Digital transformation for Increased efficiency

With the new C-Gate Operation Module, Cloos is advancing the digital transformation of welding production. The extension to the C-Gate digitization platform offers an optimized solution for programme and user management and ensures more efficiency and safety in production.

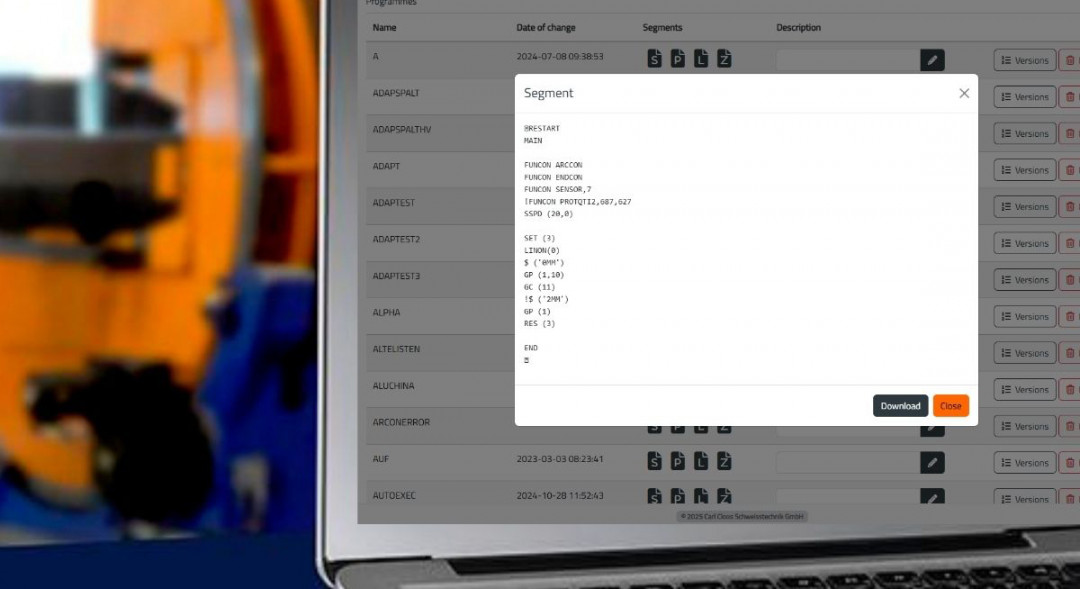

Programme management is a key component of the extension and enables precise management of programme versions. By saving programme versions, all modifications are documented and can be traced at any time. If restoring an older version is neccessary, it can be done with just a few clicks. Automated processes, such as loading and saving programmes, make handling easier. With the C-Gate Operation Module no data is lost, the latest programme is always available at every workstation and executable programmes are always used.

The module offers a flexible and secure solution for user administration. Freely configurable roles for software and hardware allow customized adaptations to the specific company's requirements. The assignment of rights is based on the skills of the individual employees. Logging in by using the PAK key creates an additional security factor to prevent unauthorised access and maintain the integrity of the system.

Another feature is the CarolaEdi network connection, which links the Cloos offline programming tools directly to the C-Gate platform. This future-proof technology makes it possible to access all relevant data from any workstation in the company.

(Source: Carl Cloos Schweisstechnik GmbH)

Schlagworte

DigitalizationManagementProcessingWelding