Replique, a production platform for industrial components, is expanding its collaboration with Alstom worldwide. What began with initial projects, such as door stoppers and tank caps, has grown into a long-term partnership. Replique now serves as a global supplier for numerous projects and subsidiaries, including locations in Singapore, Brazil, Australia, France, Italy, Germany, Thailand and Spain.

One partner for all manufacturing technologies

With Replique, Alstom benefits from having a single partner for a wide range of manufacturing technologies. Whether 3D printing, CNC machining, casting, forging or other processes, Replique evaluates each component to determine the most cost-effective and technically optimal solution. When needed, Replique manages the entire process – from design and qualification to production, finishing, quality assurance and delivery to the end customer.

Replique has already produced volumes in the lower five-digit range for Alstom. These parts – made from materials ranging from stainless steel to flame-retardant plastics – are in daily use across railway operations, with all of them meeting Alstom’s specific testing and qualification requirements.

“We are proud to provide Alstom with global solutions that make their parts supply more efficient and flexible. Our components are used in series production, and each project highlights the diverse challenges of parts procurement while motivating us in our vision of a globally connected, sustainable, and efficient supply chain,” says Dr. Max Siebert, CEO and Co-Founder of Replique.

Practical examples of the collaboration

The versatility of this partnership is evident: an impeller in a metro solution cooling unit in Asia needed replacement. While the original manufacturer only offered to replace the entire block, Replique produced the single component and handled every step of the process – from metal 3D printing and balancing to precision milling and final corrosion-resistant coating. This sustainable solution allowed the locomotive to be returned to service quickly.

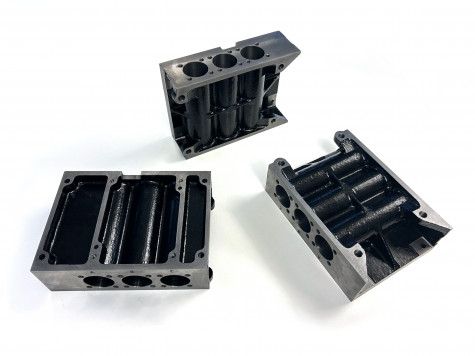

In Italy, Replique quickly delivered cast intercoolers to restore a train from the 1960s. Since the previous supplier was no longer available, Replique ensured production using 3D-printed casting molds, securing long-term spare part availability.

(Source: Replique GmbH)

Schlagworte

3DAddtiive ManufacturingCastingCNCManufacturingPartnershipPlasticsRailwaySteel