Robotic Hand Learns to Feel

Making harvesting robots, submarine grippers and autonomous rovers on distant planets more universally applicable and autonomous in the future – researchers at the Fraunhofer Institute for Material and Beam Technology IWS in Dresden work on enabling them to “feel”: In various projects, they are working with academic and industrial partners on biomimetic artificial grippers. Combining 3D and dispensing printing with other technologies shall achieve this – fish also have a major influence.

The concept: flexible, 3D-printed grippers use sensors to recognize how firmly they may grip without causing damage. Technical systems such as robots or other machines shall learn to grip “delicately”, similarly to a human hand. Future applications include harvesting robots that pick strawberries without bruising them or autonomous rovers that safely retrieve unknown samples. In publicly funded projects such as “BioGrip” or “Nature4Nature”, nature inspires researchers to solve problems. They try to understand the underlying biological principle, imitate it technologically, and develop it further. This approach is often referred to as bionics or biologization.

“Technological advances in additive manufacturing now allow us to adapt many more biological concepts than before,” emphasizes mechatronics engineer Hannes Lauer from Fraunhofer IWS, who oversees the BioGrip project. “Nature is full of solutions. If we as engineers are not making any progress, it is always worth looking at nature's concepts.” Moritz Greifzu, Group Manager Process Chains and Product Design, adds: “Bio innovation processes often take several years and currently still require a lot of support and, above all, interdisciplinary collaboration. The aim is to train a new generation of engineers with a strong network and experience of complete bionic innovation processes.”

“Finray” Effect: Fin Grabs Object

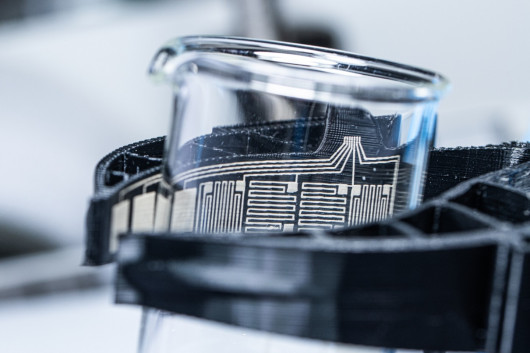

In this specific case, the project partners utilize the ability of certain fish’s fins to react to pressure with a counter-movement rather than an evasive one, meaning that they enclose the opposing force. The fish themselves use this to move more easily. The engineers used this finray effect as part of the BioGrip project conducted between mid-2021 and early 2023. Thanks to the finray structure, they have printed grippers equipped with sensors that can gently grab objects, a dispensing printer then applies fine structures made of silver paste to the surface of the gripper. Infrared radiation functionalizes the generated patterns. These functional structures include, for example, a meander pattern of 250-micrometer narrow conductor paths. If the individual finger bends or stretches, the electrical resistance of the meander changes. This enables real-time determination of the gripper's tension at any time.

The printer also generates thin layers of silver and insulators on top of each other on the gripper fingers, creating a flat capacitor. If an external force presses the two silver layers together, the capacitance of the capacitor changes. This allows the force acting on the gripper to be determined. The dispensing printer can also produce touch-sensitive and other surface sensors. Combined with microsystems in the integrated control and evaluation electronics, this can simulate various other human hand functions. It would be conceivable, for example, to estimate the weight of the object being gripped by gently shaking it.

Bionic Grippers for Mars and Seabed

This combination of several additive printing processes and other technologies creates autonomous grippers that can “feel” what they are gripping. Interest in industry and research is already growing. One topic under discussion is the collection of samples with unpredictable shapes on Mars. Food companies could use such retrofitted robots to sort and pack apples or other fruit gently. Biologists could use “tactile grippers” to collect small sea urchins, sea cucumbers and other ocean dwellers without injuring them. Further application scenarios are likely to follow.

BioGrip is just one of several projects at Fraunhofer IWS in which nature serves as a blueprint or source of inspiration. These include laser systems that engrave lotus effects and other natural tricks to repel dirt, ice or friction as fine patterns on surfaces. In the Nature4Nature project, the Dresden bionics experts are working with partners from industry and research on new types of filters to prevent sewage treatment plants from flushing microplastics into natural water cycles and ultimately into the world's oceans. Here, the researchers have been guided by the ability of some Rays, paddlefish, and other ocean suspension feeders. These sieve their favorite foods, such as plankton and other microorganisms, out of the seawater using unique structures that have evolved over time. How this works exactly is still the subject of research. However, biologists already understand many of the principles. For example, the paddlefish have naturally grown arches and rakes in their gills. Together, they form stepped structures. Vortices form where the desired food particles collect in the spaces between them. In the mouths of the manta rays, the particles bounce off small structures and reach the pharynx with the main current, while the water can penetrate to the outside.

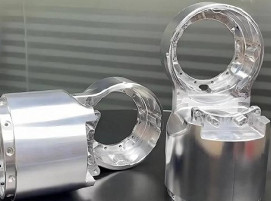

The project partners want to transfer these and similar capabilities to self-cleaning filters that sieve microplastic particles from wastewater. Special 3D printers will create the bionic structures. Rapid prototyping is already widely used in bionics, but there is still a lack of accepted materials and processes in additive manufacturing that meet industrial standards. This and the transfer of such technologies to industry are part of the Fraunhofer IWS expertise. Regardless, its researchers remain convinced that the combination of biology and technology holds significant potential: “The combination of several additive processes opens up completely new possibilities in bionics,” predicts Hannes Lauer.

(Source: Fraunhofer IWS Press Release)