You will find the company at the fair in Hall 6, Stand 6A26.

You will find the company at the fair in Hall 6, Stand 6A26.

![SCHWEISSEN & SCHNEIDEN 2025 [EN]](/images/frontend/journals/dvs-sus_sm.png)

Laser processes with dynamic beam shaping create stable joints even in challenging material combinations. Recent applications demonstrate how to eliminate filler materials while improving quality, energy efficiency and production logic. Fraunhofer Institute for Material and Beam Technology IWS will present laser welding solutions at the trade fair SCHWEISSEN & SCHNEIDEN 2025 (Essen, Germany, September 15 through 19) that expand both design freedom and economic potential. The focus is on intelligently guided beam processes that operate without filler wire and can be transferred into real production scenarios. Industries already applying the technology include lightweight structures for e-mobility, aerospace tanks, and load-bearing components in heavy steel construction.

Several current development projects rely on laser-based joining. A precisely controlled beam actively influences melt behavior, eliminating the need for filler wire. “We demonstrate that even the most demanding welding tasks – such as joining of difficult-to-weld material alloys or welding of heavy sections – can be performed robustly and productively with less energy, material and rework,” said Dr. Axel Jahn, Head of the Joining Department at Fraunhofer IWS. “The combination of high-frequency scanner technology, flexible power modulation and our open system control enables design options and application perspectives that conventional arc welding cannot provide.”

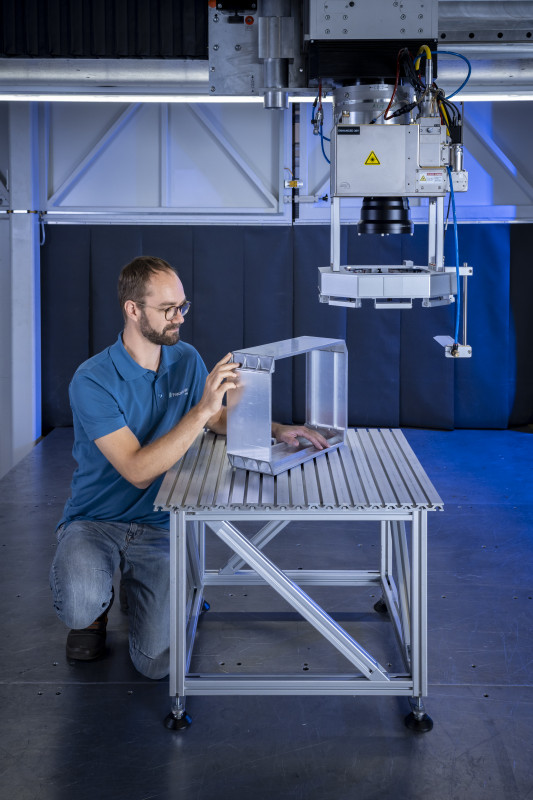

Aluminium battery housing: crack-free, pore-minimized, without wire

In the EU project Albatross, Fraunhofer IWS developed a laser-fabricated battery housing for electric vehicles and successfully demonstrated it at full component scale. The lightweight design combines aluminium extrusion profiles with die-cast aluminum parts, featuring walls up to five millimeters in thickness.

Conventional approaches reach physical limits with this pairing: die cast tends to form pores, while aluminium extrusion alloys of the 6000 series are prone to hot cracking. “Our solution relies on targeted oscillation of the laser beam, which moves the melt pool, reduces pores and produces metallurgically stable welds,” Jahn explained. “This allows us to generate high-quality aluminium welds without the filler material usually required.”

The housing has already been integrated and tested in a real vehicle model. Within the Fraunhofer lead project FutureCarProduction, the technology is now being advanced for secondary aluminium and cast-to-cast joints, alongside a sustainability assessment.

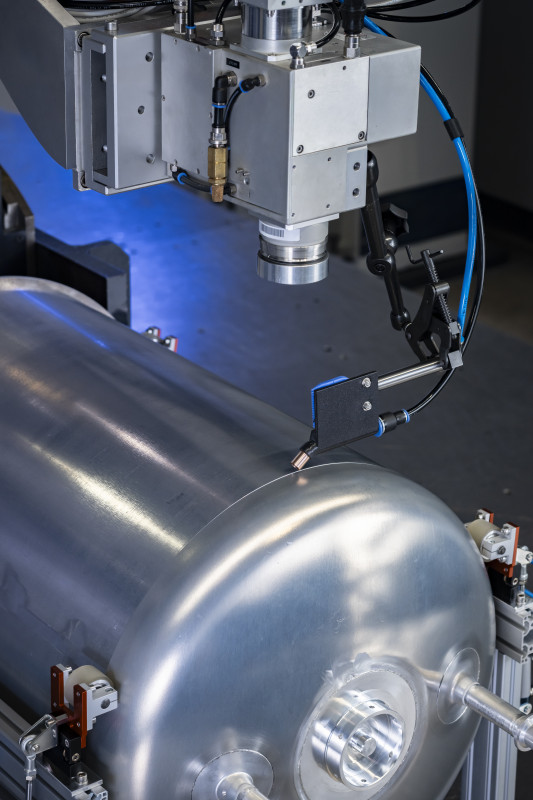

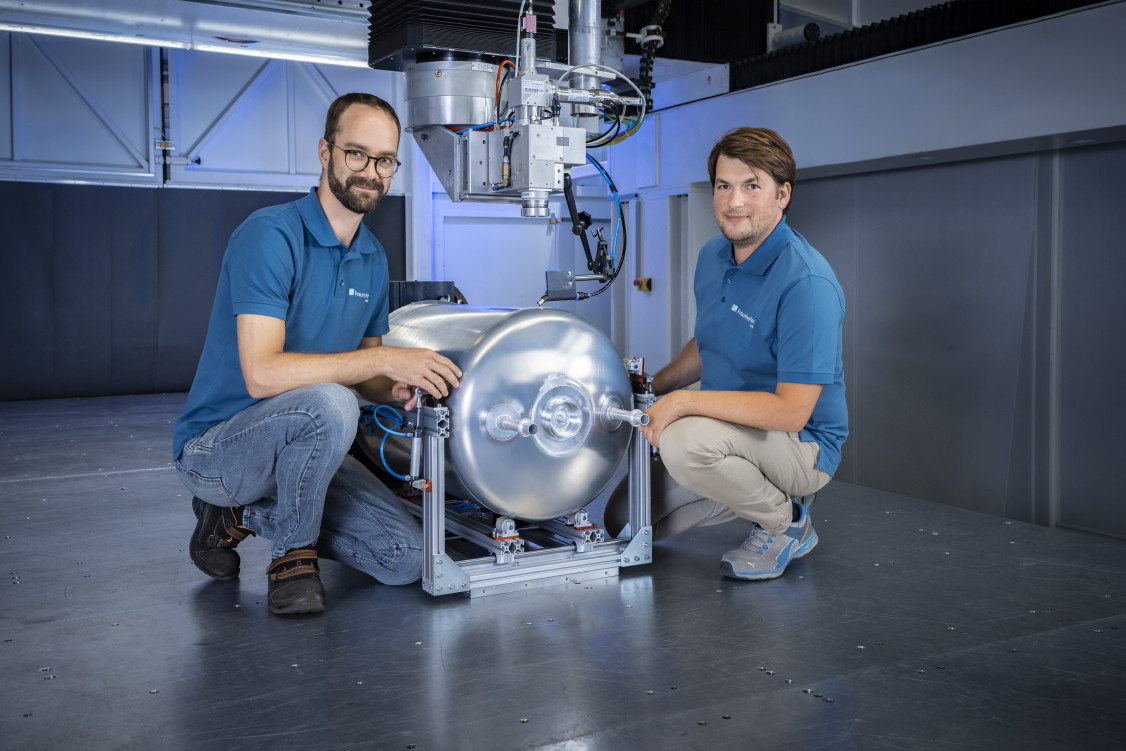

3D tank bottom: crack-free welds for demanding conditions

For aerospace applications, Fraunhofer IWS has developed a laser welding process with dynamic beam shaping to produce closed tank structures from high-strength 2000-series aluminum alloys. Since these alloys tend to form hot cracks, conventional welding typically requires the use of filler wire to adjust the alloy composition. In contrast, the new laser process operates without filler material and achieves stable, low-heat welding even on three-dimensional contours. “The process is ideal for closing rotationally symmetric containers and is also under study for pipe welding,” Jahn said. “It delivers tight, mechanically strong joints with minimal distortion and high seam strength.”

The demonstrator is being developed within an aviation project funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK). In parallel, Fraunhofer IWS is testing friction stir welding (FSW) for sheets and electromagnetic pulse welding (EMP) for hybrid pipe joints.

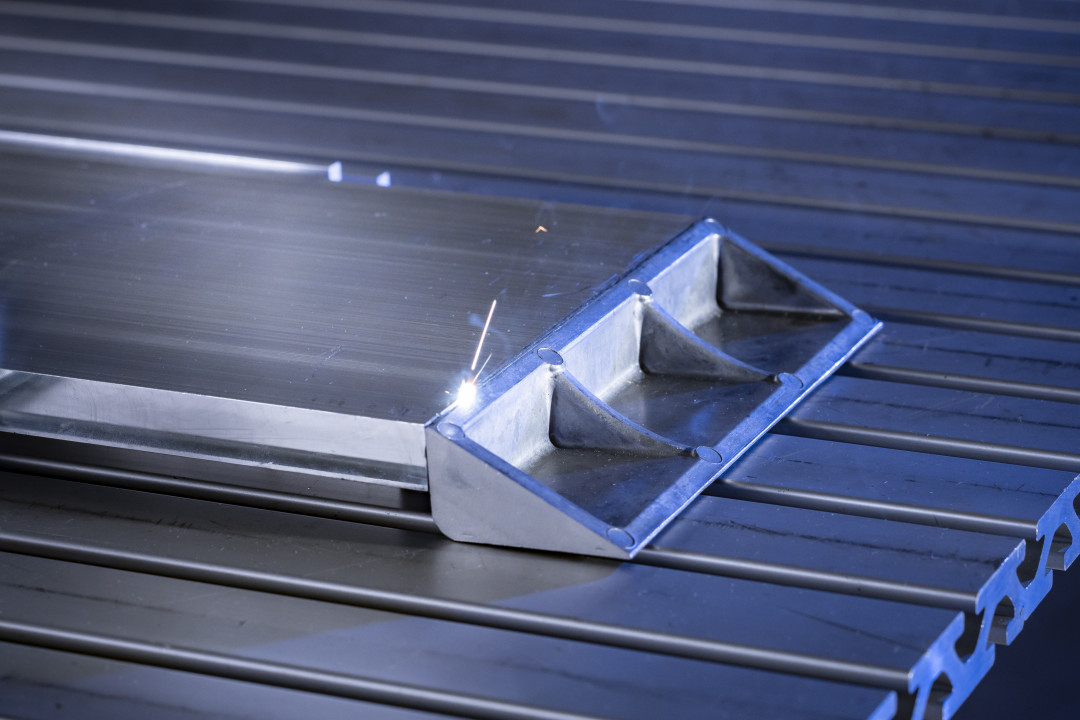

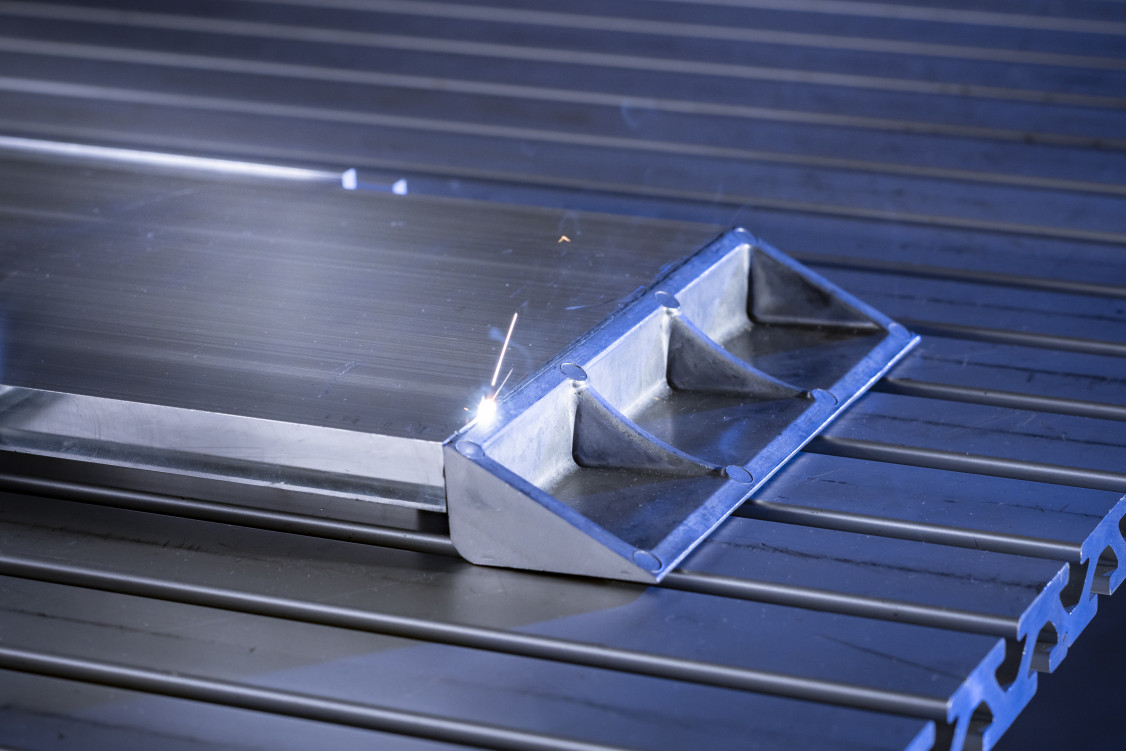

Crane boom: productivity boost for steel construction

Manufacturers of large steel structures now have a new option for joining thick profiles with wall thicknesses over 20 millimeters. Fraunhofer IWS demonstrated this on a four-meter-long crane boom. The process uses high-performance multilayer welding in a single clamping with up to 24 kilowatts of laser power. V-groove preparation has been optimized to opening angles below five degrees. “As a result, we reduce weld volume, save up to 90 % filler material and largely eliminate distortion,” Jahn noted. “Straightening large assemblies – often an energy-intensive manual step – becomes unnecessary in many cases.”

The project was funded through SAB and aims to transfer into bridge building, wind energy and shipbuilding. Initial industrial feedback confirms strong interest in integrating the technology into existing production lines.

(Source: Fraunhofer IWS)

Schlagworte

AerospaceConsumablesE-MobilityEventFairFiller MaterialsHeavy Steel ConstructionInstituteJointsLaser Beam WeldingLaser ProcessLaser-Based JointsShipbuildingTrade FairWeldWeldingWind EnergyWire