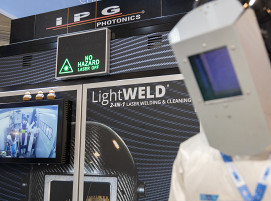

At the DVS Group's booth at SCHWEISSEN & SCHNEIDEN 2025, SLV Duisburg put a spotlight on a process that is rarely experienced live: hand-held laser beam welding. In a specially developed safety booth, visitors were able to try out the welding device themselves – after completing a mandatory safety briefing under the guidance of a welding instructor.

“The offer at the trade fair booth was very well received,” reports Heiko Hoffmann, Application Technology for Training and Education at SLV Duisburg. The booth was designed so that no laser beam could escape to the outside. Additional protective clothing was, of course, mandatory. “This way, we can safely make the process tangible here at the trade fair.”

A special highlight was a competition in which participants could demonstrate their skills. The evaluation was not limited to the weld seam surface: X-rays were also used to perform an internal evaluation of the weld seam before the winners were announced. A dedicated competition for women drew additional attention.

The mobile safety booth was not developed solely for the trade fair. In the future, it will be used nationwide to vividly demonstrate the process at companies or events. This makes a technology accessible that is becoming increasingly important in practice.

(Source: DVS Media GmbH)

Schlagworte

DVSDVS GroupHandheld Laser Beam WeldingLaser Beam WeldingPracticeSCHWEISSEN & SCHNEIDENSLV DuisburgWeld SeamWelding