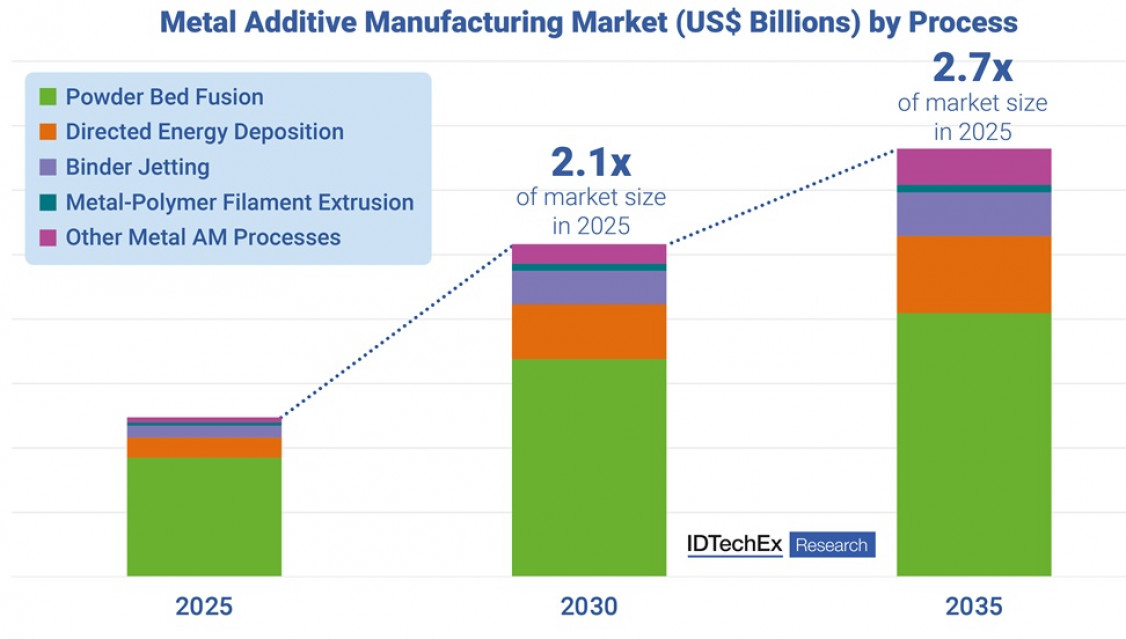

With the broader 3D printing industry, which encompasses material subspecialities like polymers, ceramics and electronics, metal additive manufacturing (AM) has particularly shown strength in recent years. As more users identify end-use applications for metal 3D-printed parts in sectors like aerospace, automotive, manufacturing, etc., it is clear that the industry is maturing beyond prototyping and tooling to penetrate high-value applications. This will help the metal AM hardware and materials market nearly triple its market size by 2035, according to IDTechEx's report Metal Additive Manufacturing 2025-2035: Technologies, Players, and Market Outlook.

Even in this highly differentiated billion-dollar industry, overflowing with many players and unique metal printing technologies, broader trends are still shaping the metal AM industry's direction, both in the short- and long-term. In this article, IDTechEx discusses the impact of three major trends; one technology-focused, one regional and one macroeconomic – on the status of metal additive manufacturing.

Powder bed fusion: Undisputed technology leader of metal AM

In the past several years, there has been significant hype around growing metal AM technologies, including metal binder jetting (MBJ) and metal-polymer filament extrusion (MPFE) (also known as bound metal extrusion). The unique capabilities of these technologies promised increased adoption by end-users who were otherwise not well-served by incumbent metal 3D printing technologies. However, the past several years has proven that laser powder bed fusion (LPBF), the first metal AM technology, has been and will remain the undisputed leader of metal AM technologies, according to IDTechEx forecasts.

Part of this stems from LPBF's maturity as a technology. As the first metal AM technology to be commercialized, it is backed up by years of manufacturer and end-user experience that enable it to be used effectively. In many cases, end-users of growing technologies, like MBJ and MPFE, are still working to address pain points in these processes and to identify applications where these processes, particularly MBJ, are technologically and economically advantageous.

Additionally, LPBF is a highly versatile technology. Depending on the configuration of the printer (i.e. build size, number of lasers, etc.), LPBF can be used for everything from small injection molds to massive rocket engines. In contrast, MPFE is best suited for prototyping, jigs, and fixtures, while MBJ is best for high volumes of small to medium-sized parts that have geometries compatible with the sintering process. The versatility of LPBF ensures that the technology will continue to lead the metal AM industry in revenue over the next decade.

China: Metal AM's fastest growing region

The regional growth of the Chinese metal 3D printing market is one of metal AM's biggest stories. As the Chinese metal AM market has largely remained domestic, awareness of this fact in North America and Europe was relatively low up until the past few years, but there is no doubt that metal 3D printing has taken off in China. Chinese LPBF manufacturers have grown substantially over the past decade to serve a domestic audience that largely preferred local, cost-competitive suppliers over incumbent players like EOS and SLM Solutions. The sheer size of China's domestic industries, whether it be aerospace, manufacturing, automotive, etc., provided more than enough customers for these Chinese AM leaders to experience double-digit growth.

Their success enables them to expand to overseas customers, with several Chinese manufacturers opening European or American offices and establishing partnerships with distributors to reach customers. Given that capital cost is a major barrier to adoption for metal 3D printing, Chinese manufacturers' main value proposition of cost-competitive metal AM machines is quite attractive for end-users abroad. However, with ongoing geopolitical tensions and the levying of tariffs, that value proposition may be eroded. Still, the overall strength of the domestic Chinese market will make it an important region for AM for years to come.

Tariffs: A double-edged sword for metal AM

Currently, the implementation of tariffs is creating headwinds and tailwinds for the metal additive manufacturing industry. These tariffs are ostensibly meant to encourage domestic manufacturing in the US. For onshoring to occur, extensive amounts of automation would be required, which can be supported through metal additive manufacturing. Additionally, metal AM's fast turnaround times can help speed up timelines to set up manufacturing operations. In theory, metal AM as an enabler for manufacturing operations means that the metal AM industry could benefit from increased domestic manufacturing caused by tariffs.

On the other hand, the push and pull of tariffs creates significant uncertainty in the economy. Many companies are pulling back from capital investment during this time, which includes new manufacturing operations. Additionally, many companies are pulling back R&D spending to focus on core business operations; as such, companies are reluctant to invest in new technologies like additive manufacturing. This lack of investment could negatively impact the adoption and expansion of metal AM.

As such, tariffs may be a double-edged sword for metal AM, and it is uncertain exactly how the industry will be impacted in 2025. Economic uncertainty already caused some slowdown in the industry in the second half of 2024, and tariffs may or may not continue that trend in the next few years.

Metal additive manufacturing market forecasts and trends

IDTechEx's report, Metal Additive Manufacturing 2025-2035: Technologies, Players, and Market Outlook, forecasts future revenue, install base and materials demand for the metal AM market while carefully segmenting the metal AM technology and materials market by 10 process categories and 9 metal material categories. Additionally, IDTechEx analyzes each metal printing technology and provides detailed discussion on the metal AM materials market.

Full portfolio of available 3D printing market research

(Source: IDTechEx)

Schlagworte

3D-PrintingAdditive ManufacturingAMMetalPolymersStudy