project to analyze hydrogen leakage

The German government's new import strategy is intended to provide Germany and its economy with a sufficient supply of hydrogen and H2 derivatives. Hydrogen is an increasingly relevant topic and a growing number of components, including pipelines, must be capable of withstanding its use. Hahn-Schickard, Villingen-Schwenningen, Germany and the SKZ Plastics Center, Würzburg, Germany have joined forces to address this topic.

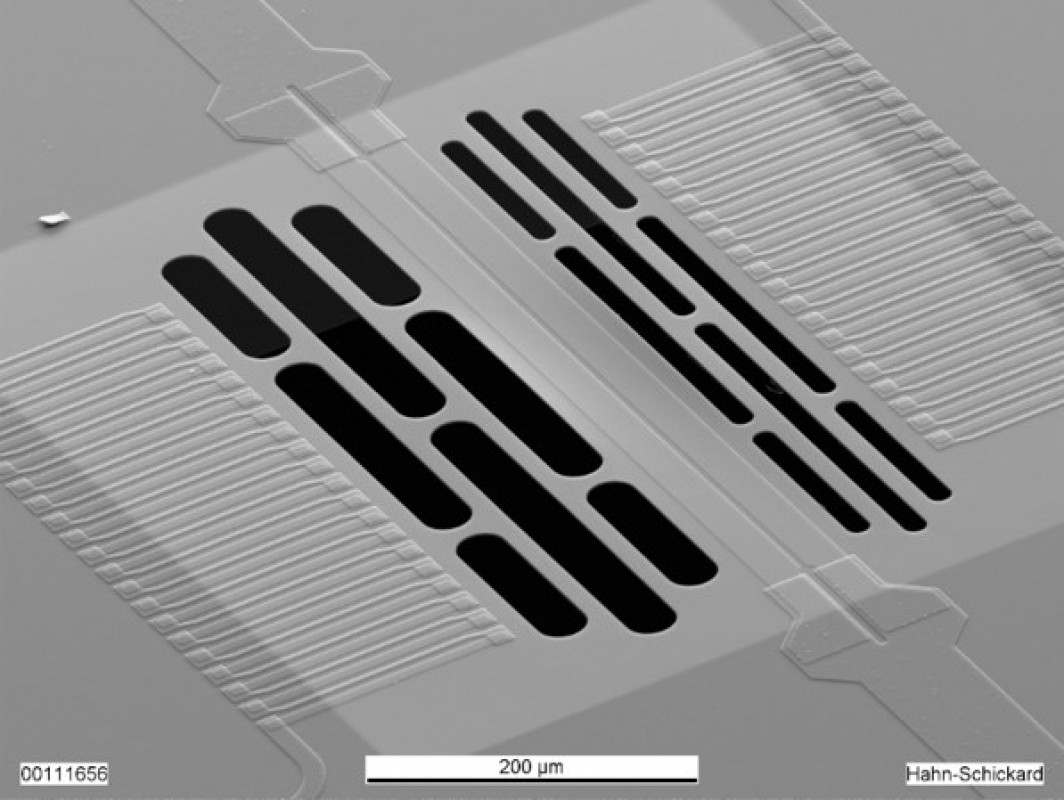

Hahn-Schickard manufactures solutions using microsystems technology, so-called microelectromechanical systems (MEMS). These systems are smaller than a fingernail and are also used in the field of hydrogen-guided parts. As Europe's largest institute in the field of plastics, the SKZ would like to integrate such systems into pipes and plastic components, for example, in order to establish a warning system for H2 leaks. In the scope of the H2Sens project, the two institutes are working together to develop and validate a cost-effective hydrogen (H2)-selective sensor concept for H2-bearing components and semi-finished products. The prototypes created as part of the project will be tested for their sensitivity in a specially developed measuring chamber. The H2-selective sensors will then be attached to weak points of hydrogen-bearing components (such as sleeves or weld seams) to enable rapid intervention in the event of a hydrogen breakthrough.

“In the field of flow sensors, customer-specific silicon sensors and sensor modules have been developed for various applications in the past. The MEMS clean room is ISO-certified (ISO 9001:2015) and offers individual process steps through to complex production runs,” says the project manager at Hahn-Schickard.

Hahn-Schickard (HS) uses a process technology for the selective ablation of sacrificial layers to produce surface micromechanics (OMM) structures with precise gap dimensions down to a few hundred nanometers. This enables a new generation of miniaturized thermal sensor structures with specific sensitivity due to the drastic aspect ratios. With this technology, highly integrated pressure, temperature and thermal gas sensors can be produced on a single sensor chip, which allow very precise compensation for thermal gas analysis due to their location at the same measuring point. The areas of application for the sensor technology extend along the entire value chain of H2 applications – from efficiency monitoring in electrolysis or fuel cells to accelerated material development and safety monitoring of transportation and storage infrastructure (pipes, tanks).

The SKZ is climate protection company and a member of the Zuse Association. This is an association of independent, industry-related research institutions that pursue the goal of improving the performance and competitiveness of industry, especially SMEs, through innovation and networking.

(Source: FSKZ e. V.)