Replique, the platform for industrial on-demand manufacturing, has announced the opening of a new Italian subsidiary to further strengthen its ability to serve its growing European customer base. Located in Milan, Replique Srl will serve as an additional base from which the company can deploy its range of manufacturing technologies – including 3D printing, CNC and injection molding – to address customers’ production challenges.

Expanding International Presence

“The foundation of Replique Srl is a strategic milestone in strengthening our platform’s position on a global stage,” says Henrike Wonneberger, Co-Founder and COO of Replique. “With this step, we’re deepening our connection to the Italian market and enhancing our ability to support our customers in the region in realizing spare parts and series applications quickly and cost-efficiently.” Renato Marelli, Technical Sales Manager at Replique, from the company’s new office in Italy, says: “Italy’s rich industrial heritage and energy for innovation make this region a truly exciting frontier. By establishing our local presence, we strategically support Italian companies in bringing innovative manufacturing solutions to life.”

Growth in Qualified Series Production

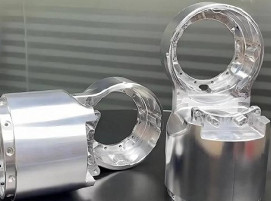

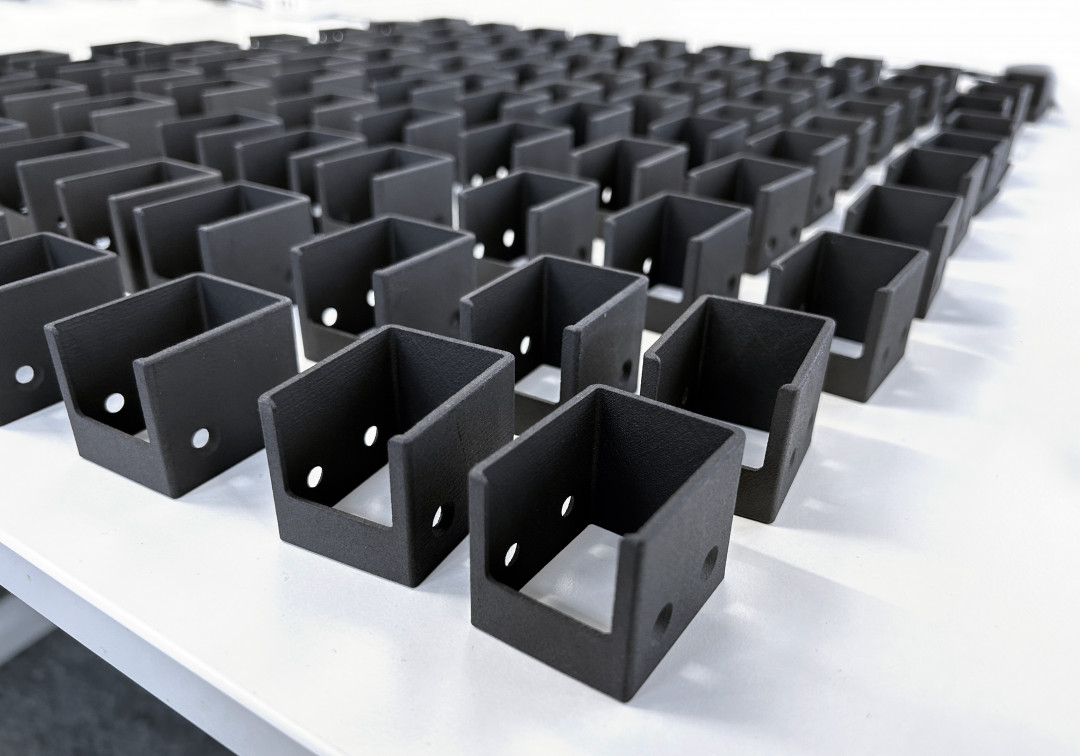

With an average of around 100 parts per order the platform now delivers regularly to diverse industries, from rail and mechanical engineering to pharma and healthcare. Series applications already account for 65 % of the business, alongside engineering services and one-off parts. Replique’s network of qualified partners now numbers over 350 worldwide and covers all key manufacturing technologies – from 3D printing and CNC machining to casting, forging, and injection molding.

Formnext 2025

At Formnext 2025 (Hall 12.1, Booth B95), Replique will present its platform, covering everything from engineering services and secure digital storage to decentralized, quality-assured production.

(Source: Replique)

Schlagworte

3D-PrintingAdditive ManufacturingAMCNCFormnextSeries Production