The SKZ Plastics Centre, together with its industry partners Reinhausen Power Composites and PS Werkzeuge Vorrichtungen Metallbearbeitung, has launched a new research project to develop innovative materials for high-voltage insulators. The aim is to develop a high-performance liquid silicone material that combines excellent dielectric and mechanical properties with cost-effective processability.

SKZ launches new research project

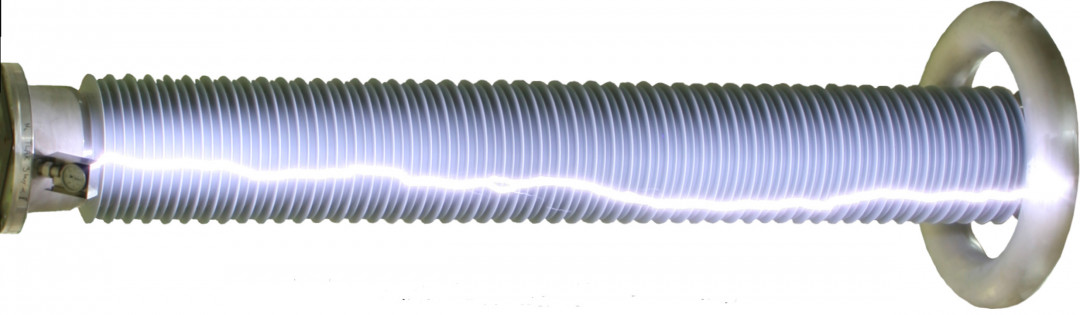

Numerous plastics are used in energy infrastructure – such as GRP semi-finished products for tap changers, rod insulators and hollow insulators, as well as silicone shielding and cable sheathing. The requirements for these materials are high: depending on the application, they must guarantee tightness, insulation or conductivity, weather resistance and durability under demanding conditions – while keeping costs low.

As part of the project funded by the Bavarian Energy Research Programme New Materials, novel liquid silicone materials are being developed for use in high-voltage insulators in outdoor applications. The project will run through September 2027. "With this project, we want to make an important contribution to security of supply and strengthen the future viability of materials in energy technology,’" emphasises project manager Thomas Zimmermann, group leader for networked materials at SKZ. The liquid silicones under development will be used in modern composite insulators, making them more durable and efficient.

Innovative materials for a secure energy supply

The material innovations planned in the project offer a wide range of advantages: by combining functionalised fillers with specially selected liquid silicone types, high-voltage insulators with significantly improved mechanical and dielectric properties can be manufactured – with reduced material usage and energy-efficient, reliable processing. Another advantage is an integrated self-cleaning effect that extends the service life of the products, especially under real environmental conditions in outdoor operation.

(Source: FSKZ e. V.)

Schlagworte

CompositesInsulatorJoining PlasticsProjectResearchSilicone