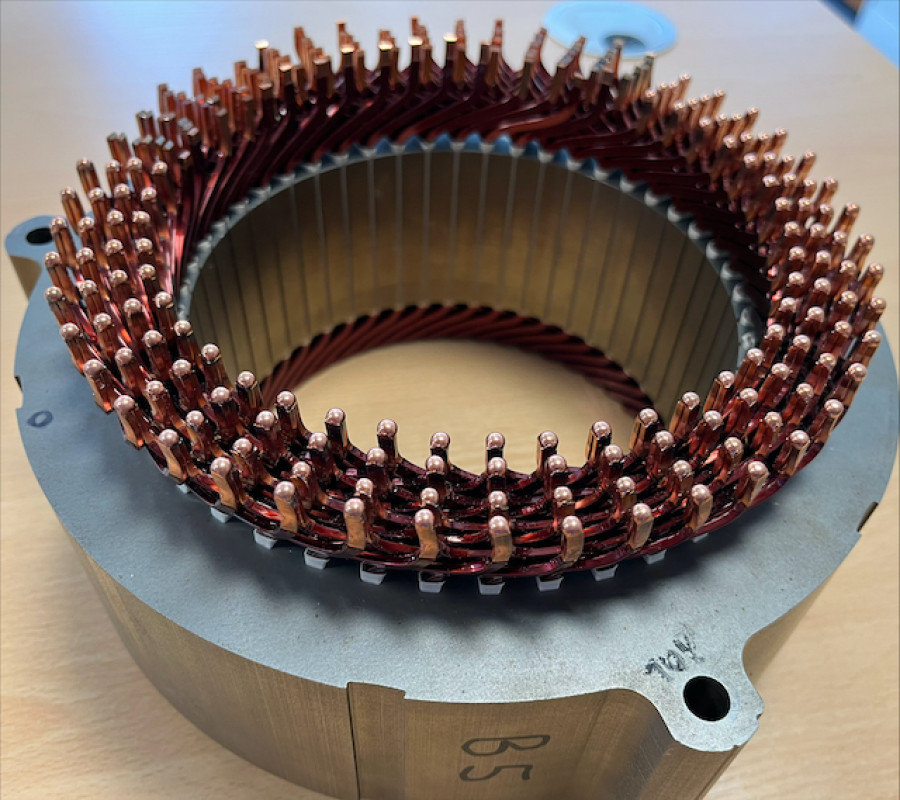

Cambridge Vacuum Engineering (CVE) and Ford have completed a £430,000 Innovate UK-funded EB-eDrive project – proving that the manufacture of electric motor stators can be improved by utilising advanced electron beam welding. As part of Innovate UK’s Driving the Electric Revolution Challenge, CVE and Ford demonstrated that electron beam welding can enhance the quality of electric motor stators and the repeatability of associated production processes, paving the way for widespread industrialisation of the technology.

Findings from the project could help boost the UK’s production of electric vehicles (EV) and support the nation’s net-zero carbon goals. Demand for electric vehicles is growing. However, several barriers to widespread adoption remain – mainly around pricing. The production of motor stators is one factor, with components requiring precise engineering to optimise performance, efficiency and durability.

Using CVE’s proprietary technology, the two partners showed that electron beam welding is an effective and reliable joining method for copper hairpin stators and that it:

- Does not require any preparation of the hairpins, such as trimming, as the electron beam does not suffer from reflectivity issues as infrared lasers do.

- Produces welds that are strong, displaying – on average – a tensile strength six times the minimum limit.

- Allows easy outgassing thanks to the use of a vacuum environment, leading to completely pore-free welds in oxygen-free (OF) copper.

Bob Nicolson, CEO of CVE, said: “As automotive brands look to deliver higher performance, longer range electric vehicles at lower costs, it’s clear that electron beam welding has a major role to play. We are seeing the same story play out in other industries – for example in the energy sector where electron beam welding can enhance the production of wind turbine monopiles and nuclear pressure vessels. We are grateful to Innovate UK for this funding. Projects like this open the door for the commercialisation of advanced manufacturing technologies and will help the UK remain at the forefront of electric vehicle production. We look forward to working with Ford moving forwards.”

Lee Turner, Director of EU Powertrain Manufacturing Engineering at Ford said: “The Ford Powertrain Manufacturing Engineering team are continuously engaged in work to deliver improvements in the quality and efficiency of motor (stator) hairpin weld processes. Our developments of laser parameters set-up and repair processes have been industry leading but we now see clear opportunity to make significant further progress through the potential adoption of Electron Beam Welding. We are grateful to have collaboration partners like CVE to work with as we investigate routes to full scale industrialisation of this technology. Their unparalleled knowledge, experience and expertise are invaluable in the delivery of the project.”

Venn Chesterton, Deputy Director, Driving the Electric Revolution, at Innovate UK said: “This project has brought together multiple actors within the UK advanced electronic manufacturing ecosystem to develop a truly world class technology, which is going to be used in manufactured at scale in the UK and around the globe. This is just one example of the numerous projects backed by Innovate UK which are ensuring that UK manufacturing supply chains will prosper from electrification.”

(Source: Cambridge Vacuum Engineering)

Schlagworte

AutomotiveElectric VehiclesElectron Beam WeldingEVMobilityNet ZeroStatorsWeldWelding