Robotics is getting smarter and smarter. Better perception, smarter control loops and higher autonomy only translate into real performance when the hardware can deliver predictable motion. For custom robotic projects, that is typically won or lost in the details: datum strategy, tolerance stack-up, bearing fits, coaxiality and the quality of interfaces around high-DOF joints. CNC precision machining remains one of the most direct ways to help to turn a concept into a repeatable, production-ready system – especially when joint mechanisms must be compact, stiff and low-backlash while carrying sensors and routing cables.

Robotics Is getting smarter

As robot platforms evolve, they are moving toward denser integration and higher functional complexity used in various industries, like medical, home services. More axes, more sensing and tighter packaging all raise the bar for precision robot parts. In some countries with advanced robotics technology humanoid robots have taken to the stage to perform group dances. In practice, the components that “just hold things” often become the components that define coordinate frames, control stiffness and long-term accuracy. This is where CNC machining matters: it creates stable reference geometry for joint mechanisms, axes alignment, actuator interfaces and vision sensor mounting – without sacrificing iteration speed.

Kinematic structure

DOF (Degree of Freedom) is not just a specification, it is a multiplier for error. Each additional axis introduces another set of interfaces – bearing seats, housing bores, mounting planes and locating features. If those references are not controlled, small deviations compound along the kinematic chain and show up at the end-effector as missed positions, unstable trajectories or increased tuning effort. Robotic machining supports robust kinematic structure by holding true datums – coaxial bores, square faces and repeatable locating features – so the robot’s geometry remains consistent from prototype to production.

High-precision servo motors

High-resolution servo motors and encoders can deliver impressive control, but they cannot “average out” mechanical misalignment. When motor mounts lack flatness, pilot diameters are off or couplers introduce eccentricity, the system pays the price in runout, uneven bearing load, heat and noise. Over time, that becomes wear and drift. CNC precision machining helps servo performance stay honest by producing accurate mounting interfaces, controlled concentricity and stable fits at the motor–gearbox–shaft stack.

Actuation and end-effectors

Actuators and end-effectors are where torque and force become application results. Whether the architecture uses harmonic drives, cycloidal reducers, belt stages or custom linkages, the quality of torque transmission depends on interface geometry. CNC-machined brackets, adapter plates and tool interfaces help preserve stiffness and alignment under load and they reduce the “mystery compliance” that complicates control tuning. For end-effectors, consistent tool-center-point behavior often comes down to repeatable mounting patterns, controlled locating surfaces and predictable assembly fits – exactly the strengths of CNC machining.

Sensing

Vision sensors do not exist in isolation; they live inside mechanical frames that define their orientation and stability. Small angular errors in a sensor bracket or drift in a mounting plane can shift calibration and degrade perception accuracy, particularly when the robot must reconcile camera coordinates with joint coordinates. CNC machining enables stable sensor integration through accurate reference faces, robust housings and tight positional control, helping vision sensors maintain alignment through vibration, thermal cycling and routine service events.

Why CNC machining matters

In robotics manufacturing, “good enough” geometry is rarely good enough for long. Performance in the lab can hide fit issues that become expensive in deployment: backlash growth, joint heating, bearing wear, calibration drift and inconsistent assembly outcomes between units. Many robotics companies choose a hybrid manufacturing model combining additive and subtractive manufacturing for processing parts with higher requirements. In this process, CNC machining, especially custom CNC machining, is crucial during both prototype testing and mass production.

Demands on precision

Robotic joints are sensitive to geometry because they concentrate load paths and define motion. Backlash, friction and wear are often symptoms of interface errors – improper fits, misaligned bores or inconsistent bearing seats. This is why robotics drawings commonly call for controlled tolerances and GD&T on functional features: true position for fastener patterns, coaxiality for rotating interfaces, perpendicularity for mounting planes and stable datums for assembly. CNC machining (on-demand manufacturing) is valued here because it can hold assembly-driven requirements – often including targets such as ±0.01 mm on critical interfaces – so parts seat correctly and joints behave consistently.

High accuracy and repeatability

Accuracy ensures a single part matches design intent. Repeatability ensures the next 100 parts match it too. In robotics, repeatability is what protects calibration workflows, assembly takt time and field reliability. Consistent parts reduce rework, reduce “hand fitting” and help teams differentiate control issues from mechanical variability. For procurement and manufacturing stakeholders, repeatability improves supplier confidence and supports scalable production planning.

Fast iteration for custom needs

Custom robotic projects rarely stabilize on the first revision. Packaging, cable routing, stiffness targets and mounting standards evolve as teams learn from test data. CNC machining supports this reality because design changes can flow from CAD/CAM to physical parts without tooling-heavy delays. That keeps iteration cycles short while still maintaining dimensional control on the interfaces that matter most.

CNC for high-DOF robot joints

High-DOF joints are where CNC capability directly translates into motion quality. These joints pack motors, reducers, bearings, sensors and structural elements into compact assemblies with limited tolerance for stack-up. When the mechanical stack is right, the robot feels “tight”: low backlash, smooth motion, stable force response, and predictable thermal behavior. Multi-axis CNC machining, like 5-axis machining, enables that outcome by controlling the geometry that defines alignment and load distribution.

Less backlash and better fit

Backlash is not just a gear problem, it is an interface problem. Loose fits, inconsistent seating and misalignment can introduce micro-play when the gearbox is high quality. CNC machining supports controlled fits between shafts, couplers and gearbox interfaces, helping joints maintain tight engagement and consistent behavior across repeated cycles and load reversals.

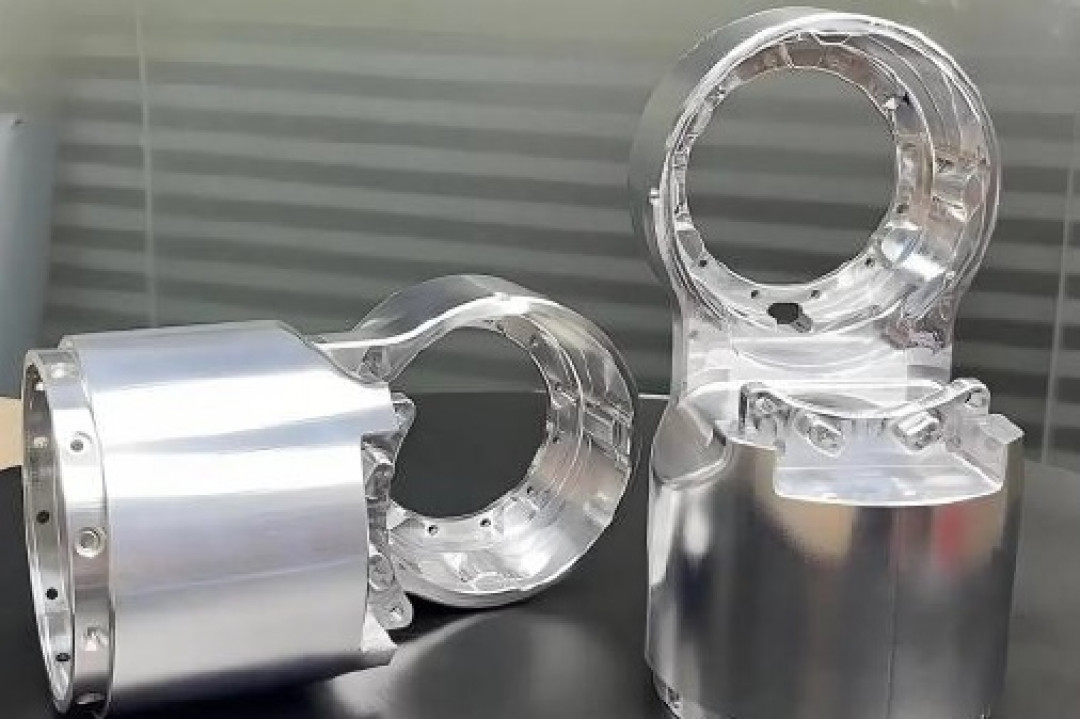

Complex joint geometry

High-DOF joints often require multi-angle faces, deep pockets, sensor passages and weight-optimized structures – while still maintaining stiffness and alignment. Multi-axis CNC machining produces these geometries with fewer setups, which reduces accumulated error and improves the relationship between functional surfaces, compared to basic machining. That setup reduction often matters as much as the raw tolerance number.Tuofa CNC Machining recently helped a robotics company customer complete a difficult project, from 10+ other designs.

Typical CNC robot parts

Many CNC robot parts are “reference parts”: they locate subsystems and define the assembly’s truth. The best control algorithm cannot compensate for shifting datums, variable fits or inconsistent alignment features. CNC machining is widely used across robot platforms because it produces these reference-defining components with repeatable geometry that supports precision assembly and reliable integration.

Joint housings and brackets

These components carry loads and define alignment for motors, reducers, bearings and sensors. Accurate bores, consistent mounting faces and well-controlled locating features reduce assembly variability and help joints remain stable as load and temperature change.

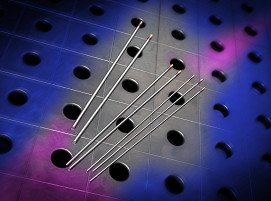

Shafts, couplers and mounts

Rotating components are sensitive to runout and concentricity. CNC machining supports stable drivetrain behavior by controlling critical diameters, fits and surface finishes – reducing vibration, improving torque transfer and protecting bearing life.

End-effector adapters

At the wrist, small errors become visible at the process. Precision-machined adapters and interfaces help maintain a stable tool center point, supporting consistent application results in assembly, inspection, handling or specialized tasks.

Design for precision assembly

In robotics, tolerances are often specified to protect assembly behavior, not aesthetics. A joint shaft, bearing fit or locating boss may require ±0.01 mm to minimize play, preserve preload and keep alignment stable over time – improving interchangeability and reducing commissioning effort.

Common robotics materials

Material selection in robotics is a balance between stiffness, weight, wear behavior and environment. CNC machining supports that balance because it can produce accurate, repeatable geometry across metals and engineering plastics – while preserving the integrity of tolerance-critical features. For robotics manufacturers, the material decision is most successful when it is tied to the load path and to the interfaces that define alignment.

Metals used in robotics

Metal parts (commonly aluminium alloys, stainless steels and titanium alloys) are used where stiffness, stability and durable interfaces matter. Plastic parts are used for covers, insulators, cable guides and functional components where weight reduction or electrical isolation is important. CNC machining supports both categories, particularly at mating interfaces where dimensional control governs assembly quality.

How to choose the right materials

Choosing the right materials by start with functional requirements: stiffness for precision mounts, wear resistance for moving interfaces, corrosion and temperature constraints for the environment and weight limits for moving links and end-effectors. Material choice should also reflect manufacturability – especially on tight fits, thin walls and tolerance-critical geometry.

How CNC bustom machining improve robots business?

Robotics is a time-and-risk business. Teams need fast learning cycles in prototype robot and they need stability when scaling to production. CNC custom machining contributes to both: it improves prototype fidelity, shortens development loops by reducing mechanical unknowns and supports stable mass production through repeatable quality and measurable inspection.

Robots prototyping

Test prototypes, such as those from Tuofa CNC Machining, help clients select a design from 10+ options and refine challenging designs. As one of the companies making custom vehicles, machinery and robotics, Tuofa CNC Machining helps customers machine parts to a precision of ±0.01mm and also provides testing and assembly services to meet their customized needs.

More stable mass production

Stable production depends on repeatable parts, clear inspection criteria, and predictable assembly behavior. CNC machining supports consistent batches and reliable fit, improving yield and supporting field reliability as robotics platforms scale.

Conclusion

Smarter robots demand tighter mechanical truth. As DOF increases and integration becomes denser, joint quality, alignment stability and precision assembly become decisive performance factors. CNC precision machining provides the accuracy, repeatability, and iteration speed that custom robotic projects need – particularly in high-DOF joint mechanisms where fit, seating and reference geometry define real-world motion outcomes.

(Source: Tuofa CNC Machining)

Schlagworte

AluminiumAutomationCAM/CADCNCMetalMillingRoboticsRobotsSheet MetalSteel