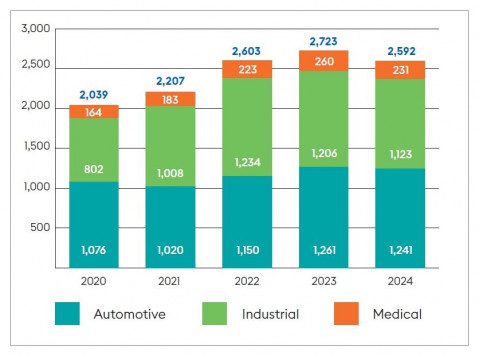

The Röchling Group was not entirely immune to the challenging market conditions in fiscal year 2024: The internationally active plastics processor, headquartered in Mannheim, Germany, generated sales of 2,592 million euros, a decrease of 4.8 % compared to the previous year, primarily due to material price effects.

“Our divisions developed differently last year due to varying market conditions. In difficult times, we are only partially satisfied with the overall business performance. However, our strategy of diversification and the decentralized organization of our activities strengthen the business and provide support. This confirms the course we have taken, even though there are still tasks ahead of us,” says Raphael Wolfram, Spokesman of the Executive Board of the Röchling Group and, as of July 1, additionally CEO of Röchling Industrial.

The strongest-performing division in terms of revenue in 2024 was once again Röchling Automotive, which nearly matched the previous year’s level with 1,241 million euros (down 1.6 %). The division consistently continued its turnaround toward greater profitability and further expanded its product portfolio for sustainable mobility. In this context, the consolidation of sites in Germany progressed well and a high level of incoming orders was recorded once again. The Industrial division generated 1,123 million euros (down 6.%), with the decline mainly attributable to pricing effects. Overall, the division delivered a strong performance and repeatedly demonstrated its profitability. This helped offset the difficult market situation faced by Röchling Medical.

Due to the continued reduction of inventories in he medical technology and pharmaceutical industries following the pandemic, the smallest division faced significant strain alongside internal challenges. As a result, after several consecutive years of growth, revenue declined to 231 million euros last year (down 11.1 %).

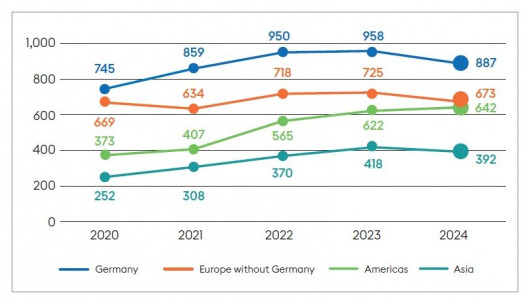

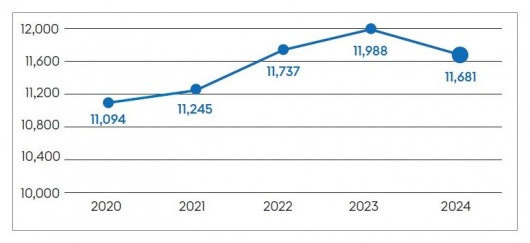

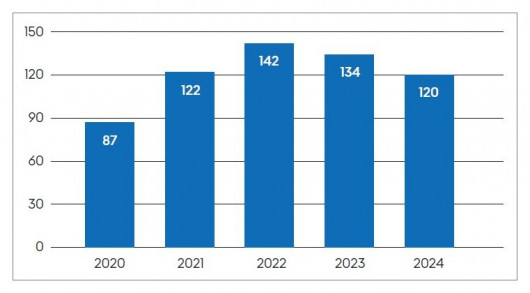

In Germany, Röchling Group’s revenue fell to 887 million euros (down 7.8 %), and in the rest of Europe to 673 million euros (down 7.2 %). Business in Asia declined to 392 million euros (down 6.2 %. In contrast, the Americas proved to be a growth region, with volume increasing to 642 million euros (up 3.2 %). The number of employees also declined, falling by 307 year-over-year to 11,681. This was mainly due to the consolidation of German sites within Röchling Automotive. A total of 289 trainees began their careers at the Röchling Group (previous year: 307).

The challenging market environment persisted into the first quarter of 2025. In the first three months, the Röchling Group generated sales of 662 million euros, 34 million euros less than in the same quarter of the previous year. However, the number of employees rose slightly to 11,729. Despite unclear U.S. trade policies, ongoing geopolitical tensions and persistently high energy and raw material prices, the Group expects stable revenue for the current fiscal year.

“Despite all the challenges in global markets, technical plastics continue to play an important role and the industry will continue to grow. We believe we are still well positioned for the future and are solidly financed,” says Evelyn Thome, CFO of the Röchling Group.

Röchling automotive: transformation strategy takes effect

In fiscal year 2024, the Röchling Automotive division demonstrated stable revenue performance – despite consolidation measures and a persistently challenging market environment. With revenue of 1,241 million euros, the division fell only slightly short of the previous year’s level. Investments in property, plant and equipment totaled around 34 million euros, underscoring the focus on cautious cash management. At year-end, the number of employees stood at 5,733 (previous year: 6,082). 85 apprentices were undergoing vocational training at Röchling Automotive.

The automotive supply industry continued to face profound challenges in 2024. The slow transition to electromobility, strategic realignments by customers and increasing competitive pressure from China shaped the international market environment. As a result, Röchling Automotive implemented further restructuring and consolidation of its production sites in Germany, closing the Wackersdorf plant and the site of its subsidiary Röchling Precision Components in Mainburg.

“We have consistently pursued our strategic direction and held our ground in a changing market,” says Martin Schüler, CEO of Röchling Automotive since February 1, 2025. The focus was on strengthening in-house development capabilities, closer collaboration with customers, and better utilization of global capacities. The commitment to sustainable mobility solutions remains a central part of the strategy.

First Quarter 2025 and Outlook

In the first quarter of 2025, Röchling Automotive generated revenue of 303 million euros. The market environment remains complex: ongoing uncertainty in international trade and the effects of global trade policies have led to restrained investment activity among manufacturers and suppliers. As part of optimizing its global production network, Röchling Automotive announced in April that it would close its plant in Chengdu, China, by the end of the year and shift production to other Chinese locations. Numerous factors influenced the decision, including optimal utilization of existing capacities and investments, customer structure and supply chain considerations, and political conditions. “Our goal remains to further enhance our competitiveness, maintain our targeted profit margin, and intensify our acquisition efforts to position ourselves optimally in this dynamic market environment and return to global growth,” says Schüler.

Röchling industrial: composites as growth drivers

Röchling Industrial closed the 2024 fiscal year with a very strong result, despite lower selling prices due to material cost effects and weak performance in sectors such as the chemical industry and mechanical engineering. With revenue of 1,123 million euros, the division came in just slightly below its own expectations. At the end of last year, Röchling Industrial employed 4,623 people (an increase of 108), including more than 160 apprentices. The market for thermoplastic semi-finished products remained challenging in 2024. A weak market environment – combined with intense competition – led to a significant drop in prices. “We successfully countered these challenges with active cost management and a very strong order situation in the composites product line,” says Franz Lübbers, CEO of Röchling Industrial. The composites segment continues to benefit from megatrends such as the energy transition and the expansion of public transportation, and serves as a strategic cornerstone and key growth market.

In 2024, Röchling Industrial invested more than 74 million euros in property, plant and equipment, including the construction of a new Engineering Center in Lahnstein/Germany, as well as modernization and expansion projects in Nancy/France. The company also established a new site in Chuzhou/China, to further expand and strengthen its leading market position for high-performance plastics in the growth region of Asia. Röchling Industrial is also consistently pursuing its sustainability strategy and expanding the Röchling Sustainability Center in Geeste-Dalum/Germany. “With this investment, we are strengthening the circular economy and expanding our international leadership role over the long term,” emphasizes Lübbers.

At the beginning of the year, there was no relief in the market for thermoplastic semi-finished and finished parts. Despite continued pressure in the markets, Röchling Industrial maintained its successful trajectory at the start of the year. While demand for thermoplastic semi-finished products remains low, there is currently strong demand for composite products, particularly in the transportation and energy industries.

The outlook for the future is positive, Lübbers emphasizes: “We expect Röchling Industrial to continue its successful business development throughout the year. Our focus is on strengthening our market leadership, further expanding the composites business, and advancing internationalization and the circular economy.”

(Source: Röchling Group)

Schlagworte

AutomotiveEnvironmentIndustryJoining PlasticsKPlasticsProcessing