Lessmüller Lasertechnik, a manufacturer of quality monitoring systems for industrial welding processes, is expanding its range of solutions to include automated weld seam inspection for gas metal arc welding (GMAW). The OCT 250 stand-alone sensor system uses optical coherence tomography (OCT) as a measurement method for continuous seam tracking and weld seam inspection in real time for automated GMAW processes.

The advantages for users are: OCT methods are more precise than conventional camera technology, the effort required for subsequent quality control is reduced and the user-friendly software also enables the evaluation and documentation of analysis data. Productivity increases and scrap can be measurably reduced.

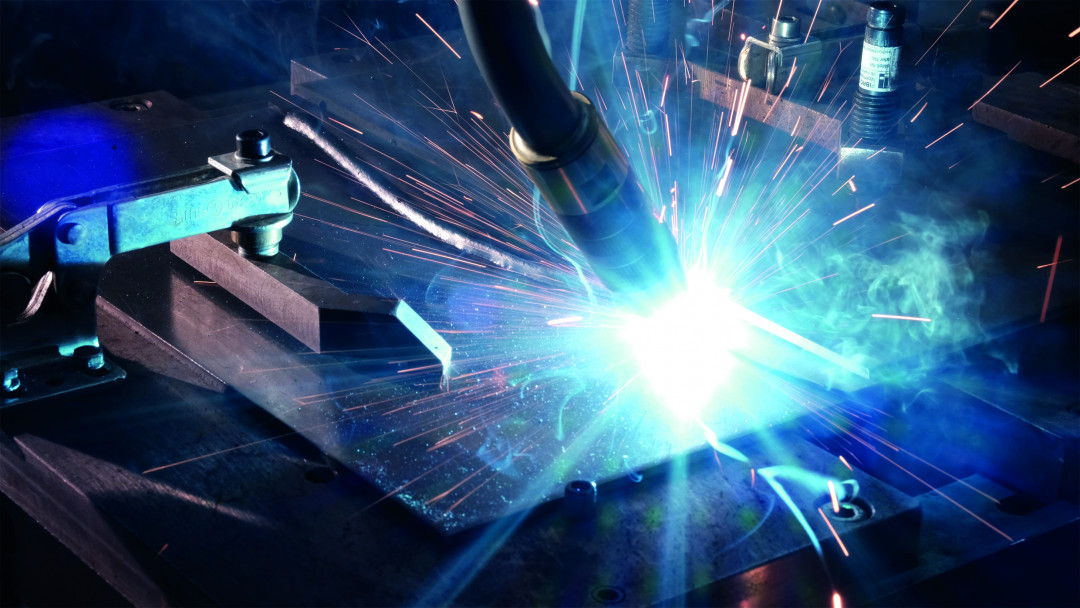

Arc welding, or GMAW, is widely used in the metalworking industry, in container and tank construction, in mechanical engineering, in rail vehicle and shipbuilding, but also in the furniture industry and other sectors. The process enables the joining of thin sheets as well as components with material thicknesses of up to 60 mm and is often used fully automatically and robot-guided in industrial environments.

In order to improve the productivity of automated GMAW welding and to reduce scrap caused by insufficient fusion of the welded joint, the welding process must be precisely controlled. Due to the high demands of robot-guided arc welding, previous process monitoring systems – with laser triangulation and CMOS cameras – are often considered inadequate. Lessmüller Lasertechnik's OCT technology now enables efficient quality assurance in arc welding for the first time.

Greater accuracy, better tracking and time savings

Similar to laser beam welding, the OCT 250 stand-alone welding sensor technology also enables pre-process seam tracking and post-process seam inspection during the ongoing welding process in automated MSG welding. Unlike conventional process monitoring systems with camera technology, the OCT sensor is completely insensitive to direct or diffuse light and blinding. It works reliable and with precision despite the arc itself, ambient lighting and reflective welding spatter. This insensitivity allows the measuring lines to be placed much closer to the TCP (Tool Center Point), thereby reducing passive travel distances which represent non-productive time. The OCT scanner can be mounted directly on a robot-guided welding torch.

For process monitoring, the system projects two OCT scan lines near the TCP. The first, ahead of the wire, captures the geometry to be welded and, if necessary, measures the dimensions of the gap. The second scan line runs behind the torch nozzle (after the arc) and scans the weld bead. This captures and maps quantitative and qualitative data such as weld seam length, profile, width, area and groove of the weld bead, convexity and concavity of the seam surface, undercuts and other defects, as well as surface porosity and craters. The tailormade application software allows all data relating to seam guidance and inspection quality assurance to be conveniently visualized, evaluated and archived for tracking purposes.

Based on the preceding seam tracking, the client software can issue control commands via fieldbus to the machine or robot control system and correct the robot's program sequence. For example, displacements, the welding angle or a combination of both can be adjusted and individually tailored to the respective joint type, the gap and overlap size. The evaluation of the post-process seam inspection allows comparison with predefined tolerances and, if critical errors are detected, can mark the components as rejects and even abort the welding process. This eliminates the effort and necessity of additional downstream quality controls.

(Source: Lessmüller Lasertechnik GmbH)

Schlagworte

GMAWLaserLaser Beam WeldingMeasuringMechanical EngineeringMetalworkingMonitoringMSG WeldingOCTOptical Coherence TomographyRail Vehicle ConstructionVehicle ConstructionWeldingWelding Torch