New sales director joins Blackbird management team

Blackbird Robotersysteme GmbH, manufacturer of system solutions for remote laser welding, is growing its leadership team and creating a new area for business field development. Benjamin Bopp will be in charge of sales starting in April. Longstanding sales director Thibault Bautze-Scherff will focus on targeting new business fields in the future. This puts him in a leading role in terms of the company’s strategic growth. By making this move, the mid-sized company is taking another step forward with its development strategy while also ensuring that intensive customer care and the proactive evolution of its range of products and services continue.

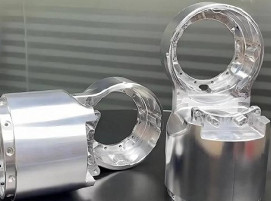

Blackbird has been a partner to the automotive industry and other industrial sectors for years. Since 2015, the company has also been internationally recognized as a solution provider in the growth market of electric mobility, for example for batteries and electric motors production. Its global customers receive support worldwide, including through the company’s cooperation with ABICOR BINZEL.

The company, based in Garching near Munich, is repositioning itself to meet the growing requirements of its diverse customer base and to focus more on general future trends. To uphold that same high standard and expand its market position, Blackbird is adding a new business development department to its organization. Thibault Bautze-Scherff (39), the experienced prior sales director, took over as head of the new unit on April 1, 2024. Together with his team he focuses on future technologies, previously unexplored areas of application for laser processing, and expanding partnerships with research institutions and associations to support the company’s medium-term growth.

“Lasers as tools are viewed as one of the key production methods of the future, especially in conjunction with concepts like artificial intelligence and smart manufacturing. Blackbird plans to continue blazing a trail into the future for its customers and business partners,” explains Thibault Bautze-Scherff.

New head of sales with solid laser technology background

Benjamin Bopp (43) is stepping in to fill the gap in the role of global sales manager starting in April. From his previous work as an application engineer specializing in laser welding, Bopp brings a wealth of professional expertise in technical consultancy. Besides this he gained more than 15 years of experience in international sales from his former roles. One of the new manager’s key partners is the company’s subsidiary Blackbird Shanghai, which has been serving companies in the fast-paced Chinese market locally since the start of the electric mobility transition. There are also several joint customer projects within the sales and service partnership with ABICOR BINZEL, which Bopp is now also responsible for managing. “Decision-making channels within the electric mobility sector are much more complex than in traditional automotive manufacturing. Coupled with the increasing demands on laser system technology, we aim to offer our customers the perfect tools for their joining processes. Quality is crucial here, but that’s not all. It’s also about the flexibility in providing customer support,” Bopp says.

The boom in electric mobility and the rapid rise of new manufacturers have made the joining technology landscape and the variety of systems for process monitoring even more impenetrable than before. “At Blackbird, our goal is to provide technologically superior system solutions in competitive markets, combined with the user-friendliness customers have come to expect from us. This requires ongoing dialogue with users so we can learn from their needs. The new constellation, which consists of a strong sales team and dedicated business development, will allow us to both provide in-depth customer care and identify the requirements of tomorrow faster. This enables us to set the course for the future together with our customers,” comments Karl Christian Messer, CEO of Blackbird, the change.

(Source: Blackbird Press Release)