You will find the company at the fair in Hall 1, Stand 1D12.

You will find the company at the fair in Hall 1, Stand 1D12.

![SCHWEISSEN & SCHNEIDEN 2025 [EN]](/images/frontend/journals/dvs-sus_sm.png)

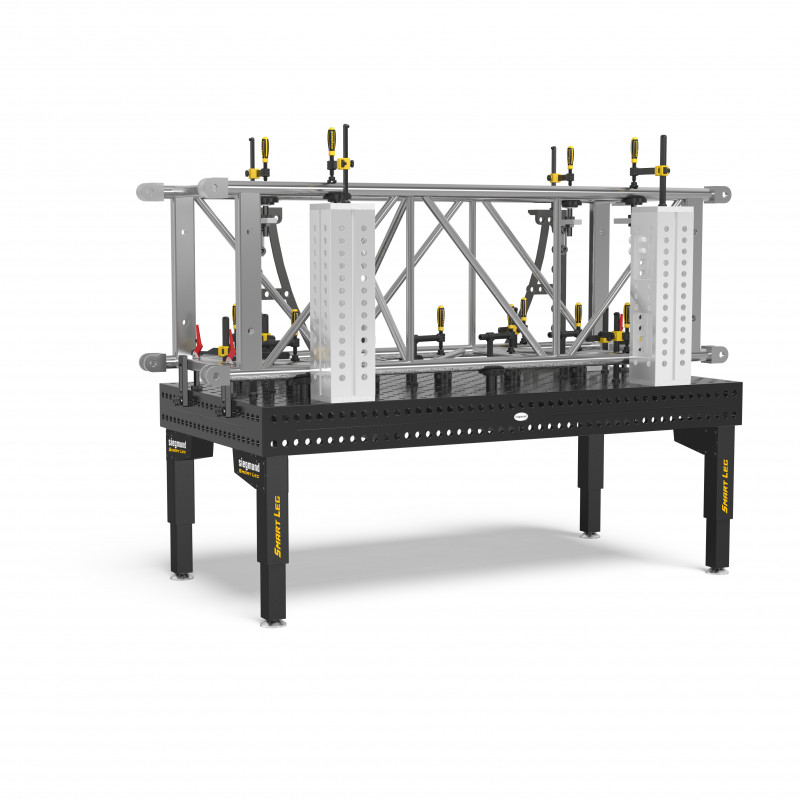

Siegmund is presenting the Smart Leg, an electrically and continuously height-adjustable table leg, for the first time. It combines state-of-the-art electronics, load-bearing capacity and intelligent control – developed to improve work in the metalworking industry. Designed to be innovative, powerful and versatile, it emphasizes ergonomics and efficiency.

Strength meets flexibility

With its load-bearing capacity and flexible height adjustment, the Smart Leg marks the beginning of a new era in ergonomic welding workstations. Its robust construction ensures stability even under high loads. Thanks to its universal design, the Smart Leg can be seamlessly integrated into new workstations as well as retrofitted to existing welding tables. This allows users to benefit from this world-first innovation at any time, regardless of their current table configuration.

Technical highlights at a glance

- Electric, stepless height adjustment

- 300 mm stroke

- Load capacity: 4 tons per leg

- Swivel base plates for maximum stability

- Control unit with display and emergency stop

- Ready for immediate use – optionally with 18V battery system or mains operation

- Suitable for tables with 4, 6 or 8 legs

- Compatible with Siegmund System 16, 22 and 28

- Can be retrofitted to all welding tables

Intelligent control

The Smart Leg control system offers flexibility and can be individually controlled, allowing the table height to be accurately adjusted to the workpiece and the work process. Also complex inclinations can be adjusted automatically – an advantage for ergonomic work in variable positions. The integrated auto-leveling system guarantees precise horizontal alignment of the table surface, regardless of load distribution or surface. For large-format applications, multiple tables can be linked in master-slave mode and controlled synchronously.

- Individual control of each leg for targeted adjustments

- Automatic tilt up to 8 degrees

- Auto-Leveling: automatic leveling of the table top

- Master-slave operation: multiple tables can be controlled synchronously

Programmable functions

With its programmable features, the Smart Leg brings welding table technology into the connected future. Individual user profiles can be accessed at the touch of a button via RFID, while the memory function stores recurring working heights and reliably makes them available at any time. Furthermore, the open interface enables direct integration into modern production systems – whether digitally or analogue controlled. This transforms the welding table into more than just a tool, but an active component of automated production processes.

- RFID for retrieving individual height settings

- Memory function for up to four stored positions

- Interface for integration into production systems (digital/analog signals)

Experience live

Visitors to SCHWEISSEN & SCHNEIDEN 2025 will have the opportunity to see this live for the first time at Siemund's fair booth.

(Source: Bernd Siegmund GmbH)

Schlagworte

Intelligent ControlPPESCHWEISSEN & SCHNEIDENWeldingWelding TableWorkplace