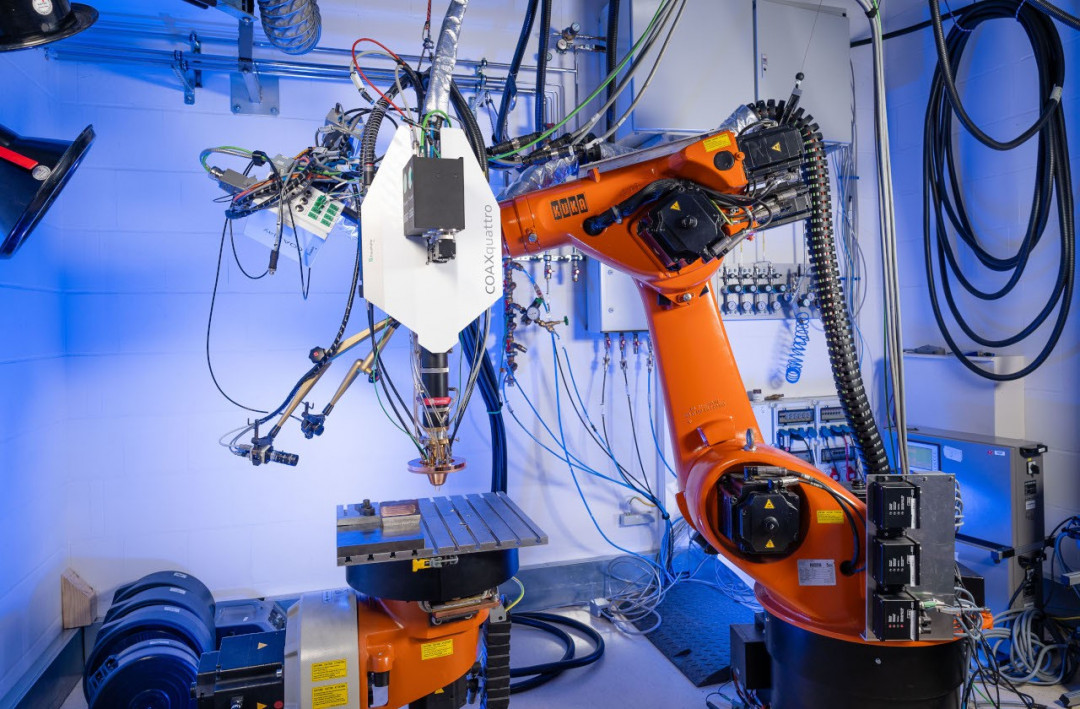

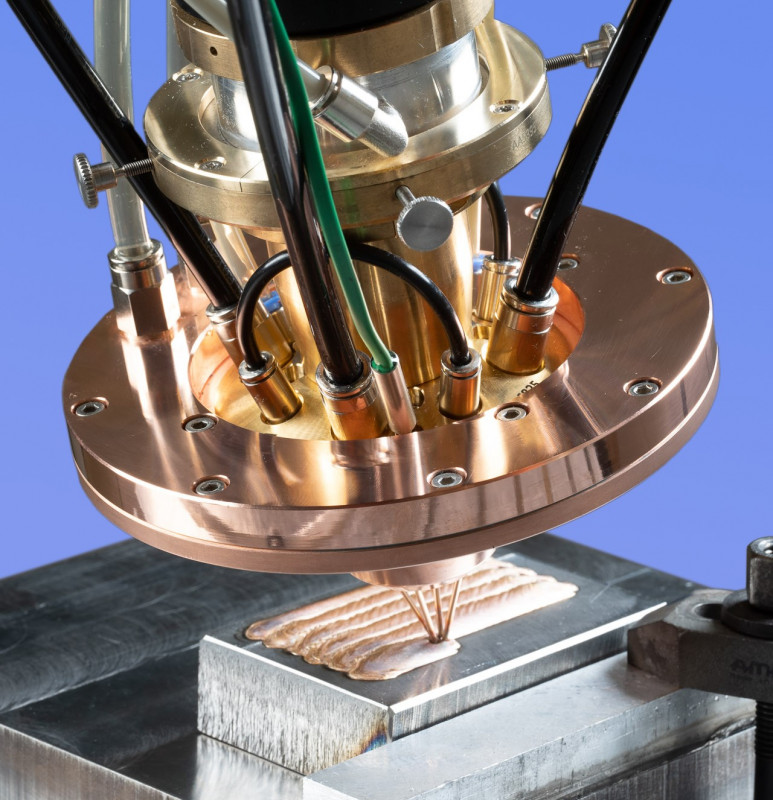

A new nozzle opens up perspectives for wire-based laser cladding in automotive and many other industries: The COAXquattro system by Fraunhofer IWS simultaneously feeds four wires into the center of the laser beam, increasing the deposition rate and energy efficiency of laser wire cladding for coatings, repairs or additive manufacturing. Systems equipped in this way achieve productivity rates previously reserved only for powder-based laser cladding. At the same time, the COAXquattro system reduces material costs, increases safety at work and improves the environmental balance.

As diode laser prices are falling, more and more companies are turning to laser cladding to coat or additively manufacture complex components. In this process, the system melts a metal-based powder or wire and manufactures the desired component from the molten metal layer by layer. Wire has been used primarily for small-batch repairs.

For larger production runs, on the other hand, users have previously preferred powder because it has allowed higher material deposition rates (for example, around 18 kilograms per hour for Inconel 625 using a 20 kW diode laser). However, powders involve increased occupational safety risks: Some of them are hazardous to health, others even explosive.

By automatically feeding four wires into the Fraunhofer IWS nozzle all at once, these laser cladding systems now also achieve cladding rates of around 18 kg per hour. However, while powder-based systems actually use a maximum of about 90 to 95 % of the feedstock material, the new nozzle head deposits effectively up to 100 % of the fed wire. In addition, wire costs approximately 50 % less compared to powder made from the same material, thus positively impacting manufacturing costs.

(Source: Fraunhofer IWS)

Schlagworte

Additive ManufacturingCladdingDEDLaserMetall AMPowder Bed Laser CladdingWire