Reliable fiber-PIC connections

Researchers at Fraunhofer IZM have developed a laser welding process that works without adhesives to connect Photonic Integrated Circuits (PICs) with optical fibers. Uniquely, the technology can be used at cryogenic temperatures down to a mere four Kelvin, 269.15 °C below zero. The direct quartz-to-quartz connections created by the technology promise more reliable, faster and cheaper fiber-PIC-connections that will revolutionize quantum technology applications.

Low temperatures are needed to observe quantum effects in action. These can have a real impact on the quality of life, as big-data use cases like personalized medicine or many other medical data applications can only be handled by quantum computing. Lots of attention and effort is currently going into the development of cryogenic quantum computing systems. Quantum technology systems with implemented PIC-based modules promise a more compact solution for safe communication and connections in quantum computing, but photonic systems like these need reliable glass fiber connections. The technology will benefit other areas from biophotonics to sensor technology.

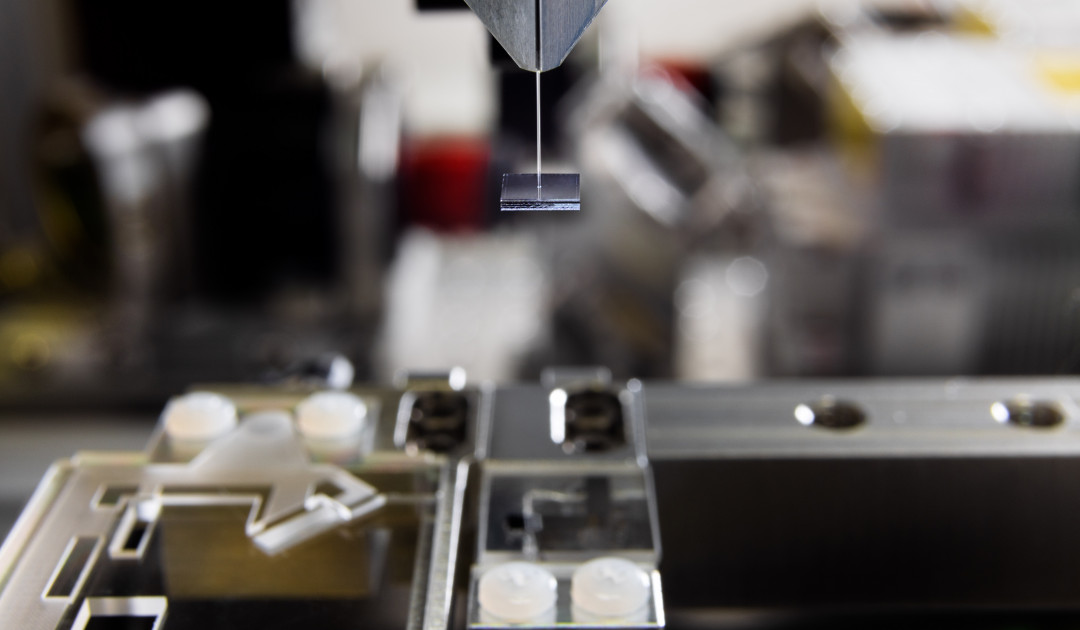

As part of the QWeld project, researchers at Fraunhofer IZM have come up with a novel laser welding technology for vertical optical connections. It uses the prototype PICWeld processing unit assembled and installed at the Institute during a previous research project. The facilities made it possible for the first time to form a direct laser-welded connection between glass fiber and silica-glass PICs, which is more durable and thermally robust than conventional adhesive connections. The work on the QWeld project is focused on taking this connection technology and bringing it over to applications in cryogenic environments. It employs PICs that were made with a standard CMOS process, but designed with one special feature: a silicon dioxide (SiO2) top layer that is needed for glass-on-glass laser welding. Uniquely, the fiber is connected vertically to the PIC, usually at a specific inclination. During welding, the laser hits the contact point between the PIC and the glass fiber on both sides and creates a material bond between both in only a few seconds, promising a major acceleration of the manufacturing process. Making this possible under the new conditions set for the project, primarily the combination of SiO2 materials and the exacting standards in terms of high-precision alignment meant that the entire process and the production system had to be refined and redeveloped, including the addition of a local preheater, added alignment features, and new sensors. The welded bond is durable and the process is reproducible and can be automated, making it possible to create PICs in the large numbers needed for quantum systems.

Dr. Alethea Vanessa Zamora Gómez, researcher at Fraunhofer IZM and coordinator of the project, celebrates the successful application of the technology for quantum photonics: „The novel laser welding process uses a CO2 laser to heat up a specific part of thePIC’s SiO2 layer to minimize the temperature difference between the fiber and the PIC during the actual welding. The innovative preheater technology is likely to solve all of the current challenge we encounter when bonding fibers to PICs at cryogenic temperatures. Since we can use CO2 lasers, the process can be automated, making it inexpensive and reliable and ultimately attractive for industrial use. “Dr. Zamora Gómez and process developer Marco Queisser have accomplished what they set out to do in the project: To find a new laser welding technology for fiber-to-PIC connections that will pave the way for new cooperation opportunities in cryotechnology and quantum PICs. They also expect more applications in biophotonics, sensor technology, and high-performance lasers.

The QWeld project was fully funded by the „Preliminary Research Projects for Photonics and Quantum Technology ‘Initiative of the Federal Ministry of Education and Research’”. As part of the „Quantum Technology – From the Fundamentals to the Market“ program, QWeld ran from 1 August 2022 to 31 December 2024, coordinated by Dr. Alethea Vanessa Zamora Gómez at Fraunhofer IZM.

(Source: Fraunhofer IZM Press Release)

Schlagworte

LaserLaser Beam WeldingWelding