Laser-based infrared welding

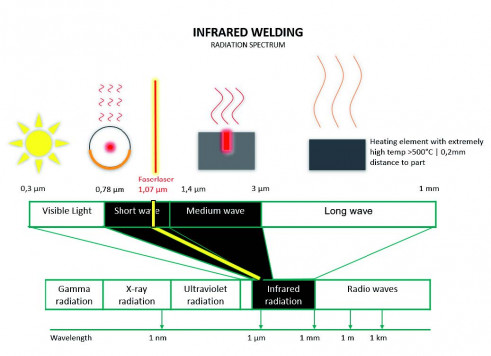

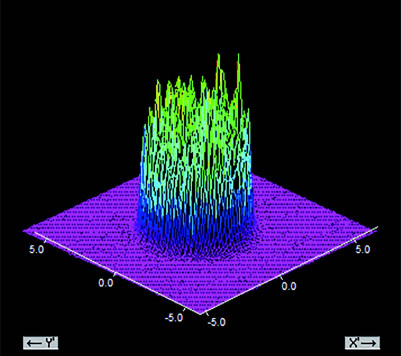

The laser-based infrared welding process further developed by bielomatik differs primarily in the energy source for infrared radiation. Instead of expensive and sensitive infrared tube radiators or metal foil ribbon emitters, a commercially available fiber laser system is used. This system operates in the infrared wave-length range of 1070 nm, Fig. 1. The fiber laser provides a top-hat beam profile, which is ideal for efficiently plasticizing welding ribs. Key technical advantages of laser-based infrared welding:

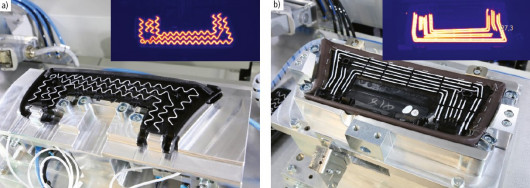

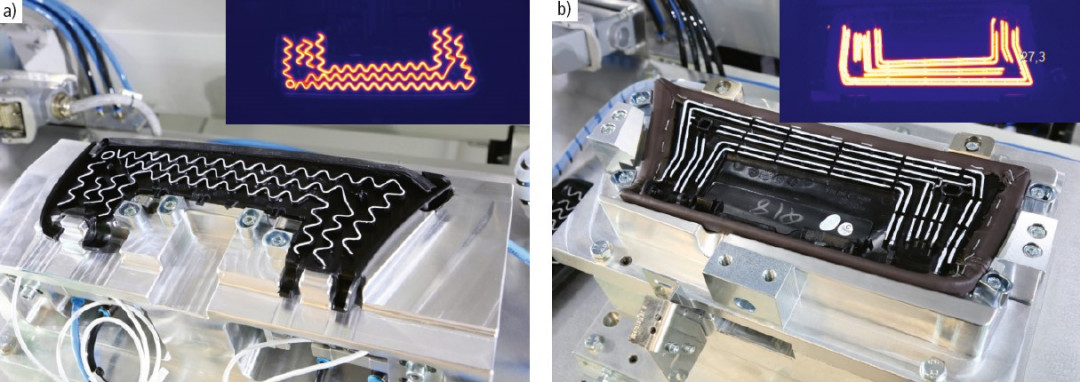

- Maximum flexibility: Using a laser source and a scanner, energy can be transferred almost simultaneously to any geometry.

- Reduced investment costs: Tool-investment is reduced by up to 70 %, as the laser-scanner unit serves as a programmable IR emitter that needs to be procured only once.

- Increased precision: The laser beam enables highly precise and localized heat input. Complex areas such as T-joints or ring welds can be welded with high accuracy and tight sealing.

- More efficient energy transfer: The laser focuses energy directly and specifically on the welding points, reducing energy consumption. This minimizes heat absorption by the components and prevents distortions caused by internal stress release.

- New application opportunities: In a joint development (by bielomatik, LZH and Coherent), a CO2 laser was controlled to allow process-safe, flexible and gentle welding of IR-transparent components. For example, a taillight with a housing made of ABS/PC and a lens made of PMMA (Fig. 4).

Targeted energy transfer

The laser-based infrared welding process offers numerous advantages through its precise energy transfer and high precision:

- Prevention of thermal material damage: The precise focusing of the laser allows controlled and efficient energy delivery to the weld zone, significantly reducing energy consumption.

- Cost-effectiveness and environmental friendliness: The process enables exact control of energy input, tailored to material and geometry, resulting in optimal welding outcomes.

- Low thermal stress: Heat generation is confined exclusively to the weld zone. The rest of the component remains cool and intact, which is particularly advantageous for temperature-sensitive components.

- Shorter commissioning and parameter setting: The programmable IR emitter enables precise, reproducible and transferable parameterization of project data, saving significant time during commissioning and implementation in production processes. This makes it particularly suitable for series production.

Conclusion

The laser-based infrared welding process developed by bielomatik offers significant improvements in precision, efficiency, and material versatility. The process is cost-efficient, sustainable and highly flexible. This technology not only opens new application possibilities, such as in lighting manufacturing, but also provides a very economical alternative to

conventional infrared welding techniques. By combining the advantages of laser scanner systems with the economic and ecological benefits of infrared welding, this process is well-suited for a wide range of production applications, from automo-tive to medical technology.

(Source: Beatrice Maus, bielomatik)

Schlagworte

EnvironmentInfraredJoining PlasticsLaserPolymerWelding

![Joining Plastics [EN]](/images/frontend/journals/joining-plastics_sm.png)