Performance Matters

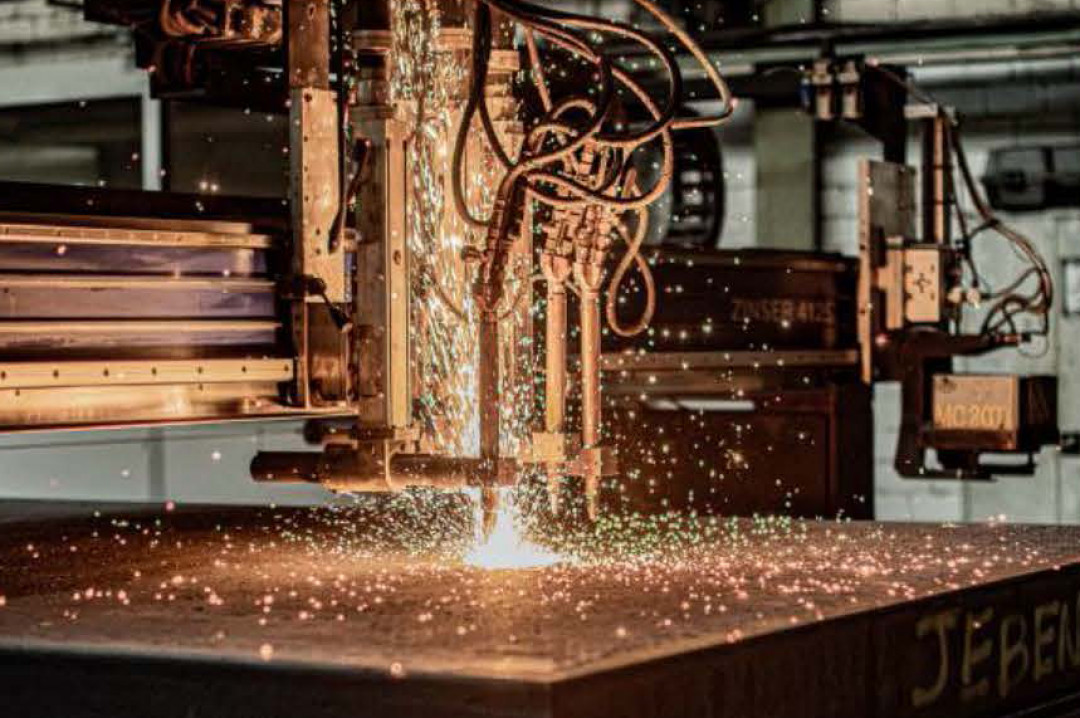

An international manufacturer of systems and products for plate and fiber forming appreciates the flexibility of Jebens GmbH, headquartered in Korntal-Münchingen. In addition to the production of large, heavy flame-cuts, the flame-cutting expertise is also welcome support in cases of production bottlenecks.

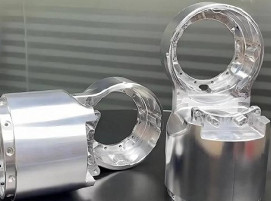

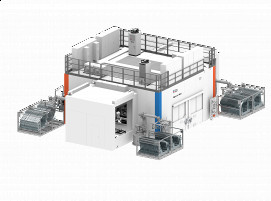

For more than 50 years, the Scandinavian company has specialized in complete solutions for sheet metal forming. One focus today is on systems for hot and cold forming a wide range of materials. The main customers are companies from the automotive, household appliance and energy industries.

The press manufacturer regularly commissions Jebens with the production of large-format flame-cut parts. The specialist for particularly large flame-cut parts, mechanical processing and complex welded assemblies produces cut parts with a total weight of several hundred tons for the company every year. The decisive factor for this constant cooperation between the two companies is Jebens' large plate warehouse, which is one of the largest in Europe for high-quality steels in thicknesses ranging from 100 to 650 millimetres. No less important for the plant manufacturer, however, is the equally precise and on-time production of blasted and chamfered flame-cut parts, such as tool plates. In addition to large and heavy flame-cut parts, Jebens also usually supplies complete kits with all of the steel parts required to build a press – from very small to extremely large parts.

(Source: Jebens Press ReleaseI)